Foundation pit inclined support system and foundation pit inner support construction method

A technology of oblique support and construction method, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problem that the support structure is not allowed to enter the surrounding underground soil, so as to reduce the difficulty of excavating the reserved soil and reduce the construction cost , the effect of reduced correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

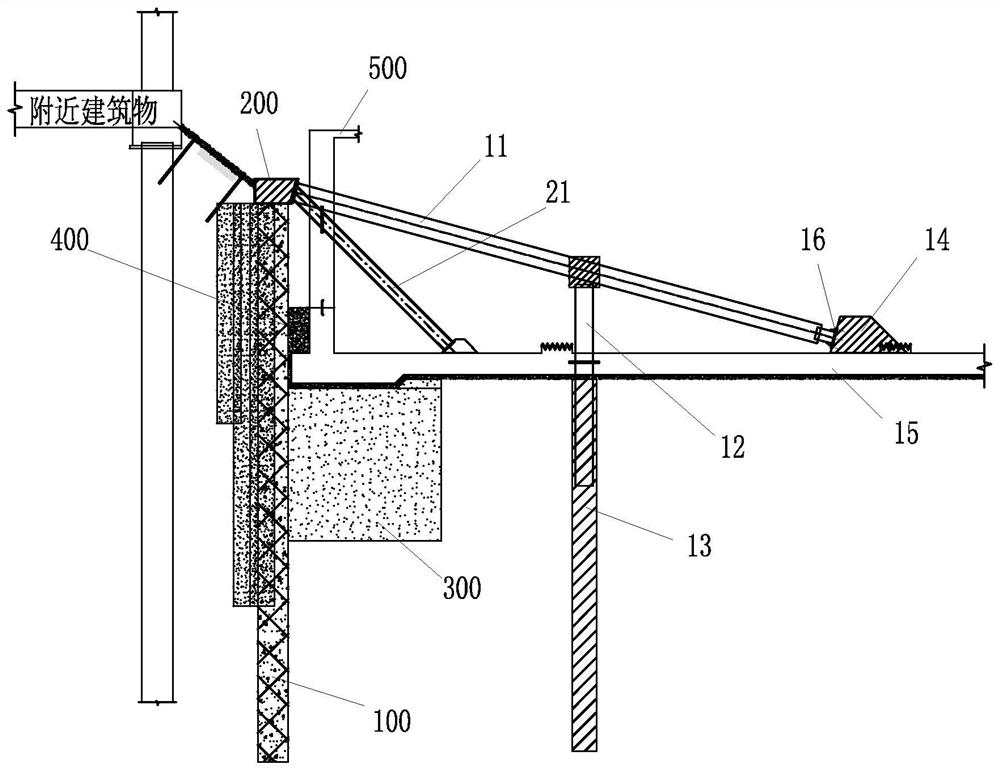

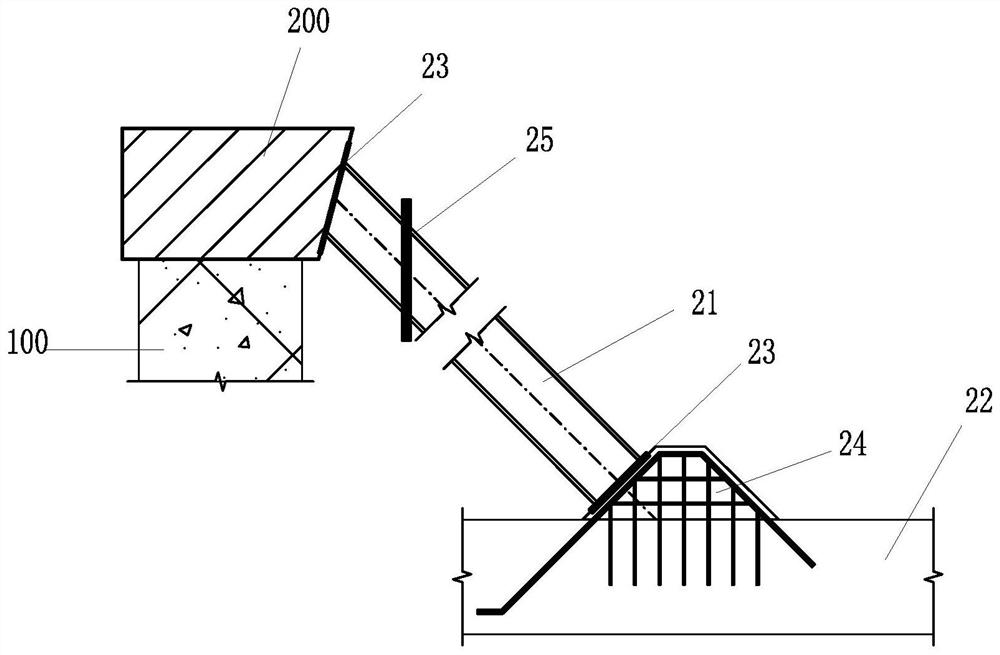

[0031] Please check figure 1 and figure 2 , a foundation pit oblique support system, which includes a side wall enclosure structure 100 of the foundation pit, a crown beam 200 connected to the side wall enclosure structure, steel pipe diagonal braces, and corbels; the corbels are fixed on the foundation pit floor, The steel pipe diagonal brace is between the side wall enclosure structure 100 and the foundation pit floor. One end of the steel pipe diagonal brace is fixedly connected to the crown beam 200 and the other end is fixedly connected to the corbel. Usually, a steel plate is pre-embedded on the corbel, and the steel pipe diagonal brace The support is fixedly connected with the corbel through the embedded steel plate.

[0032] For the steel pipe diagonal brace with a large support span, in order to prevent the steel pipe diagonal brace from being unstable due to excessive axial center pressure, a column 12 and a horizontal connecting rod are provided. One end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com