Tower drum sand blasting and rust removing device

A technology for sand blasting and rust removal and tower cylinder, which is used in grinding drive devices, used abrasive treatment devices, grinding machines, etc. It can solve the problem of poor and thick rust layers and cannot perform complete rust and rust removal. and other problems to achieve the effect of ensuring the rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

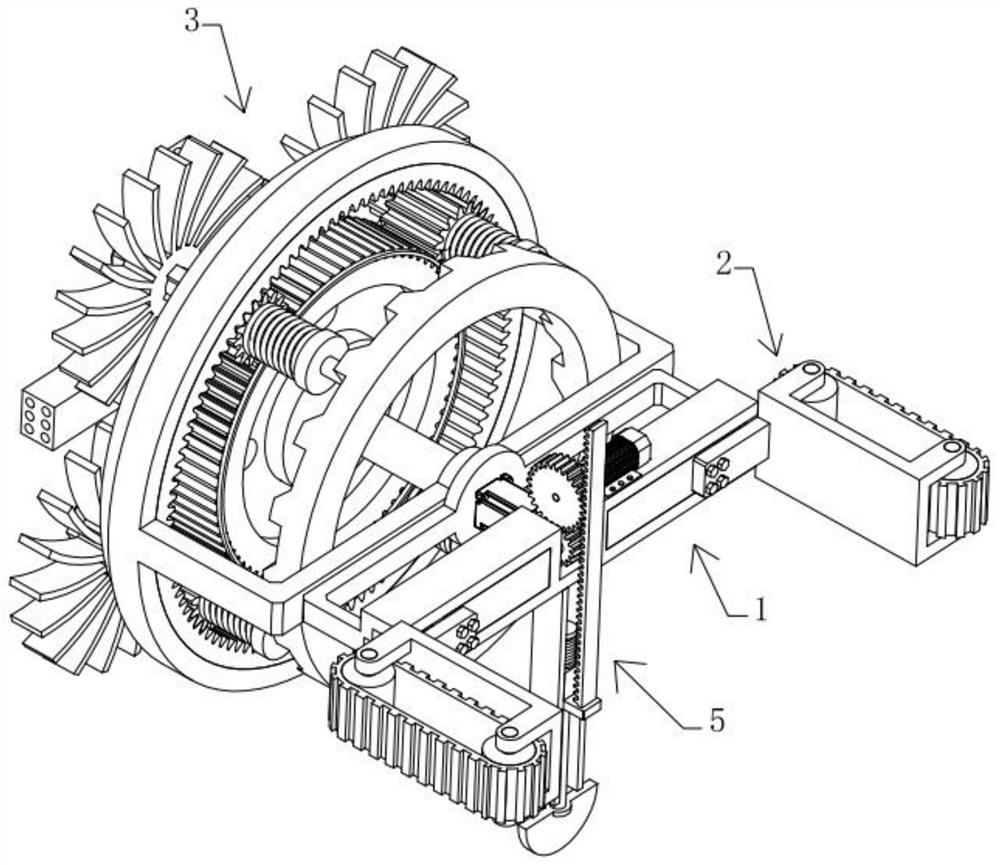

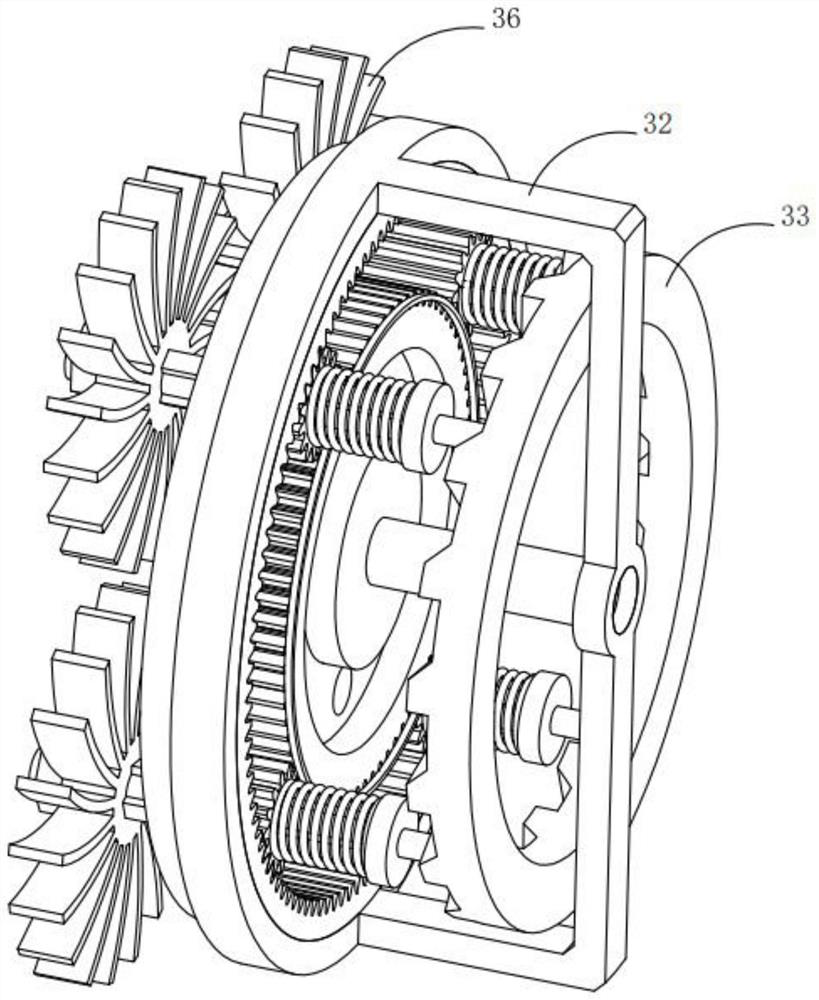

[0028] see Figure 1 to Figure 7 , the present invention provides a technical solution:

[0029] A sandblasting and derusting device for a tower tube, comprising a two-way driving mechanism 1, a crawler type traveling component 2, a friction derusting mechanism 3, a sandblasting component 4 and a sand cleaning component 5, wherein:

[0030] The two-way driving mechanism 1 includes a transverse guide rail 11, a slider I12, a two-way screw rod 13, a pinion gear 14, a large gear 15 and a motor II16. Forming a moving pair, the two-way screw rod 13 is rotatably installed in the transverse guide rail 11, wherein the two ends of the two-way screw rod 13 are threaded in opposite directions respectively through the two sliders I12 and form a threaded connection with the slider I12, and then the two-way screw rod 13 The rotation of the rod 13 can drive the two sliders I12 to move toward each other or move away from each other. The pinion 14 is fixed on the two-way screw rod 13. The mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com