Lithium ion battery composite positive electrode material, and preparation method and application thereof

A composite cathode material, lithium ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the negative impact of the electrochemical performance of cathode materials, poor electronic conductivity of fast ion conductors, and the amount of coating can not be too large, etc. problems, to achieve the effect of improving rate performance and Coulombic efficiency, eliminating residual lithium, good electronic conductivity and ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above-mentioned composite positive electrode material for a lithium ion battery, which comprises the following steps:

[0044] S1. Coating the precursor of the lithium-poor intermediate layer on the positive electrode substrate to obtain a first composite; calcining the first composite at 300-1200° C. for 0.1-30 h to obtain a lithium-poor intermediate layer covering the positive electrode substrate The positive electrode material coating of the material;

[0045] S2. Disperse the electronic conductor precursor and the ionic conductor precursor in the liquid reagent, and add the positive electrode material coating obtained in step S1, so that the electronic conductor precursor and the ionic conductor precursor are coated on the positive electrode material coating. , to obtain a second composite; the second composite is calcined in an inert atmosphere at 50 to 1200 ° C for 0.1 to 30 h to obtain a lithium-ion b...

Embodiment 1

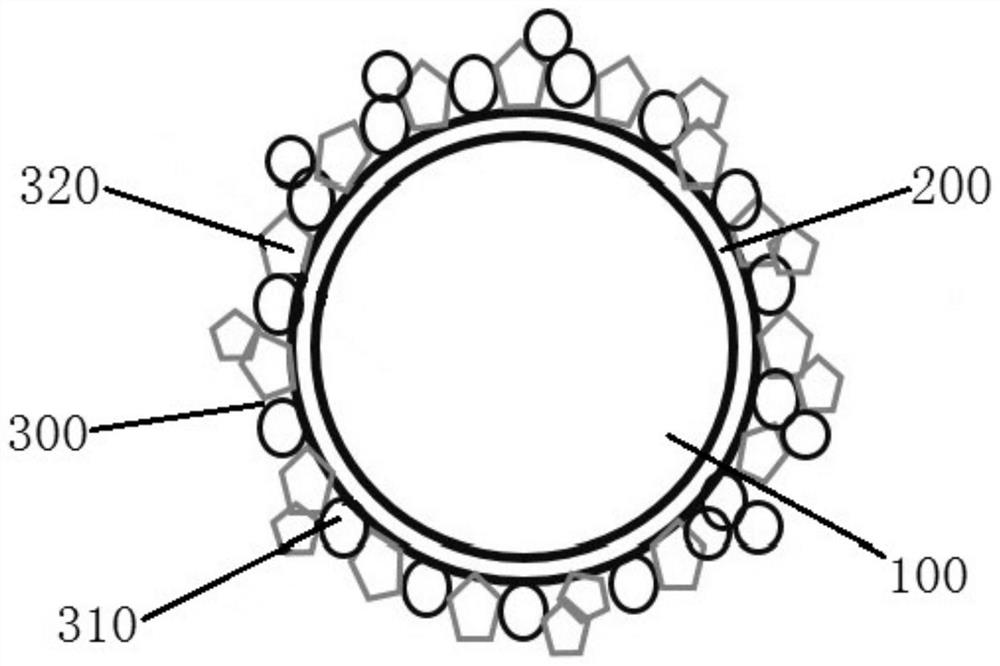

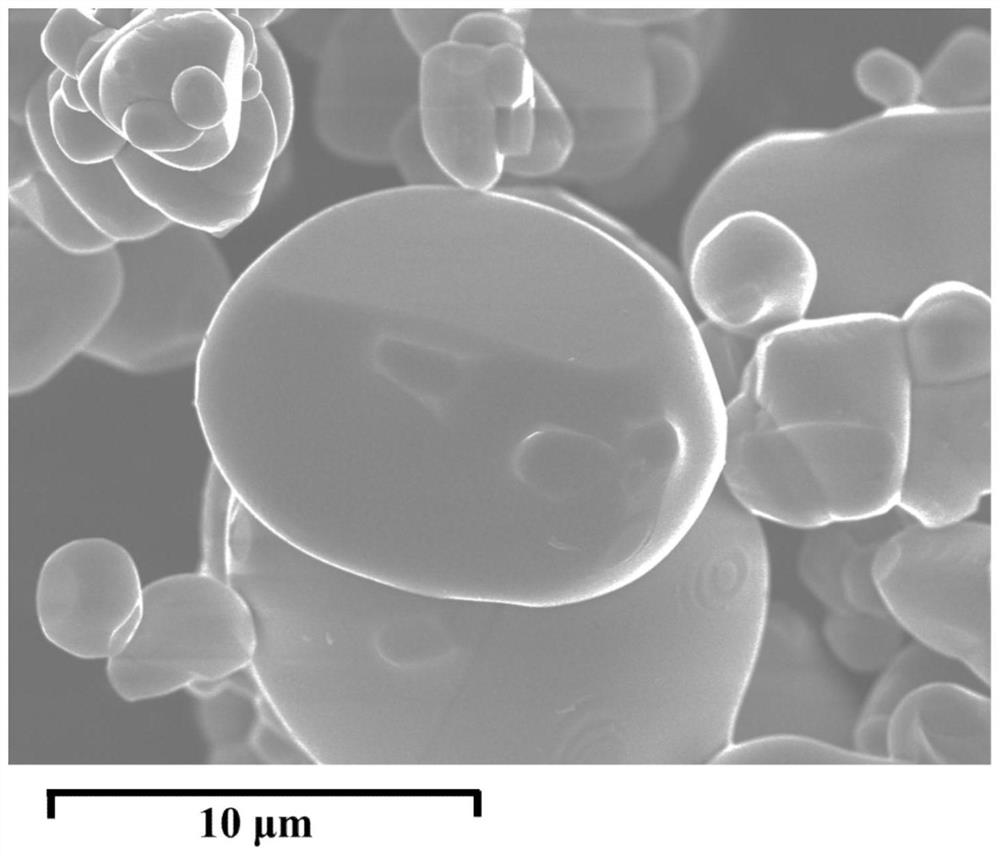

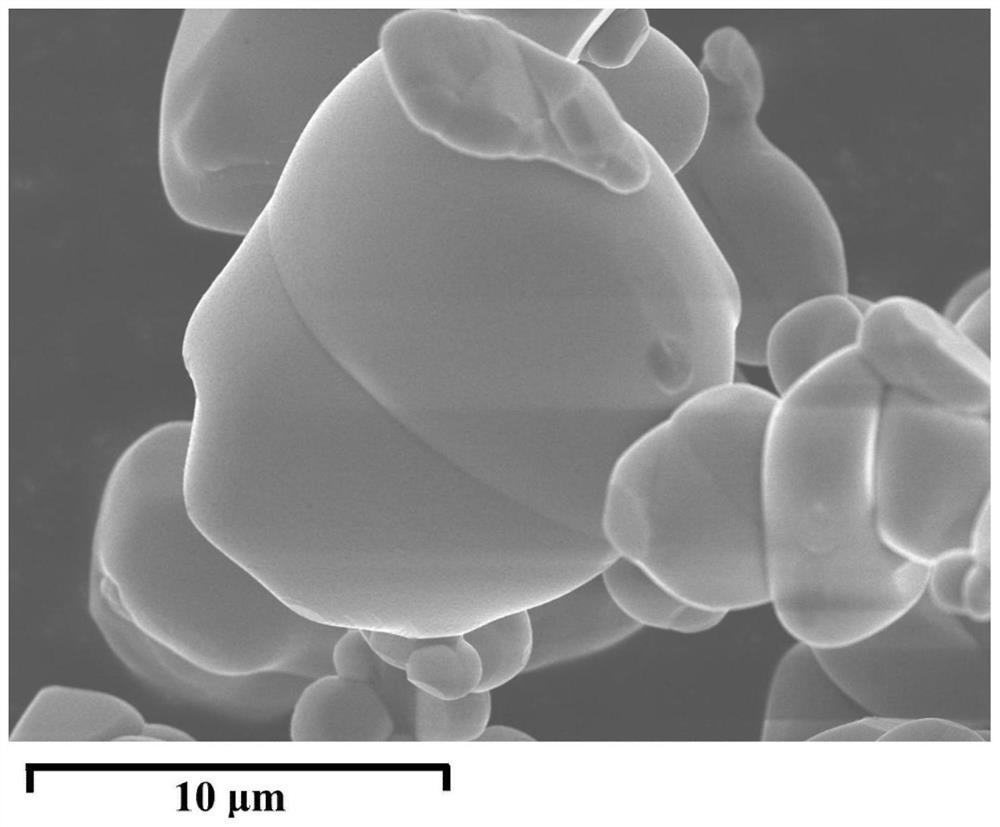

[0057] A composite positive electrode material for a lithium ion battery, comprising a positive electrode base material, a lithium-deficient intermediate layer and a composite coating layer sequentially coated on the surface of the positive electrode base material. Among them, the positive electrode base material is LiCoO with a median particle size of about 12 μm. 2 (i.e. the sample before improvement), its SEM image is as figure 2 Shown; Li-poor interlayer is Li 0.8 Ni 0.5 mn 1.5 o 4 , the electronic conductor in the composite cladding layer is graphene, and the ion conductor is Li 3 PO 4 .

[0058] The preparation method of above lithium-ion battery composite cathode material is as follows:

[0059] S1. First coat 0.004mol of lithium acetate, 0.0025mol of nickel acetate and 0.0075mol of manganese acetate on 1mol of LiCoO by evaporating the solvent. 2 (97.87g) to obtain the first composite; then the above-mentioned first composite was calcined at 850°C for 5h in an ...

Embodiment 2

[0069] A composite positive electrode material for a lithium ion battery, comprising a positive electrode base material, a lithium-deficient intermediate layer and a composite coating layer sequentially coated on the surface of the positive electrode base material. Among them, the positive electrode base material is LiCoO with a median particle size of about 12 μm. 2 Sample; Li-poor interlayer is Li 0.8 Ni 0.5 mn 1.5 o 4 , the electronic conductor in the composite cladding layer is graphene, and the ion conductor is Li 3 PO 4 .

[0070] The preparation method of above lithium-ion battery composite cathode material is as follows:

[0071] S1. First coat 0.004mol of lithium acetate, 0.0025mol of nickel acetate and 0.0075mol of manganese acetate on 1mol of LiCoO by evaporating the solvent. 2 (97.87g) to obtain the first composite; then the above-mentioned first composite was calcined at 850°C for 5h in an air atmosphere to obtain the lithium-deficient intermediate layer Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com