Preparation method of pre-tensioning method prestressed centrifugal concrete solid square pile

A concrete and prestressed technology, applied in sheet pile walls, manufacturing tools, infrastructure engineering, etc., can solve the problem that solid square piles are not resistant to driving, the overall performance of the pile structure is poor, and the axial bearing capacity of the pile body is insufficient. The problem of uniformity is achieved to facilitate production management, improve play resistance, and save production molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment discloses a method for preparing a pretensioned prestressed centrifugal concrete solid square pile, which includes the following steps:

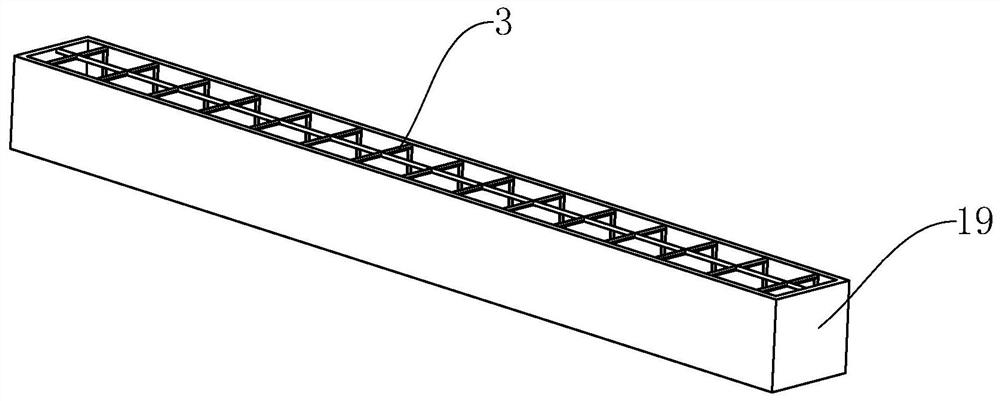

[0052]Step 1. Using a rolling welding machine with a rocker arm, the reinforcement cage 3 is prepared by using the rolling welding method of the approximate square route of the eccentric wheel. The strength loss of the welding point of the prestressed reinforcement 31 and the spiral stirrup 32 of the reinforcement cage 3 is less than the standard strength of the reinforcement. 5%.

[0053] Step 2, preparing high-performance concrete above C60.

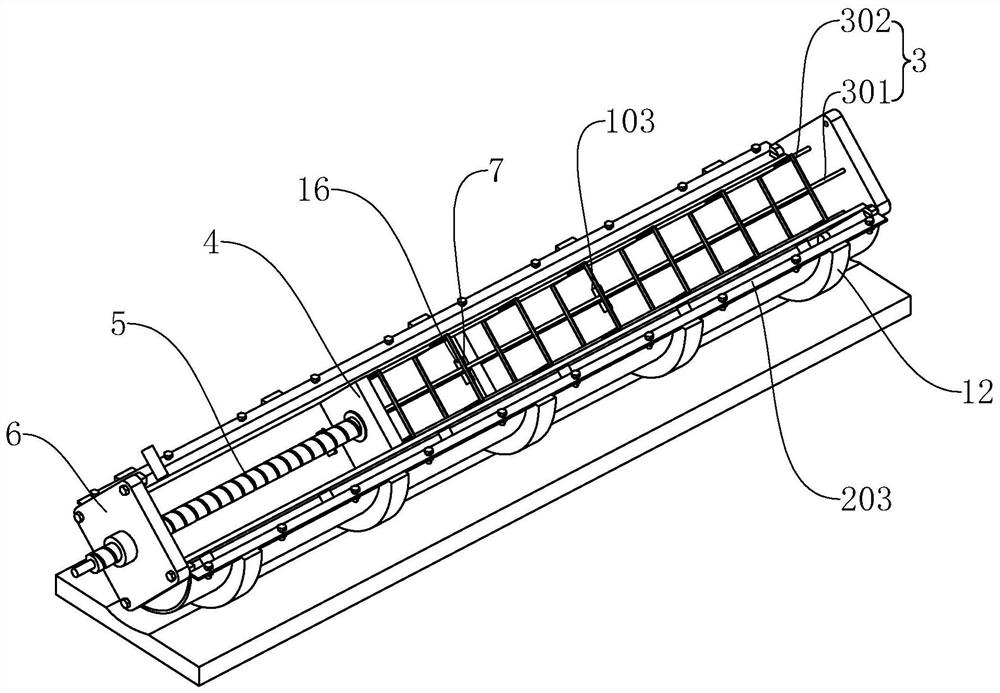

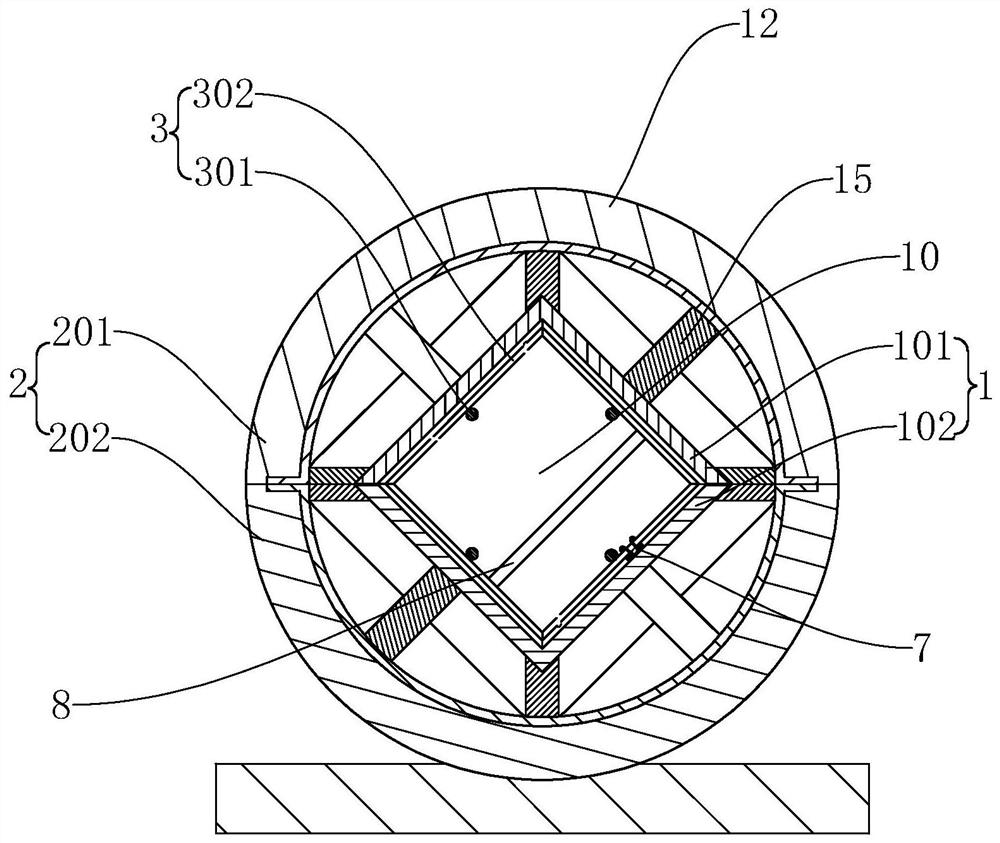

[0054] Step 3, prepare the mold, refer to figure 2 and image 3 , The steel mold includes an inner mold 1 and an outer shell 2, and the inner mold 1 and the outer shell 2 are welded through ribs 15 . The cross-section of the inner mold 1 is a square structure adapted to the square pile, the cross-section of the shell 2 is circular, and an annular rolling ring 12 is arranged...

Embodiment 2

[0069] The rest of this embodiment is the same as that of Embodiment 1. The difference is that this embodiment is different in step 4 of Embodiment 1 in order to increase the combination between the concrete of the primary centrifugal and the concrete of the secondary core filling. Refer to Figure 7 In this embodiment, after the steel cage 3 is put into the lower mold 102, multiple groups of anchor bars 9 are installed on the steel cage 3, the two ends of the anchor bars 9 are provided with a hook structure, and one end of the anchor bar 9 is connected to the steel bar through the hook. Cage 3 is connected, and the other end extends toward the center direction of reinforcement cage 3, and stretches into the connection of an end of reinforcement cage 3 center by tie bar 10 and another anchor bar 9 toward the end that stretches into reinforcement cage 3 centers.

[0070] When performing centrifugation in step 8, the anchor bar 9 is connected by the tie bar 10, and such anchor ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com