Semiconductor wafer protection film tearing structure and operation method

A semiconductor and film structure technology, applied in the field of semiconductor wafer protection tear film structure, can solve the problems of inability to tear the film, surface rubbing of semiconductor wafers, low height, etc. block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

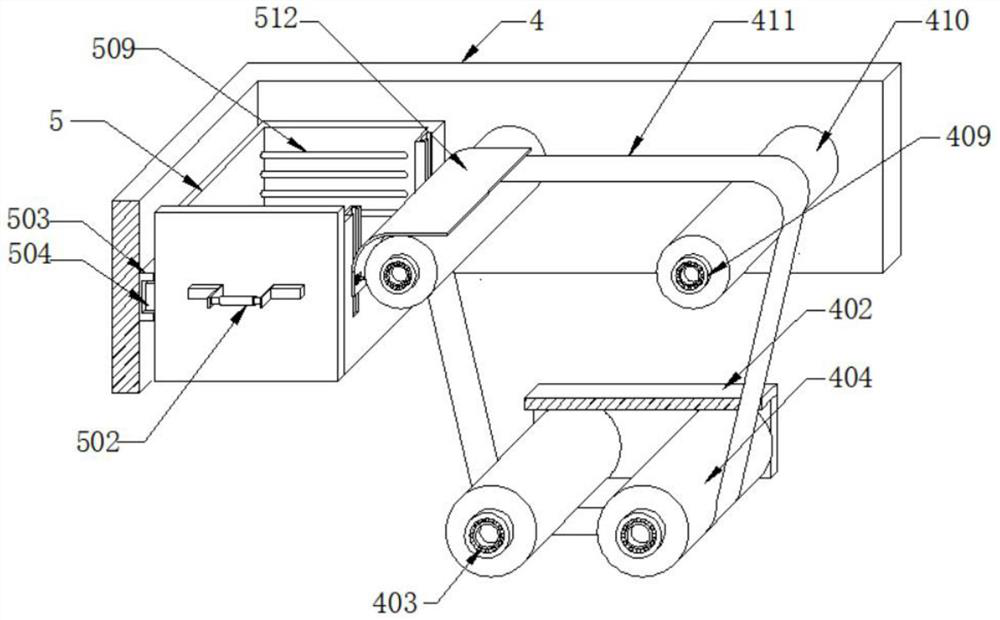

[0039] A number of hydraulic rods 401 are fixed on the top of the inner cavity of the tearing film chamber 4, and the output ends of the hydraulic rods 401 are located below. The output ends of the hydraulic rods 401 are fixed with a mounting frame 402, and the front and rear ends of the mounting frame 402 are fitted with several first bearings respectively. 403, a pressure roller 404 is fixed between the two rotating ends of the first bearing 403, at least two pressure rollers 404 are provided, a driving motor 405 is fixed on one side of the upper end surface of the mounting frame 402, and the output end of the driving motor 405 is fixed with The driving wheel 406 and one end of the pressure roller 404 run through the first bearing 403 and are fixedly connected to the rotating end with a driven plate 407, and a transmission belt 408 is sleeved between the driven plate 407 and the driving wheel 406, and the two ends of the inner cavity of the tear film chamber 4 are respectively...

Embodiment 2

[0041] see Figure 2-7 , and the difference from Embodiment 1 is that an open end 501 is provided on one side of the front end of the tearing film bin 4, and the collecting bin 5 is movably socketed with the opening end 501, and a handle 502 is fixed on the front end of the collecting bin 5, and the tearing film One side of the inner chamber of bin 4 is fixed with a chute 503 arranged in parallel, and the inner cavity of the chute 503 is socketed with a slider 504, which is fixedly connected with one side of the collection bin 5, and the middle end of the inner cavity of the collection bin 5 A partition 505 is fixed to divide the collection bin 5 into two chambers. A plurality of through holes 506 are equidistantly provided in the partition 505, and a passage 507 is provided at the center line of the partition 505, and the passage 507 is locked. A plug body 508 is connected, and a plurality of heating tubes 509 are respectively arranged on both sides of the inner chamber of th...

Embodiment 3

[0043] see Figure 4-7 The difference from Embodiment 1 is that: one end surface of the collection bin 5 close to the rotating roller 410 is provided with a plurality of locking grooves 510, and the inner cavity of the plurality of locking grooves 510 is sleeved with a locking block 511, and the locking block 511 is close to the rotating roller 410 A shovel plate 512 is fixed on the surface of one end of the shovel plate 512 and a bolt 513 is threaded inside the block 511, and one end of the bolt 513 is movably connected with the slot 510, and the shovel plate 512 can move up and down in the slot 510 through the block 511, thereby Make shoveling plate 512 can fit on the surface of adhesive tape 411, carry out shoveling operation to its surface, shoveling plate 512 upper end side arcs downwards, the protective film or viscose that can be shoveled can be sent in the collection bin 5.

[0044] It is worth noting that: the driving motor 405 in this technical solution adopts a gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com