Clamp for printing metal products

A product, metal technology, applied in the field of fixtures for metal product printing, can solve problems such as poor protection effect, achieve the effect of avoiding excessive clamping force, simplifying operation steps, and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

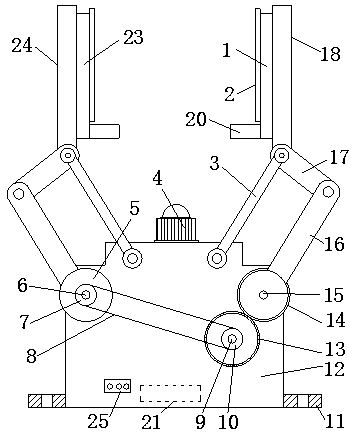

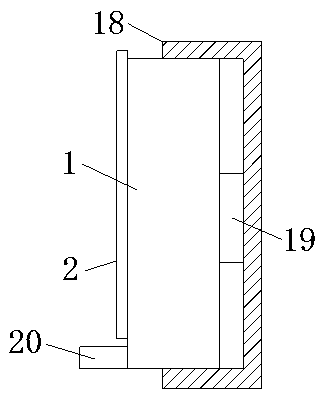

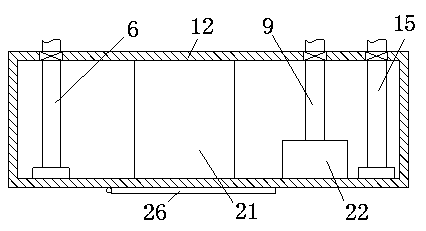

[0022]Embodiment: When in use, the workbench 12 is fixedly installed on the printing equipment through the installation hole on the fixing plate 11, and the product is placed between the first splint 1 and the second splint 23, and the bottom end of the product is in contact with the two stoppers. The support plate 20 touches the limit, and sets a preset value to the controller 21. First, the servo motor 22 is started through the control switch 25. The servo motor 22 works to drive the second rotating shaft 9 to rotate, and the rotating second rotating shaft 9 drives the second chain The wheel 10 and the full gear 13 rotate, the second sprocket 10 drives the first rotating shaft 6 to rotate through the chain 8 and the first sprocket 7, and then drives the rotating disc 5 to rotate, and the rotating full gear 13 drives the incomplete gear 14 to rotate, and then Drive the two first connecting plates 16 to swing reversely at the same time, and then drive the two second connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com