Automatic charging and discharging mechanism

A technology of automatic loading and unloading and power mechanism, applied in the field of mechanical processing, can solve the problems of affecting processing efficiency and slow material replacement, and achieve the effect of high degree of automation, high processing stability and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as figure 1 As shown, the automatic loading and unloading mechanism described in this embodiment includes a main frame 1, and a double mechanical arm mechanism 2 is arranged above the main frame 1. The double mechanical arm mechanism 2 includes a cross arm and two sliding arms arranged on the cross arm. Two main manipulators are provided with a manipulator 5 at the end of the main manipulator; one side of one of the manipulators is provided with a tray feeding mechanism 4 that provides processing materials for the manipulator 5, and one side of the other manipulator A processing machine tool 3 is provided. A material conversion frame 6 is arranged at a middle position below the cross arm, and the material conversion frame 6 includes a rotating mechanism 7 and two storage compartments 8 arranged on the rotating mechanism 7 .

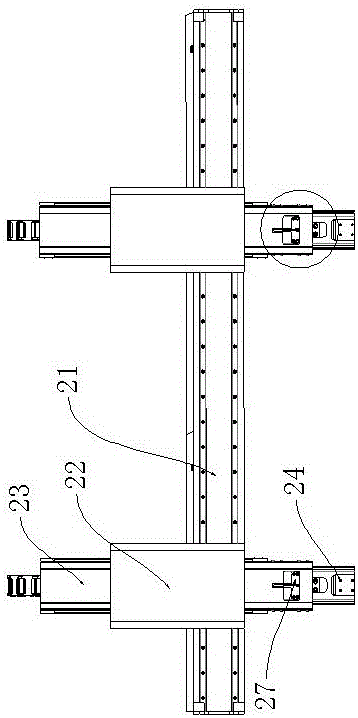

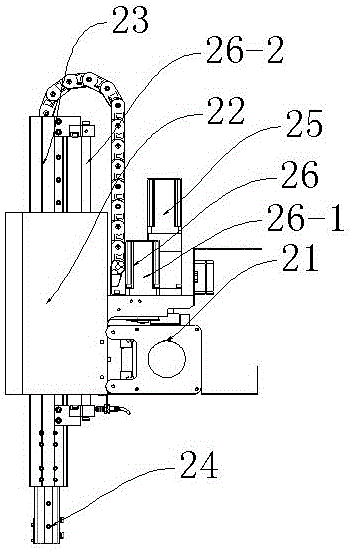

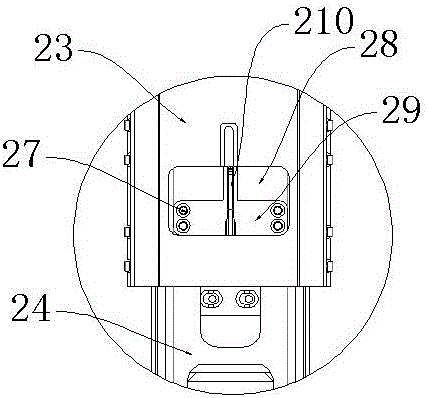

[0036] Such as figure 2 , image 3 , Figure 4As shown, the structure of the double mechanical arm mechanism 2 is to set two mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com