Gas-electricity dual-purpose heat pipe heater and method for heating oilfield wellhead

A heater and heater body technology, applied in earth-moving drilling, wellbore/well components, isolation devices, etc., can solve the problems of heat loss, parts fusing, etc., and achieve the effect of improving utilization efficiency and achieving uniform conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

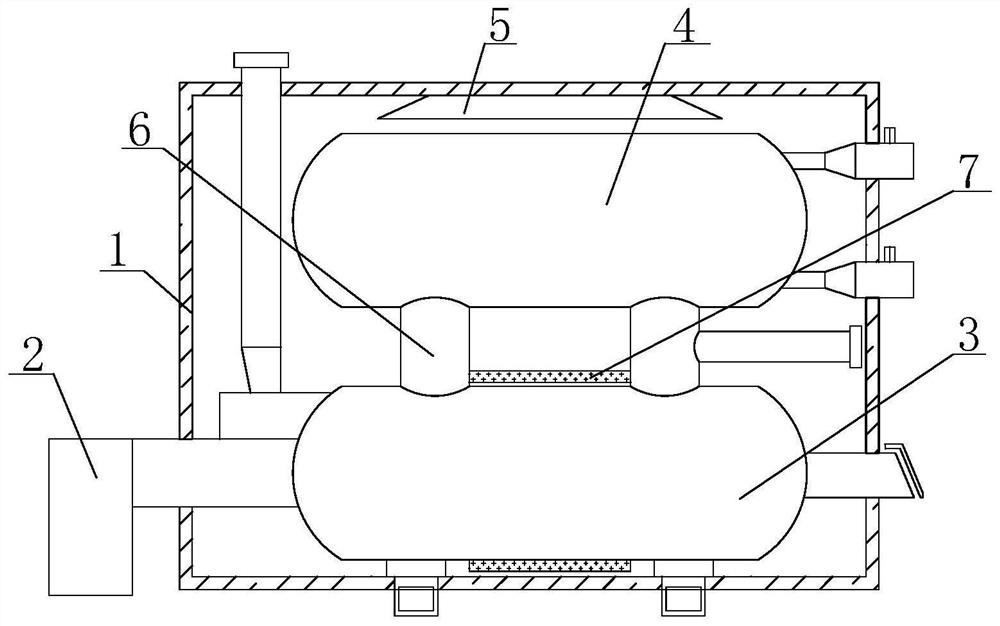

[0042] First aspect, such as Figure 1-7As shown, the present invention improves a gas-electric dual-purpose heat pipe heater for oil field wellhead heating, including a heater body 1, a burner 2, a heating cylinder 3, a heat exchange cylinder 4 and a steam-water communication pipe 6, and the heater body 1 The right side of the right side is connected to the inner wall pipe of the heating cylinder 3, the top of the heating cylinder 3 is connected to the bottom pipeline of the steam-water communication pipe 6, the top of the steam-water communication pipe 6 is connected to the bottom pipe of the heat exchange cylinder 4, and the outer wall of the heating cylinder 3 is socketed There is a thermal insulation component 7, the top of the inner wall of the heater body 1 is provided with an anti-fuse component 5, the bottom of the heating cylinder 3 is fixedly connected with the bottom of the inner wall of the heater body 1, and the top of the anti-fuse component 5 is fixedly installe...

Embodiment 2

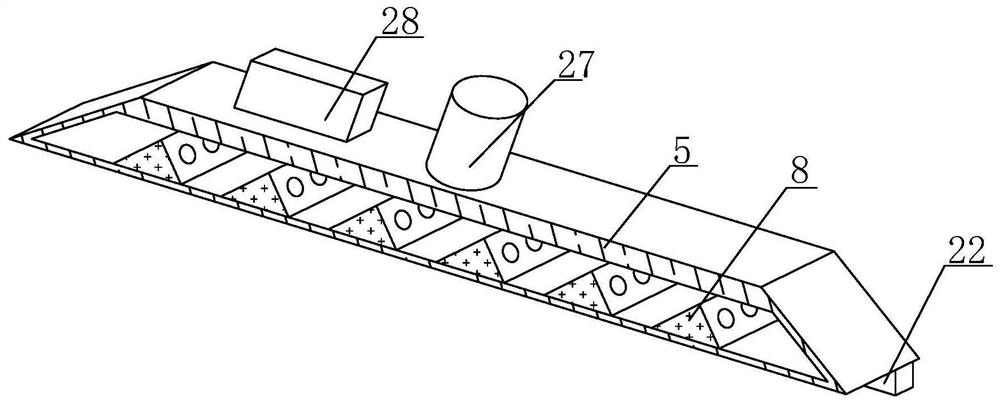

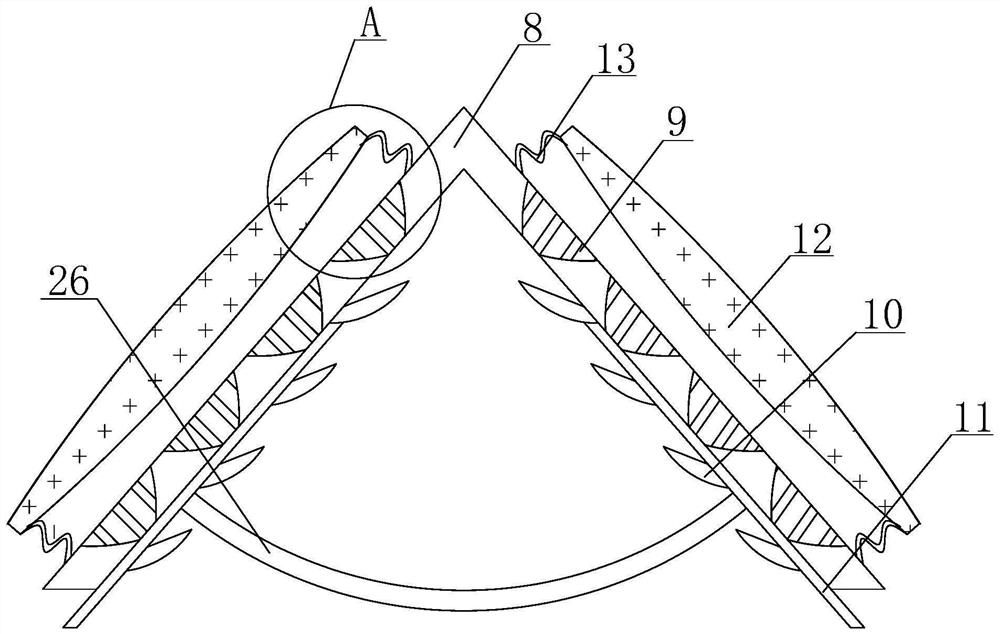

[0047] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner sidewall of the airflow contact plate 8 is provided with a guide tube 11, and the outer wall of the guide tube 11 is fixedly connected to the inner sidewall of the airflow contact plate 8 , the left side of the guide pipe 11 is provided with an angular baffle block 10, the outer wall of the angular baffle block 10 is embedded and connected with the inner wall of the guide pipe 11, and the angular baffle block 10 is used to block the water flow existing on the surface of the airflow contact plate 8 , and the water flow is introduced into the collection box 22 through the guide pipe 11, the inner wall of the airflow contact plate 8 is provided with a flow hole 9, the inner wall of the airflow contact plate 8 is fixedly equipped with an active carbon filter screen 26, and the two ends of the active carbon filter screen 26 are all connected t...

Embodiment 3

[0049] Second aspect, such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a method for a gas-electric dual-purpose heat pipe heater for oilfield wellhead heating, comprising the following steps:

[0050] Step 1: When natural gas is used as fuel or heated by an electric heating system, the energy is transferred to the heating cylinder 3 after being processed by the heater body 1, and the heat generated flows into the heat exchange cylinder 4 through the steam-water connecting pipe 6, thereby achieving the generation of the effect of heat;

[0051] Step 2: During the heating process of the heating cylinder 3, the heat generated will heat the heat conduction ring 14, and at the same time, heat the liquid inside the water flow reserved chamber 16, so that the waste heat existing on the surface of the heating cylinder 3 can be used to increase its service life ;

[0052] Step 3: When the temperature inside the heater body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com