Infrared ray quartz lamp tube heat radiation composite device

A quartz lamp and composite device technology, applied in the direction of heating elements, heating element shapes, ohmic resistance heating parts, etc., can solve the problems of lower product quality, easy edge curling, and high local temperature, so as to achieve good heating effect and improve Efficiency, the effect of reducing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

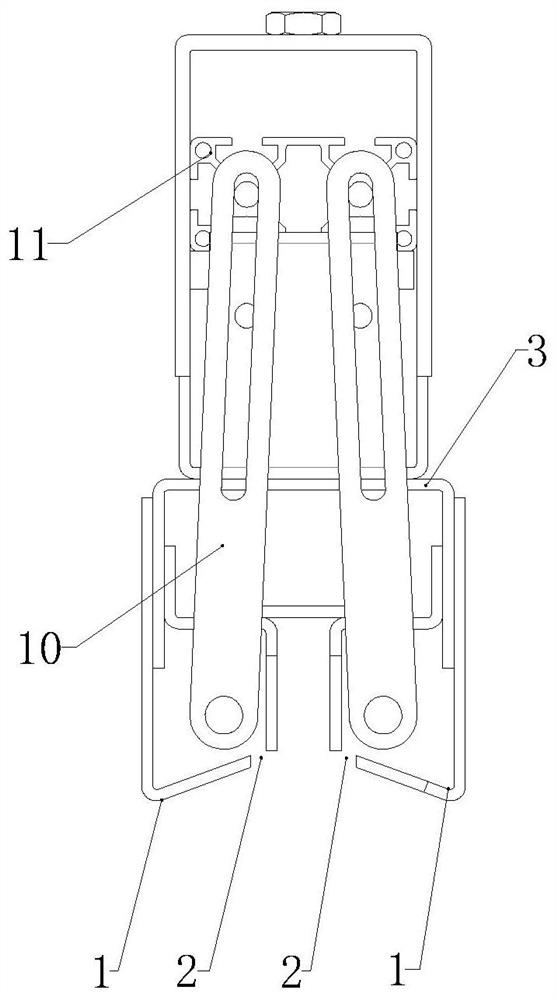

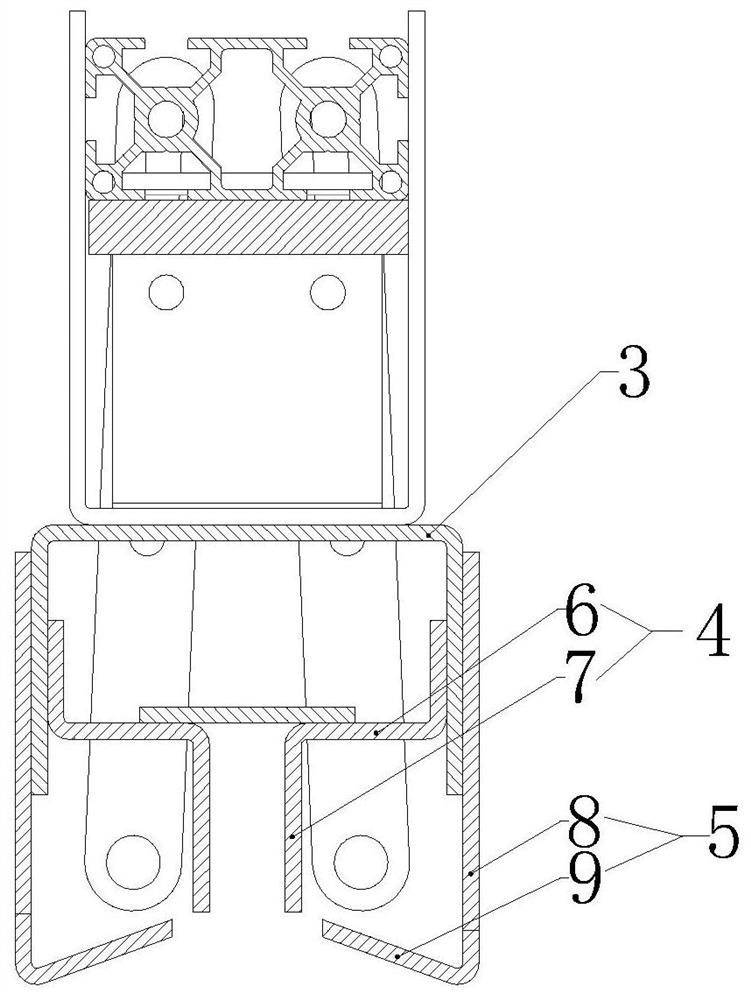

[0029] see Figure 1 to Figure 3 , the infrared quartz lamp heat radiation composite device of this embodiment includes a heating assembly, the heating assembly includes two heating chambers 1, and the heating ports 2 are respectively provided on the side walls of the adjacent ends of the two heating chambers, and the operator can pass the upper light shield or The height of the U-groove on the lower baffle plate is adjusted to realize the adjustment of the size of the heating port. A heating device is installed in the heating chamber, and the heat radiation output by the heating device can heat the heated PP sheet between the two heating chambers through the heating port.

[0030] Preferably, in the infrared quartz lamp tube thermal radiation composite device of this embodiment, the heating assembly also includes a connecting cover 3, and an upper light blocking plate 4 and a lower light blocking plate 5 are arranged on the left and right sides of the connecting cover, and th...

Embodiment 2

[0036] see Figure 4 to Figure 5 , the infrared quartz lamp heat radiation composite device of this embodiment adds a clamping assembly on the basis of the infrared quartz lamp thermal radiation composite device in Embodiment 1, the clamping assembly is located below the heating assembly, and the clamping assembly includes two Relatively movable clamping member 15 .

[0037] In this embodiment, the panel shading plate includes a vertical plate part fixedly connected with the clamping member and the square tube and a slanting plate part connected with the vertical plate, wherein the sloping plate part plays a main role of shading.

[0038] The setting of the clamping parts realizes the function of clamping, positioning and straightening the overlapping interface of the PP hollow plate to make it parallel to the lamp tube and evenly heat the heated plate. In this embodiment, the clamping part is a square tube, of which A square pipe is fixedly connected with the second installa...

Embodiment 3

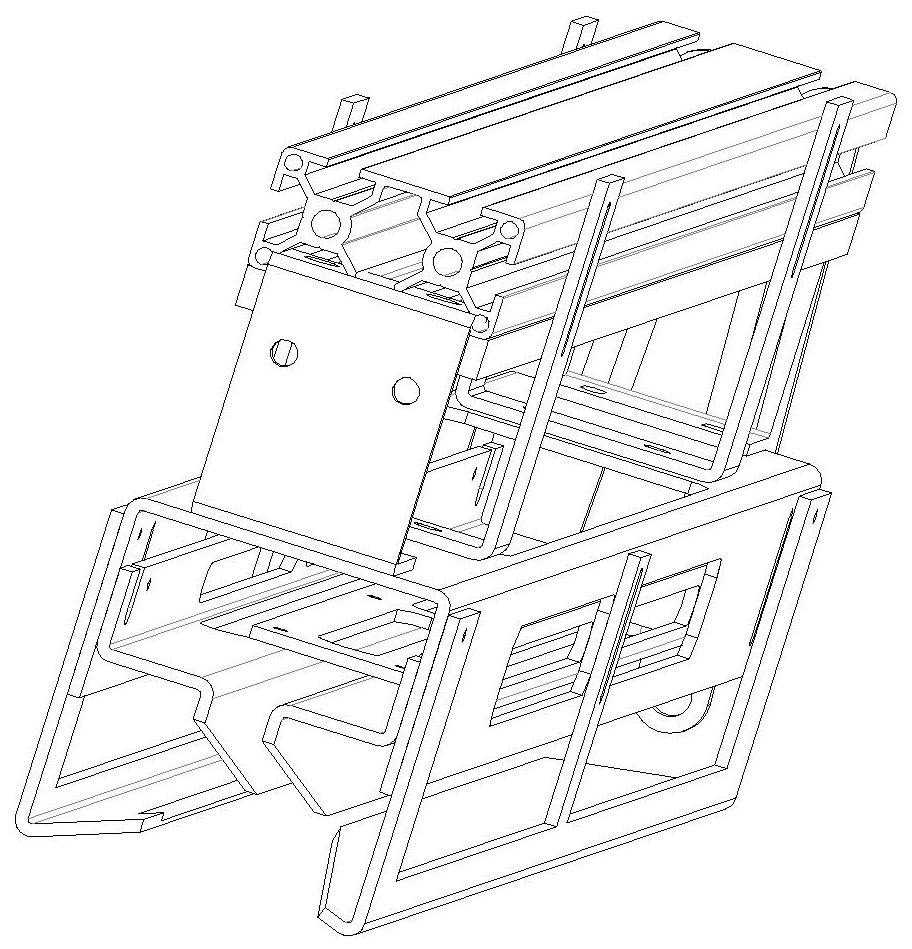

[0043] 5. see Figure 6 to Figure 8 , the infrared quartz lamp heat radiation composite device of this embodiment includes two sets of symmetrically arranged heating and clamping components, and additional components such as mounting brackets. Specifically, two sets of heating components and two sets of clamping components are symmetrically arranged on On the left and right sides, two sets of heating components are fixedly connected to the mounting frame 12 through the first mounting profile 11, and one clamping part of each group of clamping components is fixedly connected to the mounting frame through the second mounting profile 16, and each group of clamping components The other clamping part is connected with the output end of the horizontal movement drive device 17, and the horizontal movement drive device is fixedly connected with the installation frame through the connecting part.

[0044] When working, the two sides of each end surface at both ends of the plate are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com