The Design Method of the Secondary Filter of Cooling Water in Steam Turbine Condenser and Its Disc-shaped Filter Frame

A design method, disc-shaped technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve the problems of flow field affecting pipelines, water flow disturbance, increasing space, etc., to improve heat transfer conditions, increase vacuum, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with drawings and embodiments.

[0057] Taking a power plant condenser circulating water pipeline diameter as 1420mm as an example, the design method of the steam turbine condenser cooling water secondary filter screen disc-shaped screen frame of the present invention comprises the following steps:

[0058] (1) Determine the geometric conditions of the disc-shaped screen frame:

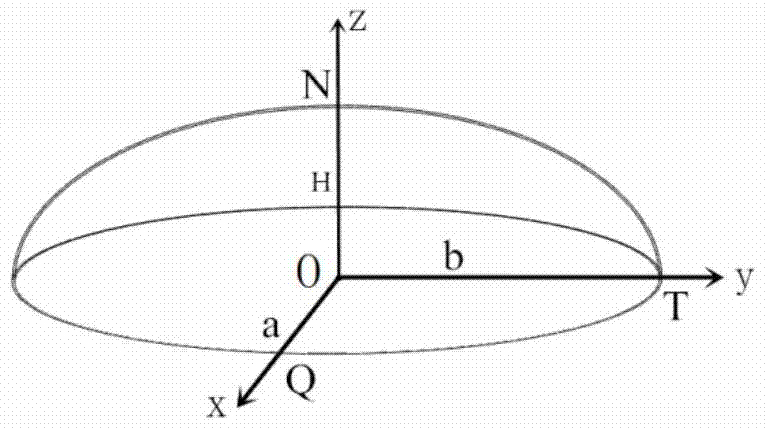

[0059] For the convenience of illustration, the disc-shaped filter frame is simplified and placed in the xyz-Cartesian coordinate system, as shown in image 3 shown. It is known that the inner radius of the circulating water pipe of the condenser of the power plant is 710mm, and the radius of the disk along the x-axis equator is a, the radius of the equator along the y-axis is b, and the polar radius is H. Then the disc-shaped filter screen frame should first satisfy: the equatorial radius of the disc along the x-axis is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com