Preparation device for ceramic bond of ceramic diamond grinding wheel

A technology of diamond grinding wheel and vitrified bond, which is applied in the direction of drying gas arrangement, lighting and heating equipment, dryer, etc., and can solve the problems of simultaneous drying and grinding, short residence time of airflow, and poor drying effect, etc. , to improve drying and grinding effects, save resources and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

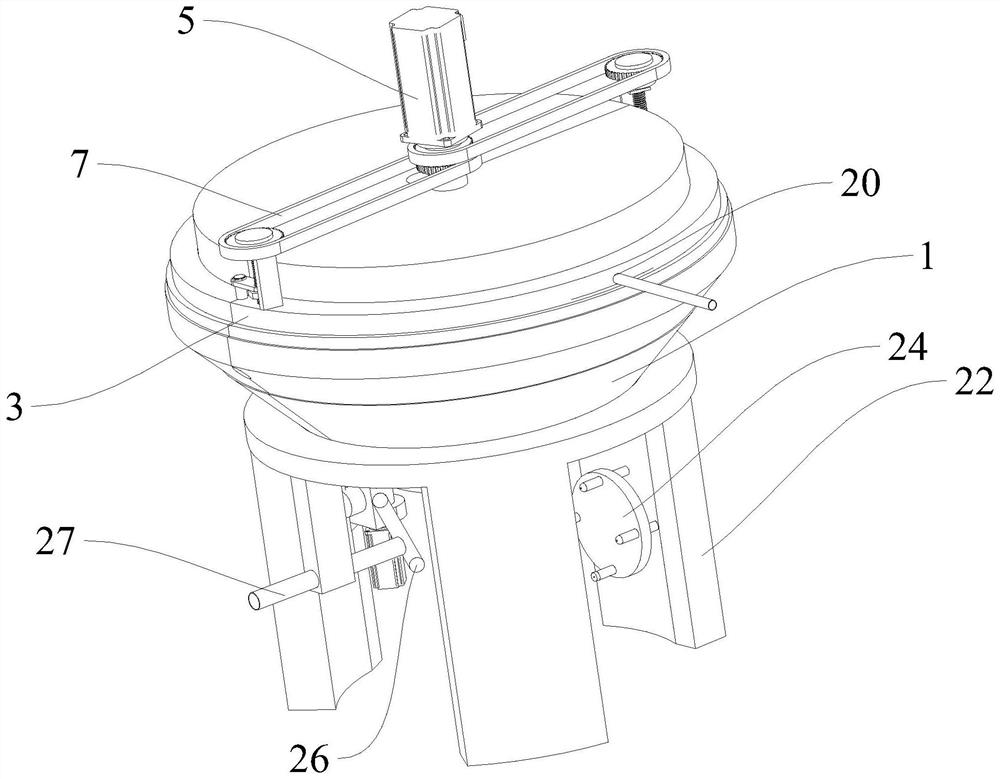

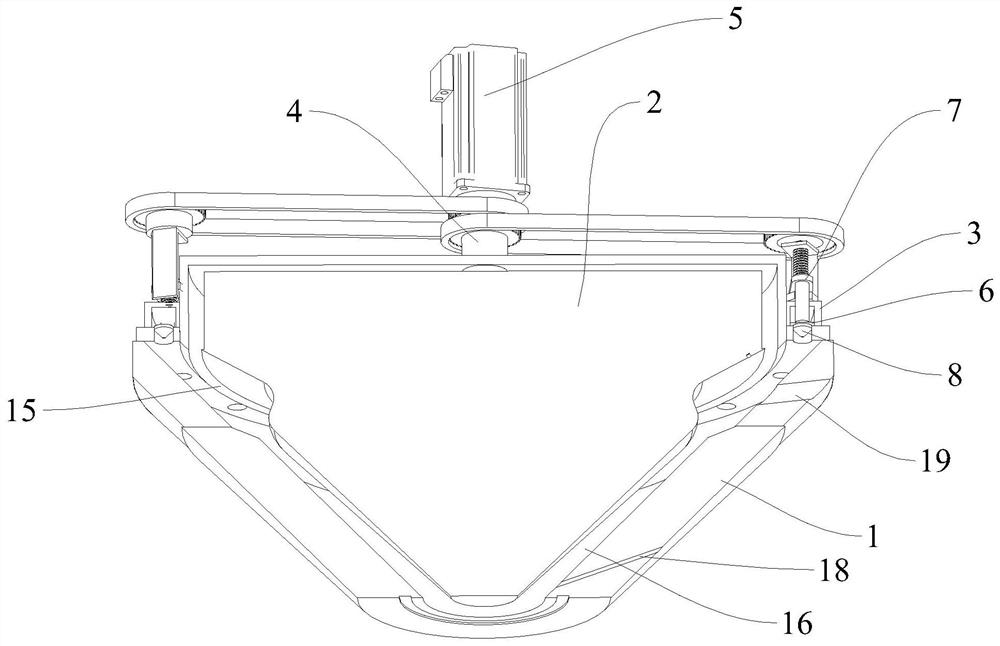

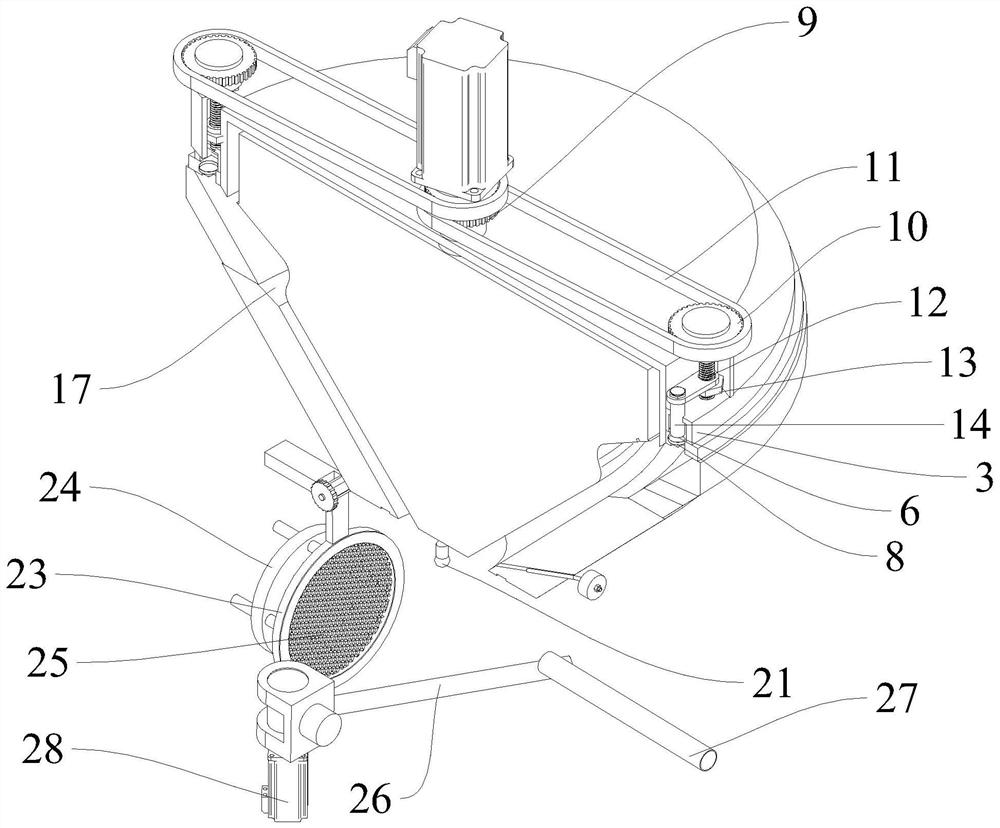

[0030] like Figure 1-Figure 4 As shown, a vitrified bond preparation device for a vitrified diamond grinding wheel includes a housing 1, a grinding disc 2 and an annular groove 3. The grinding disc 2 is arranged in the housing 1 so that it can rotate eccentrically. The rotating shaft 4 runs through the casing 1 and extends to the outside of the casing 1. The end of the rotating shaft 4 far away from the grinding disc 2 is connected with a first motor 5 for driving the grinding disc 2 to rotate eccentrically. A slidable annular piston plate 6 is arranged in the annular groove 3, and the top of the annular piston plate 6 is fixedly provided with several operating mechanisms 7 that drive the annular piston plate 6 to reciprocate. The operating mechanism 7 runs through the annular groove 3 and extends to the annular groove 3 Outer and finally connected with the rotation shaft 4, the annular groove 3 is provided with a hole for the sliding of the operating mechanism 7, and there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com