Signal fuzzy control filter for wafer detection device

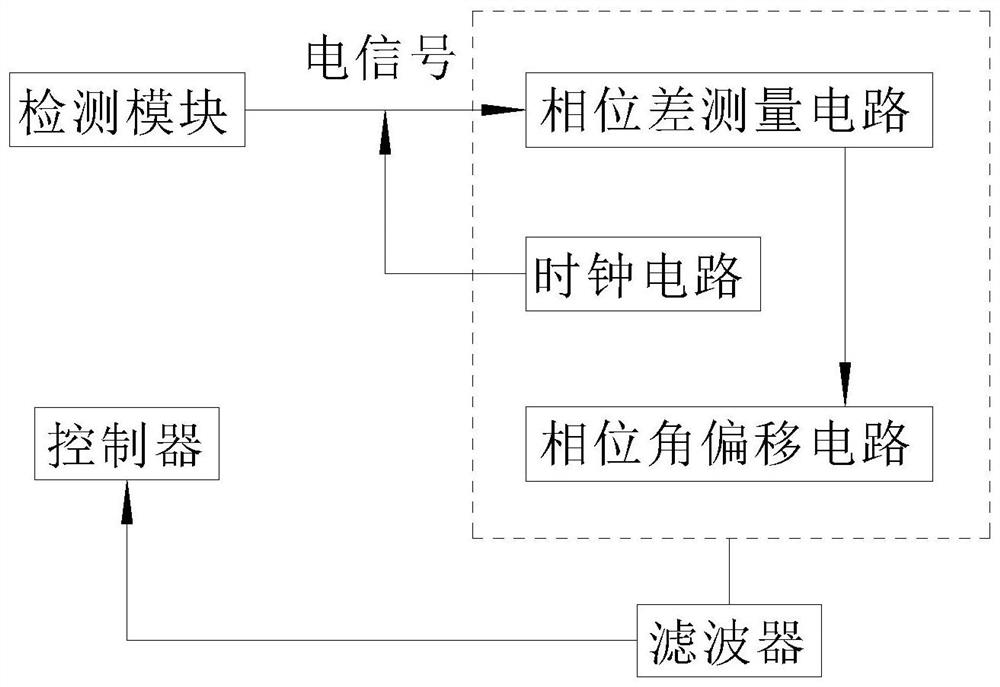

A detection device and fuzzy control technology, applied in the field of filters, can solve the problems of waveform detection accuracy interference, transmission accuracy interference, and unresolved problems, and achieve the effect of reducing the influence of temperature rise, avoiding temperature difference, and weakening interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

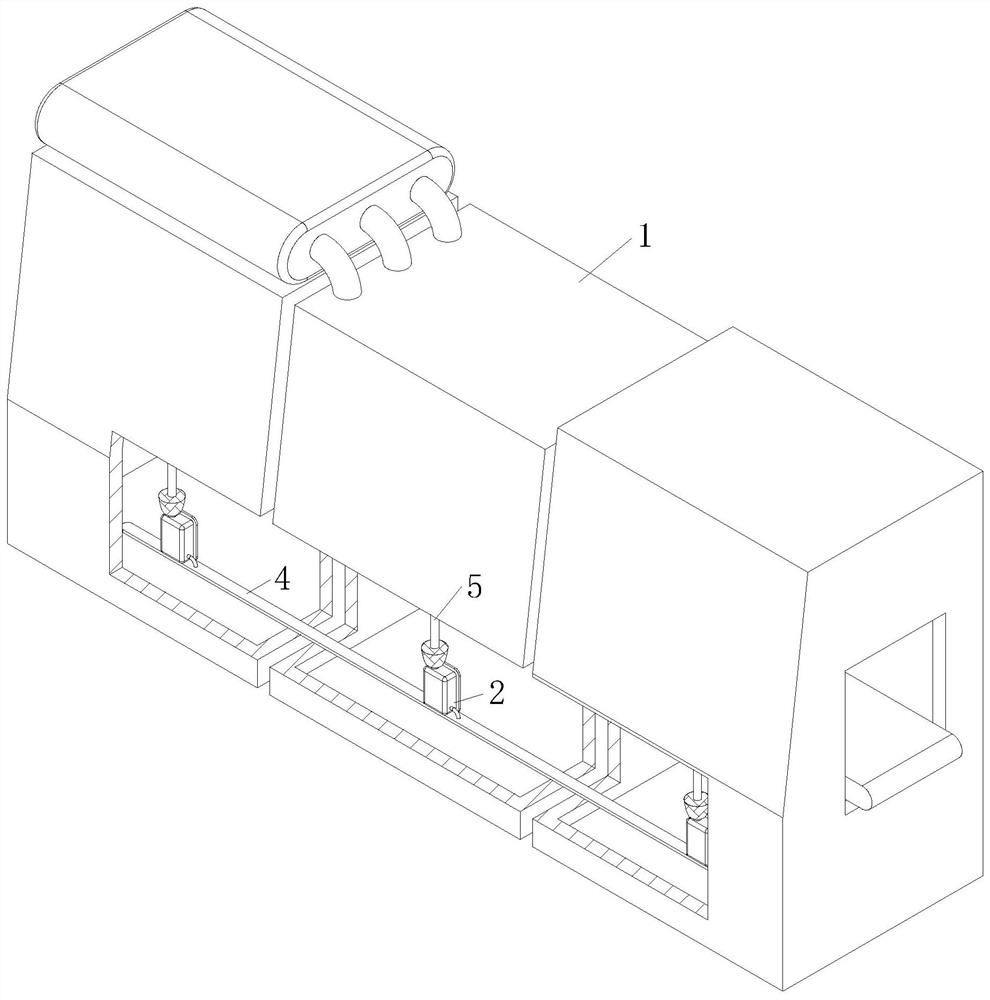

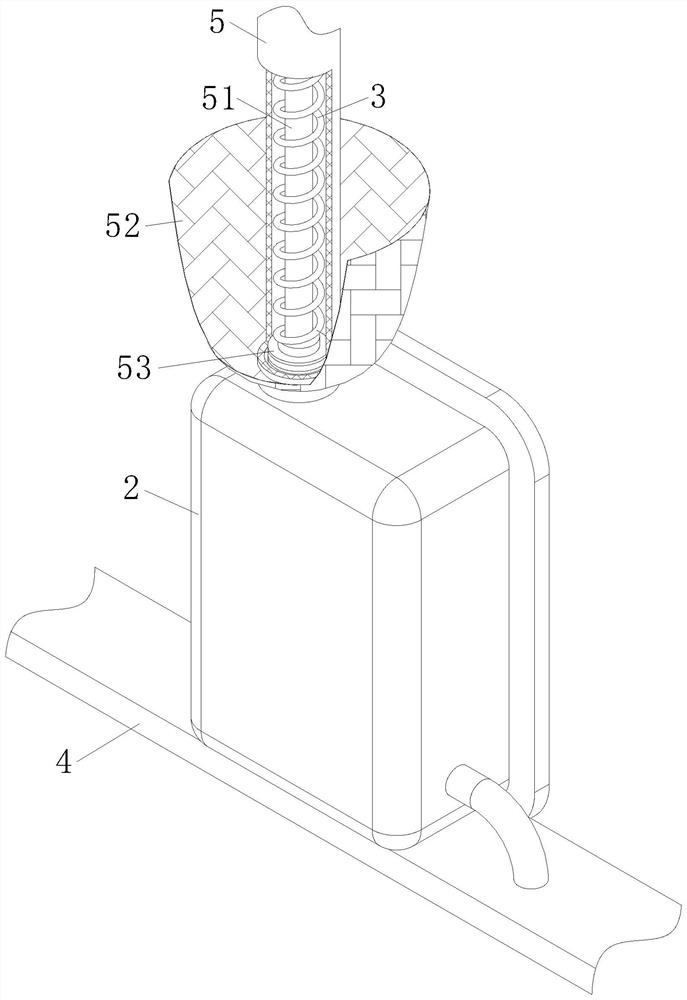

[0029] As an embodiment of the present invention, the wafer machine 1 is also provided with a protective cover 5 in each station, and the protective cover 5 is wrapped on the surface of the cable 3, the ground wire 4 and the filter terminal 2; The protective cover 5 is used to isolate the conduction of the processing temperature of the wafer machine 1; during operation, the wafer has different process parameters between different stations in the wafer machine 1; through the set protective cover 5, the filter terminal 2 and its electrically connected cable 3 and grounding wire 4 are wrapped on the surface to avoid the temperature difference of the wafer process parameters in different stations of the wafer machine 1, causing the filter terminal 2 and the cable 3 and the grounding wire 4 to be in the wafer The temperature difference between different stations of machine 1 leads to the difference in its circuit performance, and forms error accumulation and offset in the filter ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com