Transfer printing forming method for metallized circuit of plastic part

A molding method and metallization technology, which is applied to the printing of special varieties of printed matter, copying/marking methods, ink transfer from original manuscripts, etc., can solve the problems of difficult to make a high-gloss surface, long laser laser process, and product surface discoloration, etc. problems, to achieve high reliability test requirements, fast processing efficiency, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

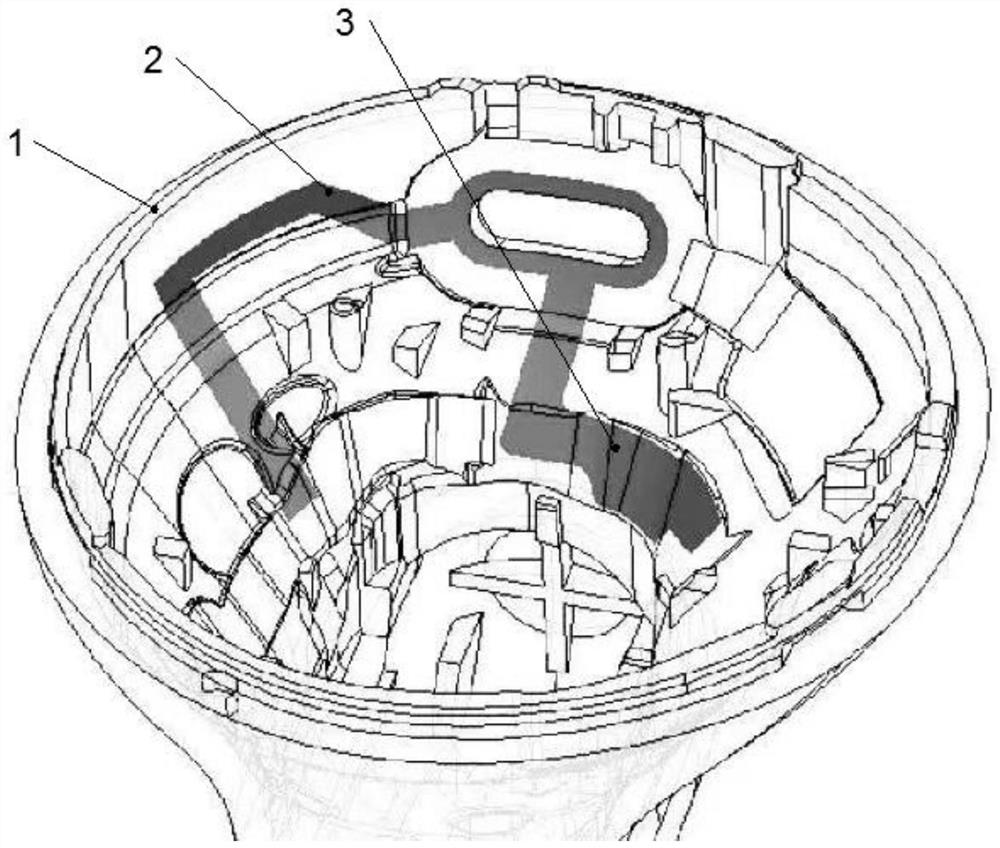

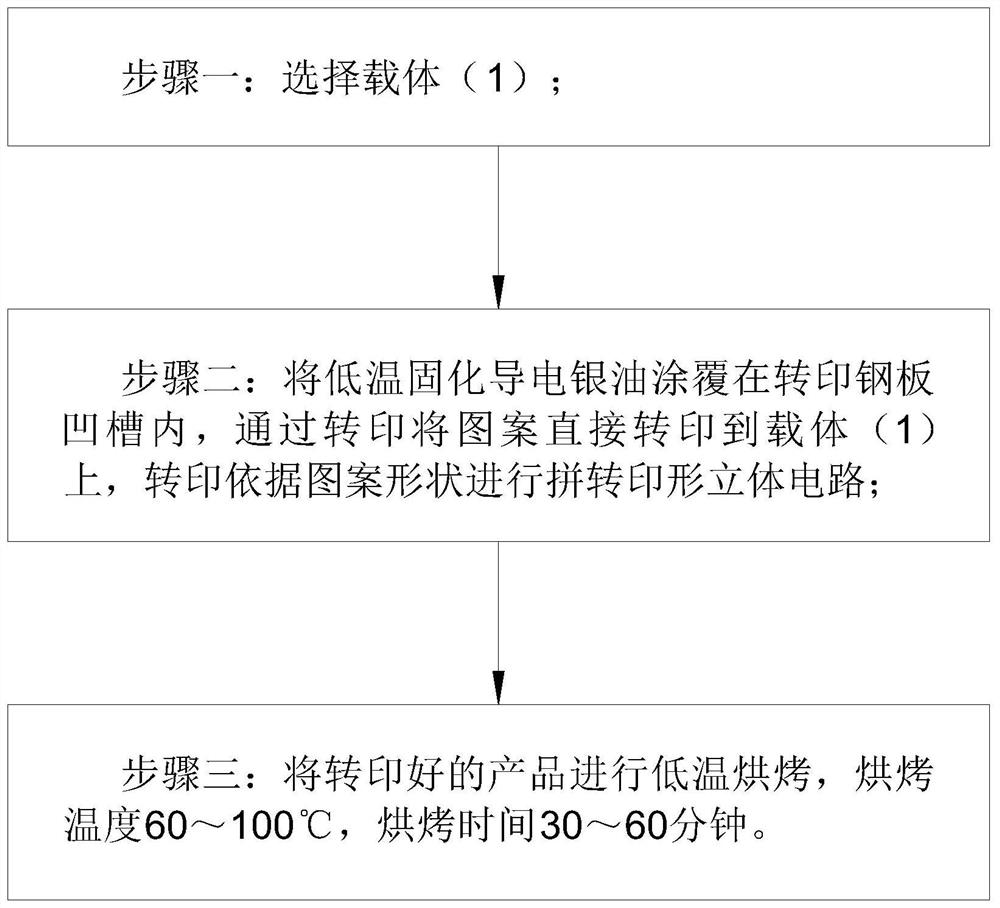

[0023] Example: such as Figure 1-2 As shown, the present invention is a transfer molding method for metallized circuits of plastic parts, comprising the following steps:

[0024] Step 1: Select carrier 1;

[0025] Step 2: Coat the low-temperature curing conductive silver oil in the groove of the transfer printing steel plate, transfer the pattern directly to the carrier 1 by transfer printing, and transfer the three-dimensional circuit according to the shape of the pattern;

[0026] Step 3: Baking the transferred product at a low temperature at a temperature of 60-100° C. and a baking time of 30-60 minutes.

[0027] Wherein, the carrier is plastic.

[0028] Wherein, the carrier is glass.

[0029] Wherein, the conductive silver oil in step 2 is polyester system conductive silver oil, and the thickness of the conductive silver oil is 0.09-0.16mm.

[0030] Among them, in step 2, the transfer printing includes antenna printing 2 and power feeding printing 3, and there is no s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com