Offshore thermal recovery heavy oil gathering and transportation treatment process package

A processing technology and thermal recovery technology, applied in the field of offshore thermal recovery heavy oil development engineering, can solve the problems of difficult dehydration of heavy oil, damage to equipment and sea pipes, large changes in liquid volume, etc., so as to improve the oil-water separation efficiency and shorten the residence time. , the effect of efficient processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0042] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

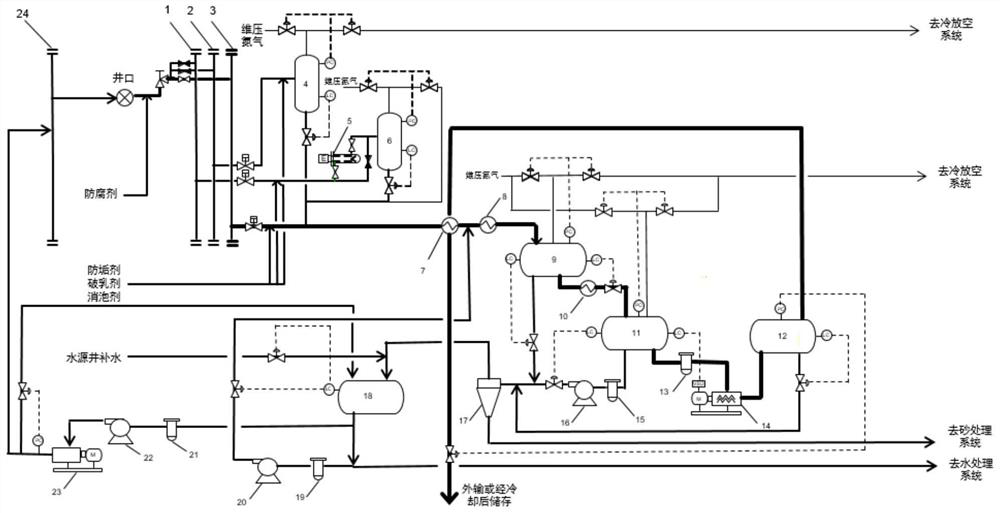

[0043] Below, the present invention is illustrated by taking a certain heavy oil field development process package in Bohai Sea as an example. The oil treatment capacity of this process package is 1909m 3 / d, using jet pump for oil extraction.

[0044] Such as figure 1 As shown, it is a schematic diagram of a heavy oil gathering and transportation treatment process package provided by the present invention, including: metering manifold 1, blowout manifold 2, production manifold 3, spray tank 4, metering heater 5, metering separation 6. Qualified crude oil / water-containing crude oil heat exchanger 7. First production heater 8. Electrostatic coalescence primary separator 9. Second production heater 10. Electrostatic coalescence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com