Evaluation method for surface rust layer after rapid rust formation of weathering resistant steel

An evaluation method, weather-resistant steel technology, applied in the direction of weather resistance/light resistance/corrosion resistance, climate sustainability, instruments, etc., can solve the problems of no better and objective evaluation method, and achieve the effect of portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A method for evaluating the surface rust layer after rapid rusting of weathering steel, the specific steps are as follows:

[0036] (1) Select Q690 steel with length × width = 10 × 5cm, and after 2 weeks of storage in an area with high humidity, obvious yellow rust appears on the surface, see figure 1 , retrieve the sample;

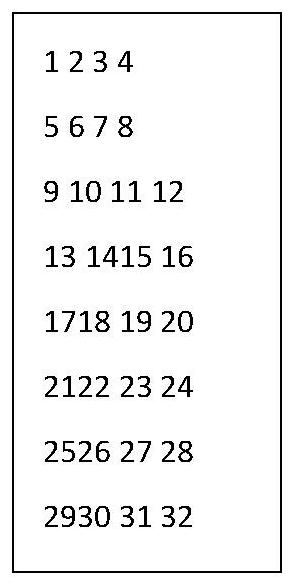

[0037] (2) Select the galvanized steel plate with length × width = 10 × 5cm to make the standard plate-grid plate, and cut the surface of the galvanized steel plate into 32 grids of the same size (length × width = 1 × 1cm), between adjacent grids The intervals are 2.5mm, and the grids are labeled from top to bottom and from left to right (such as figure 2 shown);

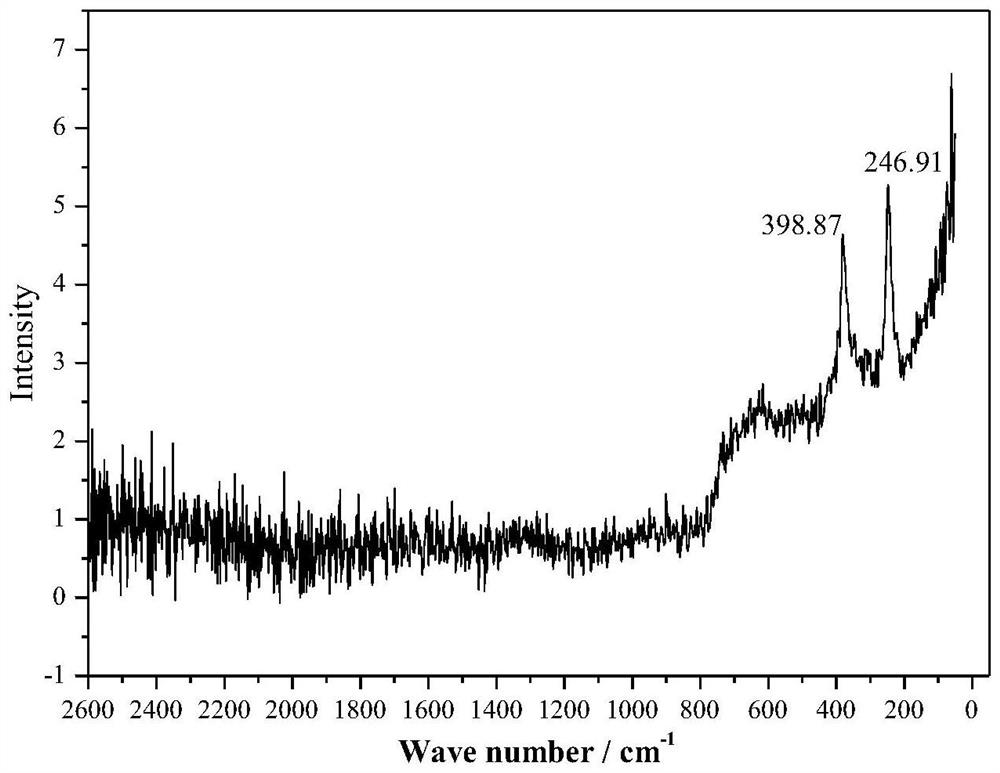

[0038] (3) Put the standard plate on the surface of the sample to be tested, and the surface of the sample is exposed corresponding to the grid of the standard plate. A total of 32 such surfaces are exposed, choose 1, 3, 6, 10, 12, 17, 19, 22, 24 , No. 27 and other 10 p...

Embodiment 2

[0050] Embodiment 2 A kind of method for evaluating the surface rust layer after weathering steel quickly rusts, the specific steps are as follows:

[0051] Choose weathering steel after two years of outdoor exposure, and a relatively uniform brown rust layer appears on the surface (see Figure 4 ), carry out the detection of Raman and color difference value according to the method of embodiment 1, the color difference value ΔE scope of detection is 65~68, median value 66, and Raman records gamma-FeOOH and α-FeOOH in the rust layer The content ratio of γ-FeOOH and α-FeOOH is between 0.8-2.3. Through statistical analysis, it is found that the median value in each group of data is representative, and the content ratio of γ-FeOOH and α-FeOOH is about 1.331.

Embodiment 3

[0052] Embodiment 3 A method for evaluating the surface rust layer after rapid rusting of weathering steel, the specific steps are as follows:

[0053] The bridge weathering steel after 8 years of outdoor exposure was selected. Without any treatment before exposure, a relatively uniform brown rust layer appeared on the surface of the weathering steel (see Figure 5 ). Carry out the detection of Raman and color difference value according to the method for embodiment 1, the color difference value ΔE scope of detection is 70-75, median value 73; Raman records the content of γ-FeOOH and α-FeOOH in the rust layer The ratio is between 0.5-1.0, and through statistical analysis, the median value of the content ratio of γ-FeOOH and α-FeOOH is about 0.725.

[0054] The rust layer of bridge weathering steel after 8 years of outdoor exposure is darker than other rust layers. According to practical experience, it can better adhere to the surface of weathering steel and is less prone to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com