Metal product weld join polishing device

A technology for metal products and mounting plates, which is used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. Grinding and other problems, to achieve the effect of convenient grinding needs, good use effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

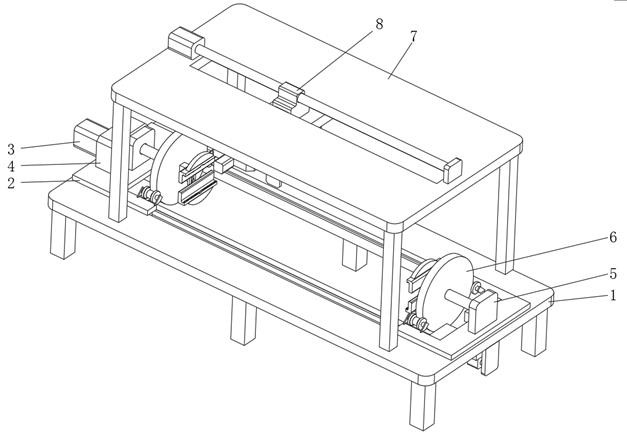

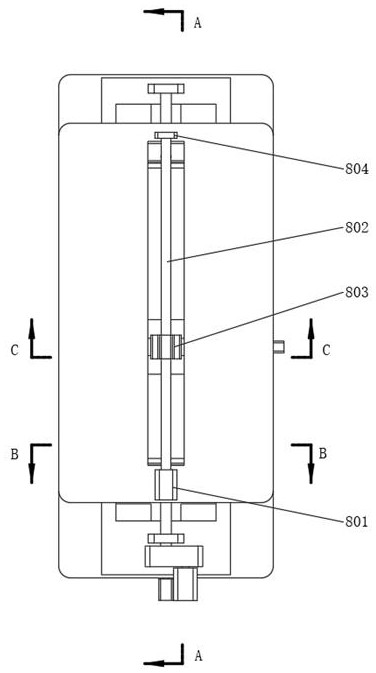

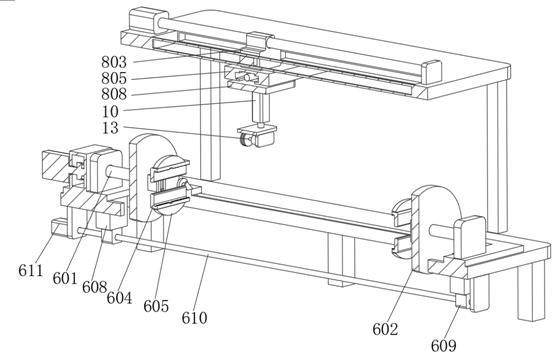

[0035] Such as Figure 1-12As shown, a welding seam grinding device for metal products includes a workbench 1, and two ends of the upper surface of the workbench 1 are slidably installed with movable mounting plates 2, and one side of one of the movable mounting plate 2 is installed with a servo motor 3, and the servo The output end of the motor 3 is provided with a gearbox 4, the other end of the gearbox 4 is provided with an adjustment mechanism 6, the upper surface of the other mobile mounting plate 2 is provided with a first fixed plate 5, and the upper surface of the workbench 1 is provided with a mounting frame 7. The installation frame 7 is provided with a direction changing mechanism 8, one end of the direction changing mechanism 8 is provided with a cylinder 10, the output end of the cylinder 10 is installed with a third fixed plate 11, and the lower end of the third fixed plate 11 is installed with a fourth motor 12 , the output end of the fourth motor 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com