Concrete small hollow block masonry wall worker masonry operation platform and using method thereof

A hollow block and operating platform technology, which is applied in construction, building structure, construction material processing, etc., can solve problems such as the inability to continuously adjust the height of workers' masonry, achieve convenient disassembly, reduce bending, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

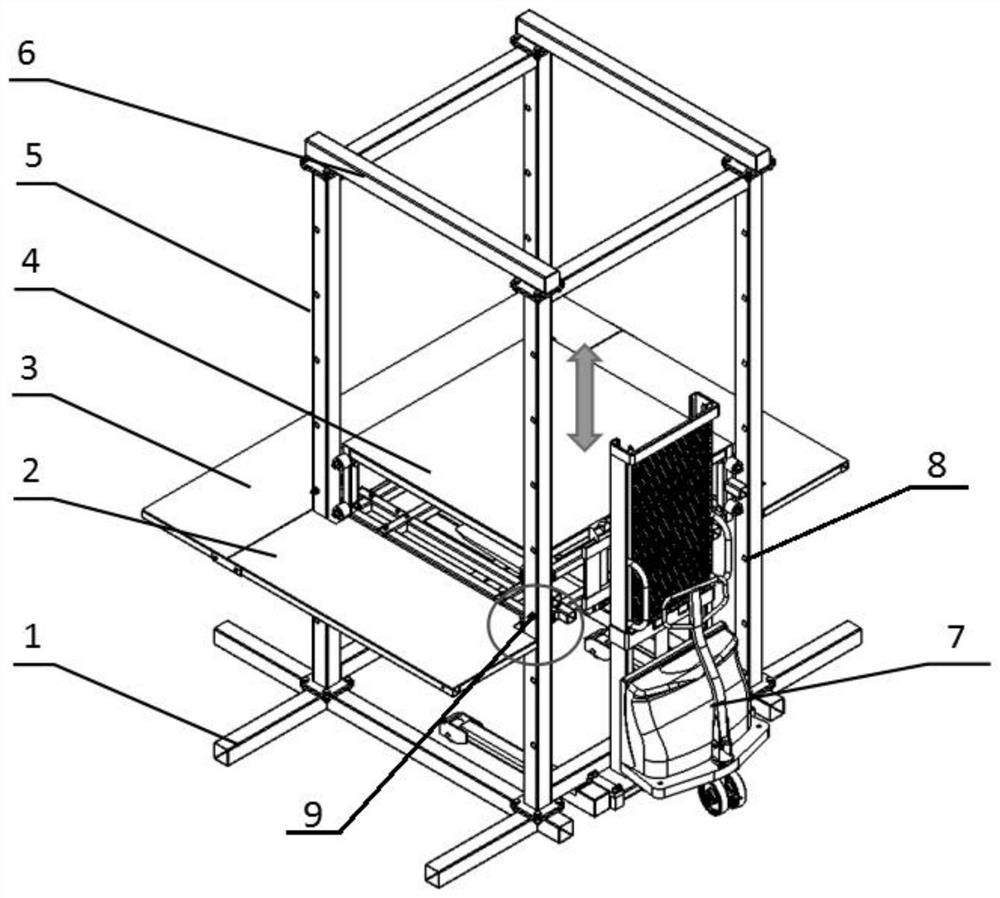

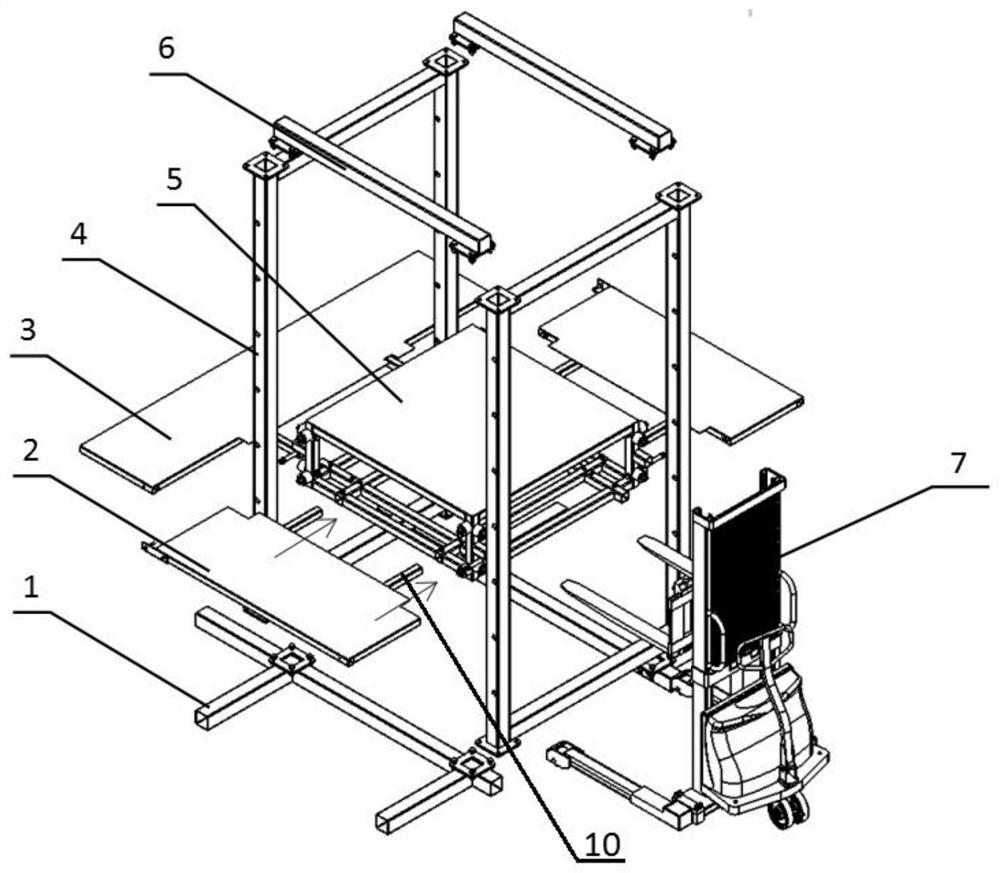

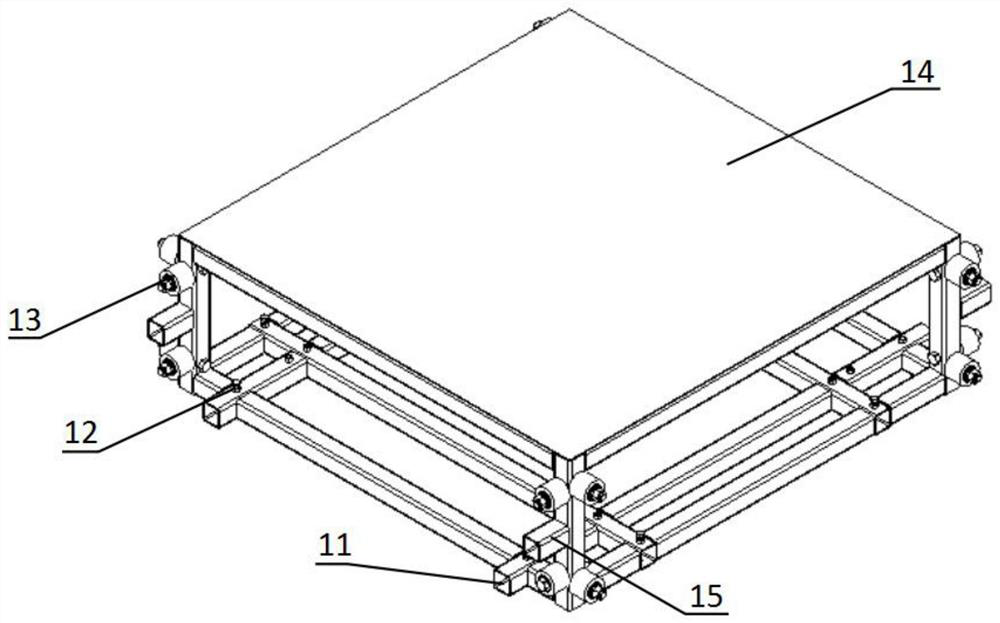

[0037] Specific implementation mode one: see Figure 1-5 This embodiment will be described. The small concrete hollow block masonry wall worker masonry operation platform described in this embodiment includes a frame main body, a number of pedals, a block platform frame 4 and a lifting device, and the block platform frame 4 is driven by the lifting device. The frame main body moves up and down, and several pedals are installed around the block platform frame 4 .

[0038] The frame body shown includes a frame base 1, four frame columns 5 and four connecting beams 6, four frame columns 5 are vertically installed on the frame base 1, and four connecting beams 6 are vertically installed on several frame columns 5. Four connecting beams 6 form a square frame.

[0039] Several pedals comprise two left and right pedals 2 and front pedals 3, and two left and right pedals 2 are respectively installed on the left and right sides of the block platform frame 4, and the front pedal 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com