Design of liquid filtering device and online sterilization and degerming method

A filter device and liquid technology, which is applied in the direction of mixing method, filtration separation, separation method, etc., can solve the problems of not considering the risk of filter element contamination, high filter efficiency, and inability to sterilize air, so as to avoid the increase of bacterial contamination coefficient , The operation is simple and clear, and the operation is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

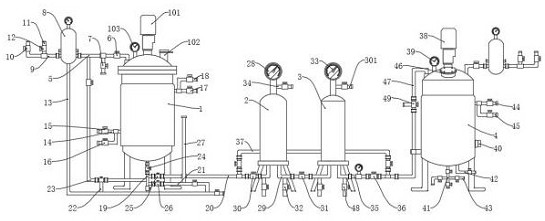

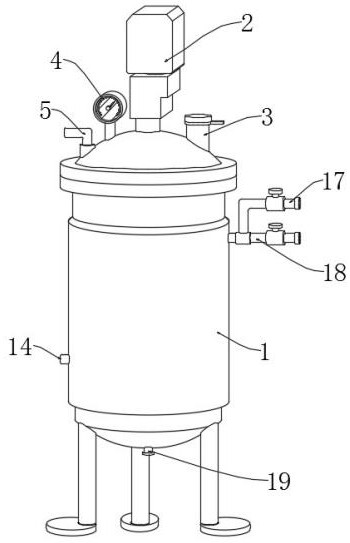

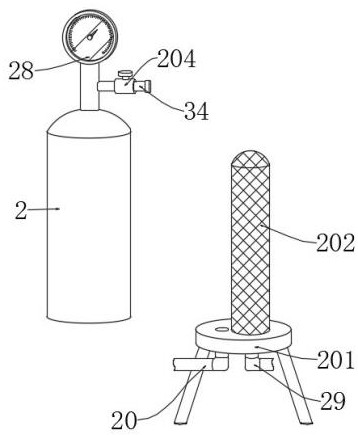

[0035] The present invention provides such Figure 1-5The design of a kind of liquid filtering device shown and the method for on-line sterilization and degerming include feeding tank 1, liquid coarse filter 2, liquid sterilizing filter 3 and reaction tank 4, it is characterized in that: described feeding A first mixer 101 is provided at the central axis of the top of the inner wall of the material tank 1, and a V4 pressure gauge 103 is provided on the side away from the hand hole 102 on the top of the feeding tank 1;

[0036] One side of the outer wall of the feeding tank 1 and the reaction tank 4 is provided with an air sterilizing filter 8, and the inside of the air sterilizing filter 8 is provided with a second filter element 801. One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com