Method for realizing interconnection between microwave signal boards and interconnected microwave signal boards

A technology of microwave signal and signal board, applied in the field of active phased array, can solve the problems of reliability and inability to meet the elastic expansion and contraction, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] There are following technical problems in the prior art:

[0040] 1. Long-distance signal vertical transmission and external vertical interconnection between boards of microwave signals;

[0041] 2. The problem of low torque plugging and unplugging of composite substrates;

[0042] 3. Disassembly and maintenance of the elastic mechanism;

[0043] 4. The problem of signal interconnection between composite substrates with excessive warpage.

[0044] In order to solve the above technical problems, this embodiment provides a method for interconnecting microwave signal boards, which specifically includes the following contents:

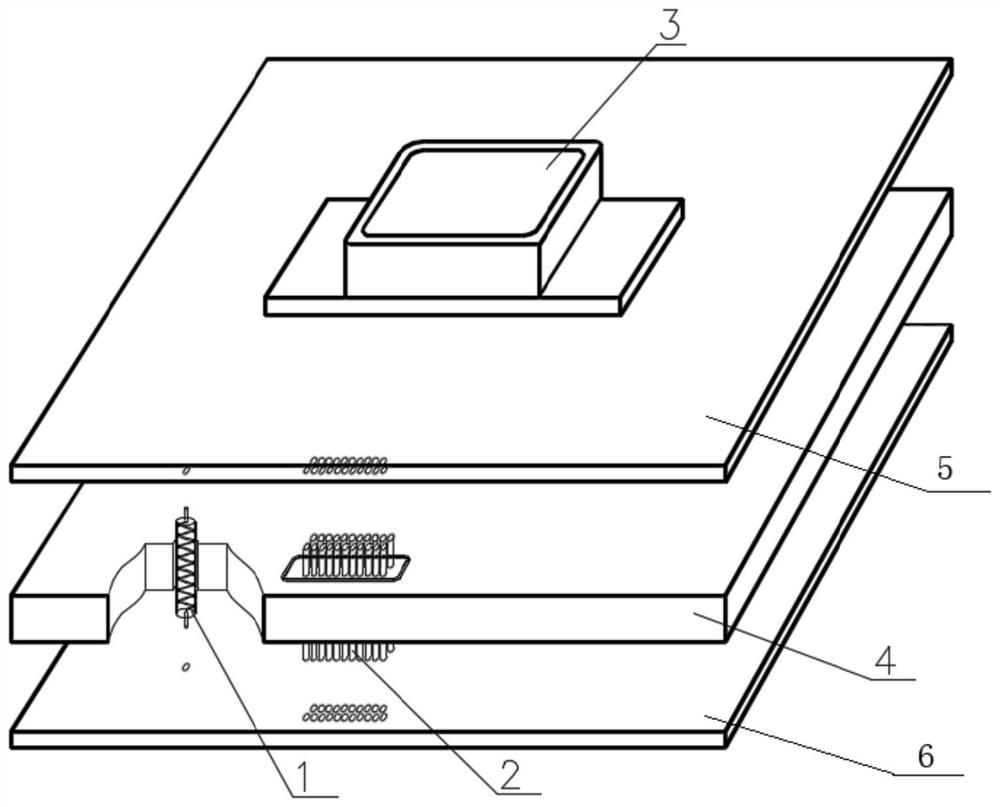

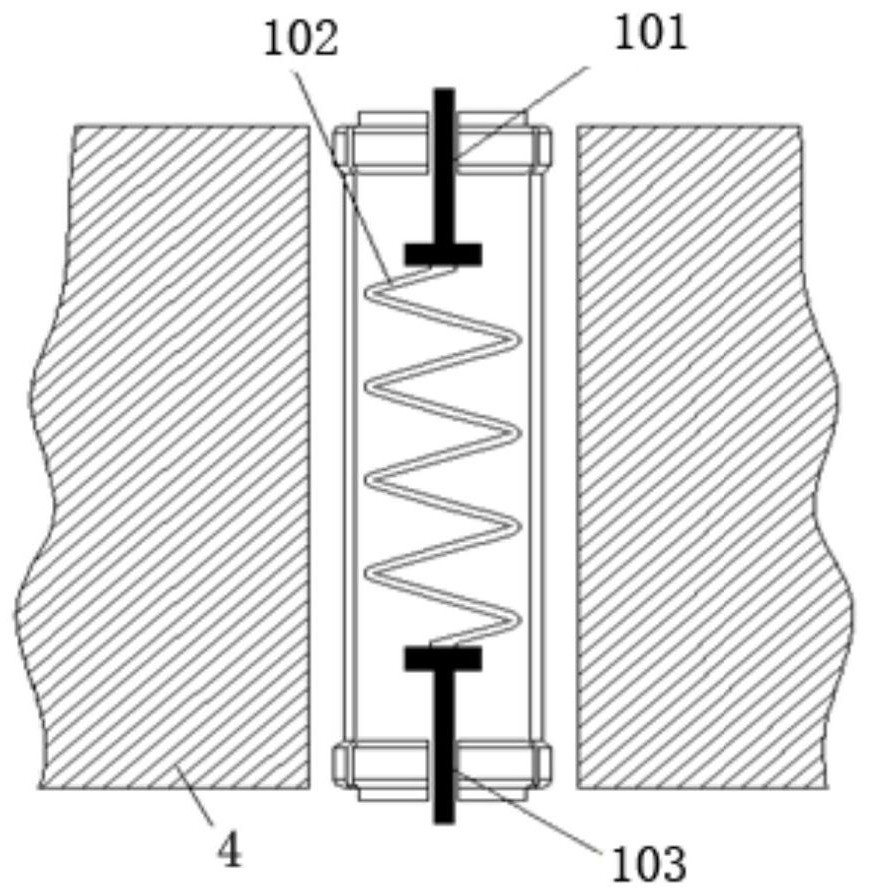

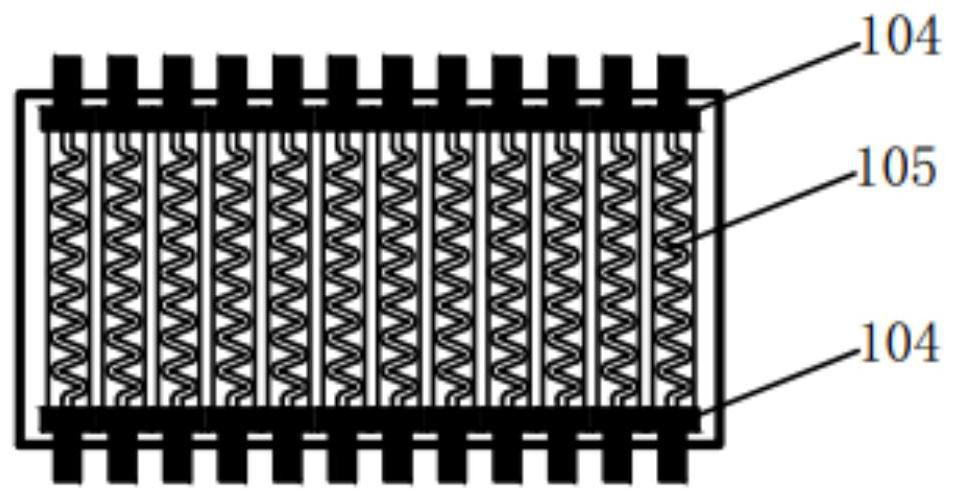

[0045] In this example, if figure 1 As shown, taking the adjacent composite substrate 1 and composite substrate 2 as an example, firstly, an interlayer adapter plate for supporting the composite substrate is arranged in the middle of the adjacent composite substrate 1 and composite substrate 2, and in the A limit hole for the limit spring connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com