A device and process method for treating oil fume tail gas

A technology for exhaust gas and oil fume, applied in separation methods, gas treatment, combined devices, etc., can solve the problems of electrostatic dust removal and oil removal, which are not resistant to high temperature, dirty filter cotton, and easy to be dirty and blocked. The effect of improved reliability and stability, large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

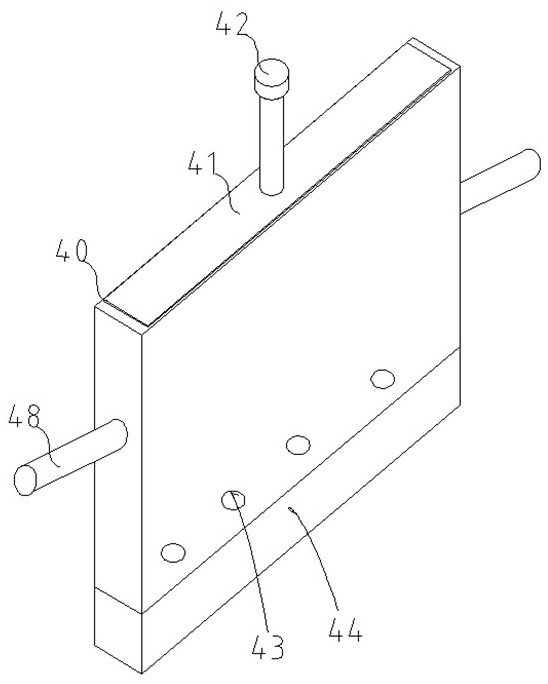

[0032] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

[0033]A device for treating oil fume tail gas, comprising a washing unit 34, an electrostatic unit 35 and a polishing unit 36, the washing unit 34 is connected to the electrostatic unit 35 through a pipeline 22, the electrostatic unit 35 is connected to the polishing unit 36 Connected through a filter channel 37, the washing unit 34 includes a flue gas inlet 1, the flue gas inlet 1 is connected to the upper end of the washing pipe 3 through a flue gas pipe 2, and a waste reducing device 38 is arranged in the washing pipe 3, The lower end of the washing pipe 3 is connected to the separation device 33, the separation device 33 includes a separation tower 11, the lower end of the separation tower 11 is connected to the liquid return pipe 10 of the waste reducing device 38, and the upper end of the separation tower 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com