Pectin-based emulsion gel and preparation method and application thereof

An emulsion gel and pectin technology, which is applied in application, emulsion delivery, medical preparations of inactive ingredients, etc., can solve the problems of incomparable adsorption capacity with protein, low industrialization prospects, and many side reactions, etc. Achieve the effects of enriching application types, simple and easy preparation methods, and enhancing emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

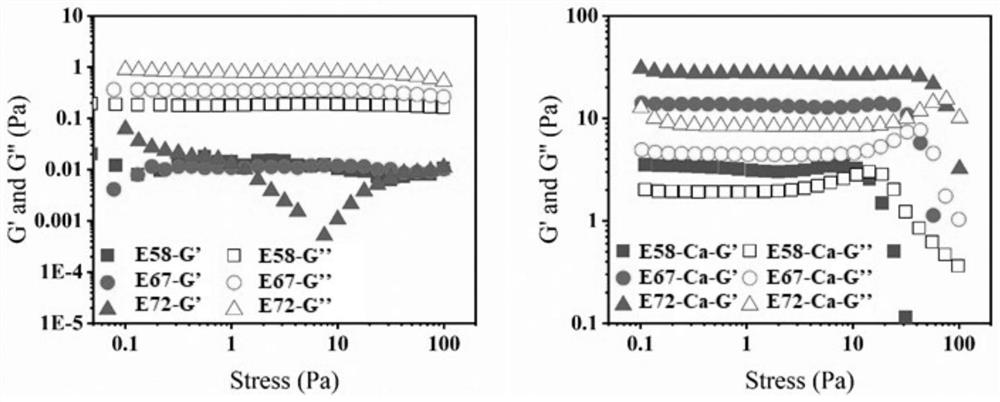

Embodiment 1

[0044] The pectin with a degree of esterification of 72% was fully dissolved in water to obtain a 1.5% (w / w) pectin solution. Adjust the pH to 3.5. Get 8mL of pectin solution and add it to a 15mL vial, add a certain volume of calcium chloride solution to a system calcium ion concentration of 5mmol / L, add soybean oil until the oil phase accounts for 20% (w / w). High-speed shearing at 15000 rpm for 2 min. The prepared emulsion gel was named as E72-Ca, and the emulsion stability, particle size and rheological properties were measured.

Embodiment 2

[0048] The pectin with an esterification degree of 67% was fully dissolved in water to obtain a 1.5% (w / w) pectin solution. Adjust the pH to 5.0. Get 8mL of pectin solution and add it to a 15mL vial, add a certain volume of calcium chloride solution to a system calcium ion concentration of 5mmol / L, add soybean oil until the oil phase accounts for 20% (w / w). High-speed shearing at 20000 rpm for 4 min. The prepared emulsion gel was named as E67-Ca, and the emulsion stability, particle size and rheological properties were tested.

Embodiment 3

[0052] The pectin with a degree of esterification of 58% was fully dissolved in water to obtain a 1.5% (w / w) pectin solution. Adjust the pH to 5.0. Get 8mL pectin solution and add in 15mL vial, add a certain volume of calcium chloride solution to the calcium ion concentration of the system respectively 5mmol / L, add soybean oil until the oil phase accounts for 15% (w / w). Under 15000rpm high-speed shearing 4min. The prepared emulsion gel was named as E58-Ca, and the emulsion stability, particle size and rheological properties were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com