Dispersing agent and photo-cureable 3D printing ink

A dispersant and catalyst technology, which is applied in the field of dispersant and light-curable 3D printing ink, can solve the problems of inability to widely apply organic or inorganic pigment dispersion, unfavorable dispersant storage, dispersant gel, etc., and achieve ink comprehensive performance Good, avoid gel and sedimentation, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

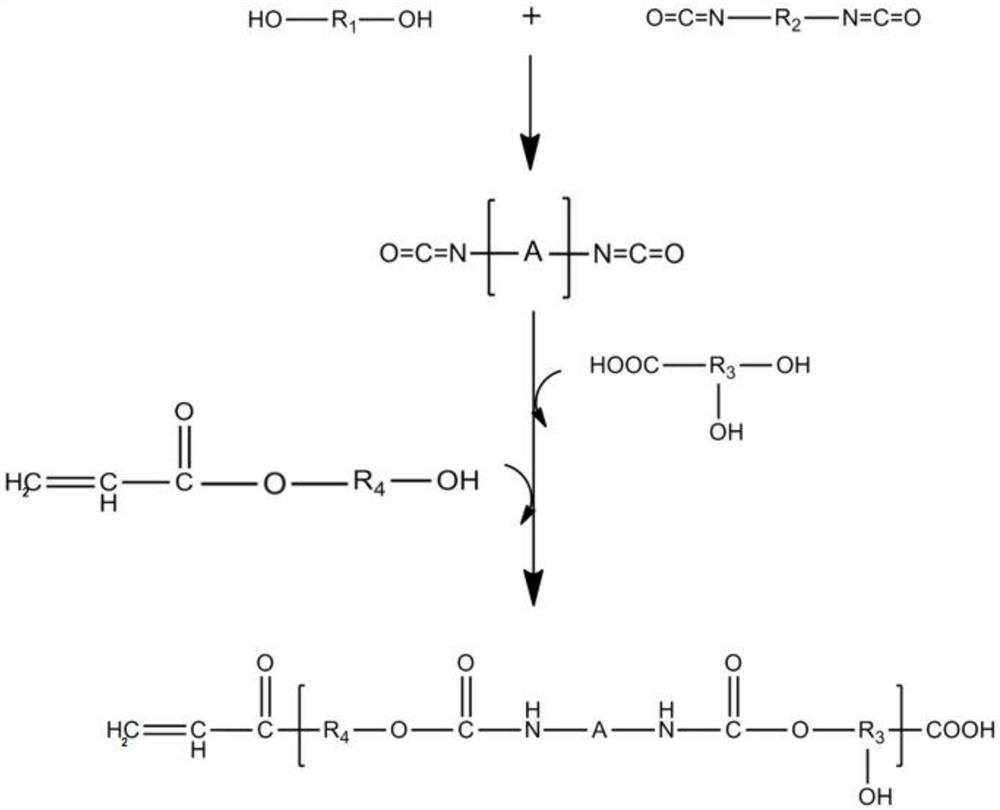

Method used

Image

Examples

Embodiment 1

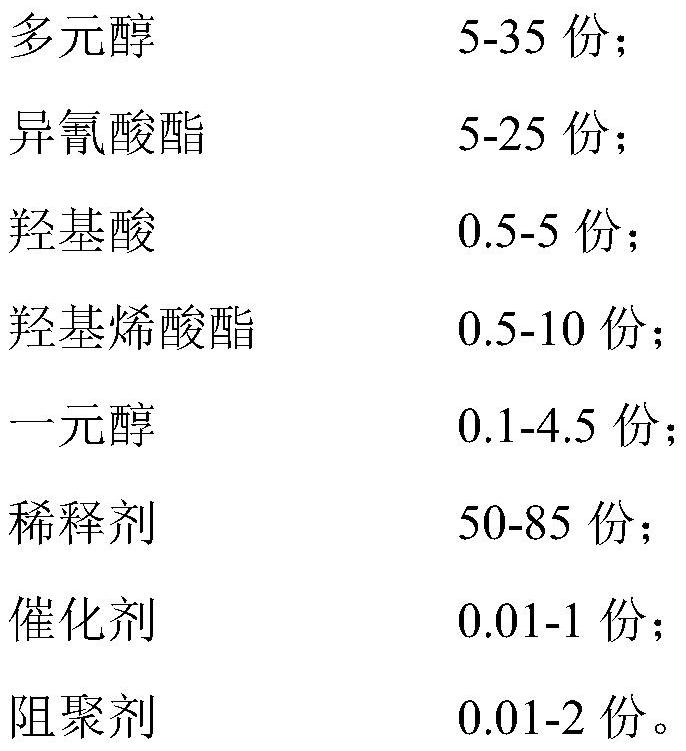

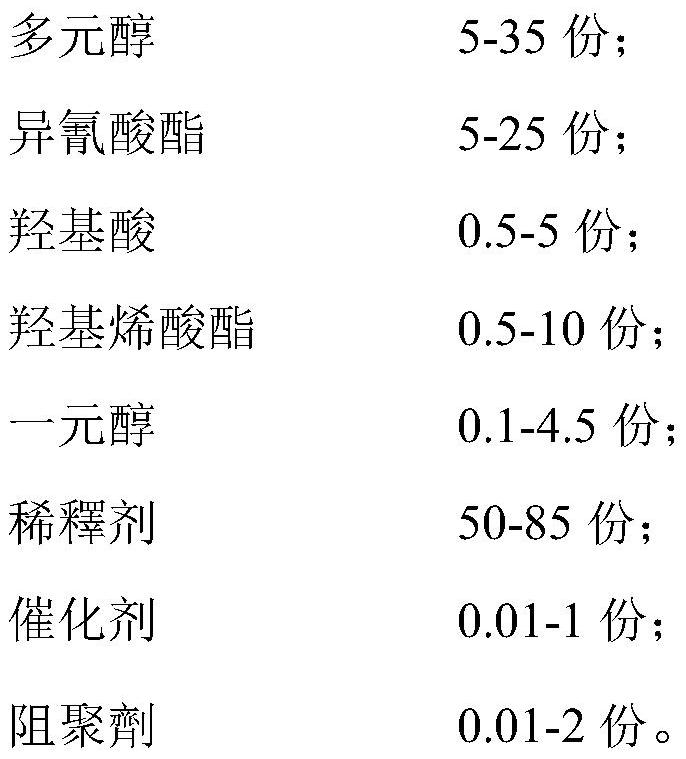

[0041] Prepare dispersant F1, comprise the steps:

[0042] (1) Add 14 parts of polycaprolactone diol, 7 parts of polypropylene glycol, and 69 parts of tripropylene glycol diacrylate into the reaction vessel, mix and heat up to 70°C, and pass nitrogen gas after the solid components are completely dissolved, and then add 0.03 Parts of dibutyltin dilaurate, 7 parts of isophorone diisocyanate, reacted at 70°C;

[0043] (2) After reacting for 3 hours, detect the NCO content. When the NCO content is less than 1.35, add 0.9 parts of dimethylol propionic acid, 1.9 parts of hydroxyethyl acrylate, and 0.07 parts of hydroquinone monomethyl ether to react at 70°C;

[0044] (3) After reacting for 3 hours, detect the NCO content, when the NCO content is less than 0.3, lower the temperature to 50°C, and add 0.5 parts of methanol to react;

[0045] (4) After reacting for 30 minutes, detect the NCO content. When the NCO content is less than 0.1, the dispersant is obtained.

[0046] The dispe...

Embodiment 2

[0048] Prepare dispersant F2, comprise the steps:

[0049] (1) Add 14 parts of polycaprolactone diol, 7 parts of polyethylene glycol, and 71 parts of 1,6-hexanediol diacrylate into the reaction vessel, mix and heat up to 70°C until the solid components are completely dissolved Introduce nitrogen, then add 0.03 parts of dibutyltin dilaurate and 6 parts of toluene diisocyanate, and react at 70°C;

[0050] (2) After reacting for 3 hours, detect the NCO content. When the NCO content is less than 1.35, add 0.9 parts of dimethylol propionic acid, 1.9 parts of 2-hydroxy ethyl methyl acrylate, and 0.07 parts of hydroquinone monomethyl ether in Reaction at 70°C;

[0051] (3) After reacting for 3 hours, detect the NCO content, when the NCO content is less than 0.3, lower the temperature to 50°C, and add 0.5 parts of methanol to react;

[0052] (4) After reacting for 30 minutes, detect the NCO content. When the NCO content is less than 0.1, the dispersant is obtained.

[0053] The dis...

Embodiment 3

[0060] The preparation of 3D printing ink comprises the following steps:

[0061] According to the ratio in Table 1, uniformly mix the dispersant, filler, and 1 / 4 portion of the diluting monomer, then use a three-roller rolling machine to roll and disperse the color paste, and then add the reactive resin and the remaining amount of diluent in sequence. After the monomer, photoinitiator and additive are mixed and stirred evenly, the 3D printing ink is obtained, which is recorded as S1.

[0062] Raw material composition of 3D printing ink S1 in Table 1 Example 3

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com