A kind of composite catalyst and its preparation method and application

A composite catalyst and electrocatalysis technology, applied in the field of catalysis, can solve the problems that Pt/C catalysts are expensive and cannot be used in large-scale commercial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

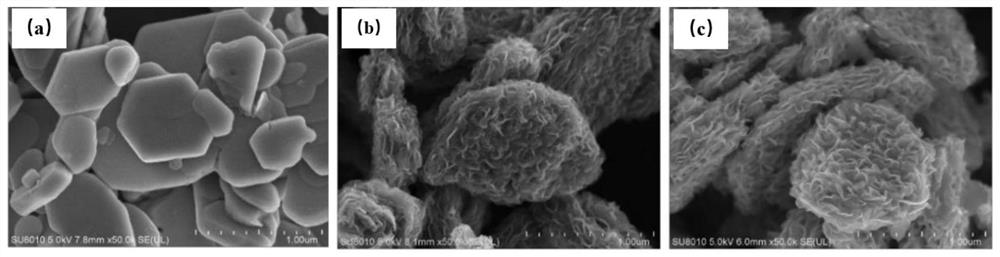

[0058] 2g Mo 2 Ga 2 The C powder was ground for 30 min, then slowly added to 20 mL of HF solution and placed on a magnetic stirring heating mantle at 55°C for 7 days. Then, the Mo was obtained by centrifugation at 10,000 rpm for 10 min. 2 CT x , wash Mo with deionized water 2 CT x Several times until the pH of the solution reaches around 6. Finally, the resulting Mo 2 CT x The powder is dried in a freeze dryer. Mo 2 CT x SEM image of figure 1 As shown in (a), it can be seen from the figure that Mo 2 CT x It is a two-dimensional sheet-like structure. Its XRD pattern is as Figure 4 shown.

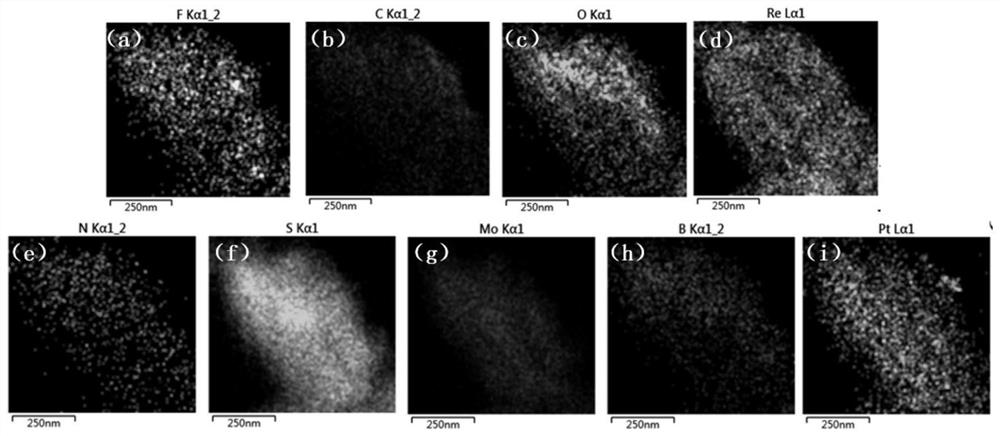

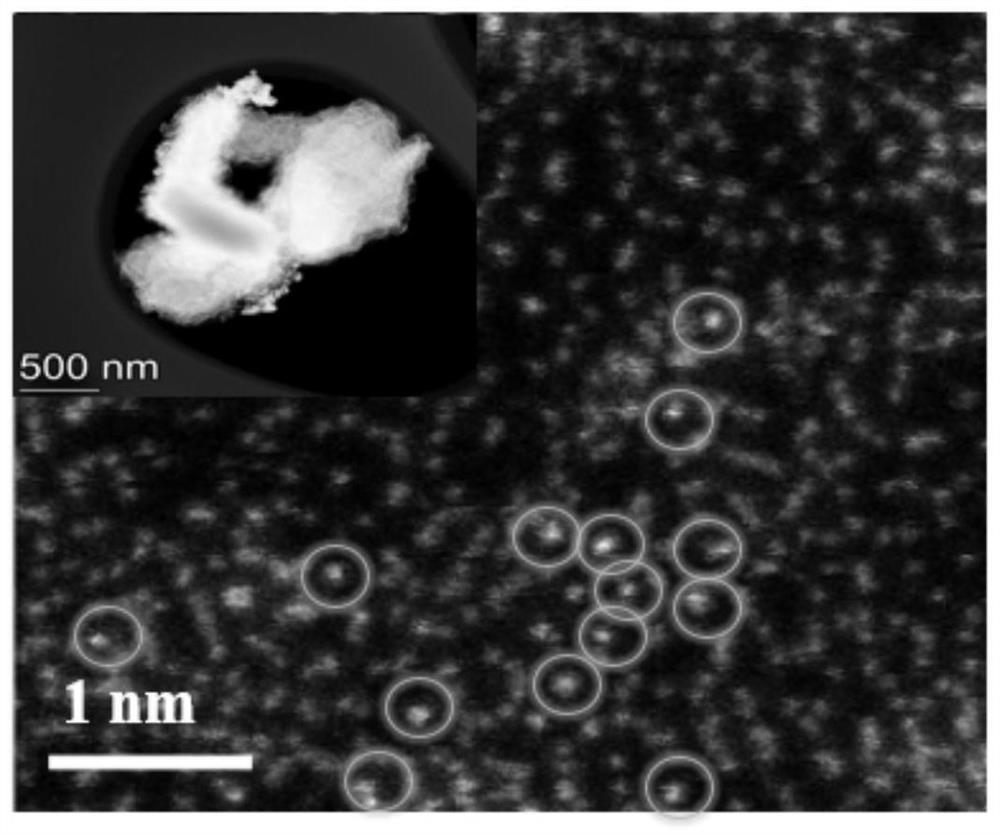

[0059] 50mg Mo 2 CT x The powder was added to 30 mL of deionized water, sonicated for 2 h, and then 322 mg of ammonium perrhenate (NH 4 ReO 4 ), 50 mg of 1-butyl-3-methylimidazolium tetrafluoroborate, 410 mg of thiourea (CH 4 N 2 S), stirred for 30min, transferred to a 50mL stainless steel autoclave, and kept at 200°C for 6h. After the reaction is completed and cooled, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com