Efficient cooling method for turning and milling composite machine tool

A compound machine tool, turning and milling technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of broken mesh, easy to block pipes, easy to block filter screen with residue, etc., to achieve efficient cooling and high efficiency The effect of filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

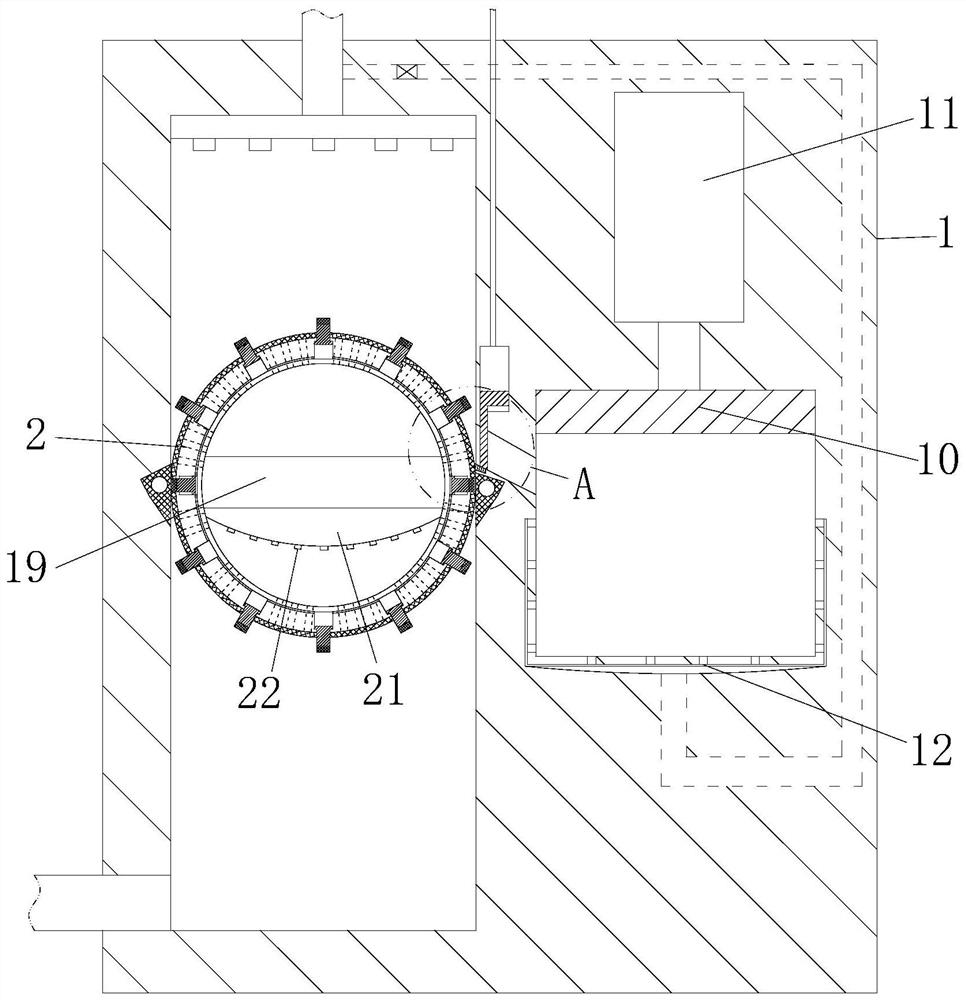

[0040] see Figure 2-6 As shown, the residue treatment box used in this high-efficiency cooling method includes a box body 1, a filter cartridge 2 and a motor 3; the inside of the box body 1 is provided with a processing chamber; the top of the processing chamber passes through the pipeline and the machine tool The residue liquid reflux hole is connected; the bottom of the processing chamber is connected with the cooling liquid nozzle through a pipeline; the inside of the processing box is connected with a filter cartridge 2 for rotation; the filter cartridge 2 includes a support tube 4 and a filter screen 5, and The filter screen 5 is sleeved on the outside of the support tube 4; the surface of the support tube 4 is provided with uniformly arranged through holes; the inner surface of the support tube 4 is fixedly connected with an internal gear ring 6 near the end surface of the support tube 4; The surface of the internal gear ring 6 is meshed with a gear 7; the inside of the...

Embodiment 2

[0049] see Figure 7 As shown, the inside of the rolling ball 25 is provided with a vibrating cavity; the inside of the vibrating cavity is provided with a vibrating ball 27; the elastic connecting rope 28 evenly arranged is firmly connected between the vibrating ball 27 and the inner surface of the vibrating cavity The inner surface of the vibration chamber is fixedly connected with the second bump 29 evenly arranged, and the second bump 29 is designed as an arc-shaped elastic metal sheet; during work, the vibration chamber is opened in the inside of the rolling ball 25 to vibrate Vibrating balls 27 are arranged inside the cavity. Since the vibrating balls 27 and the rolling balls 25 are connected by a uniform elastic rope 28, when the rolling balls 25 roll down, they will receive a greater impact, and the vibrating balls 27 can play a buffering role. , to reduce the impact and rebound of the rolling ball 25, and at the same time, when the rolling ball 25 and the vibrating ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com