Heat dissipation type relay with breathing function

A breathing function, relay technology, applied in relay ventilation/cooling/heating, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of low thermal conductivity, unfavorable relay operation, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

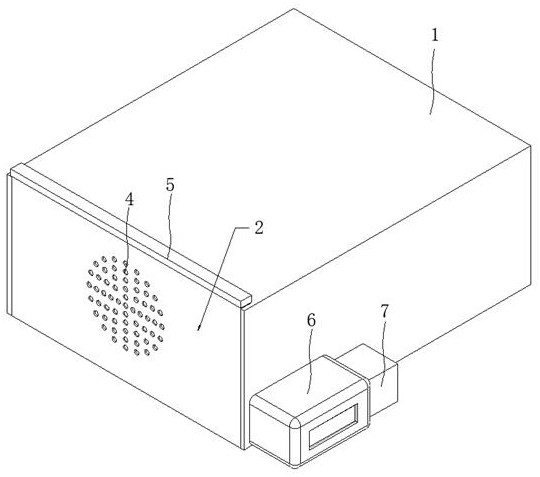

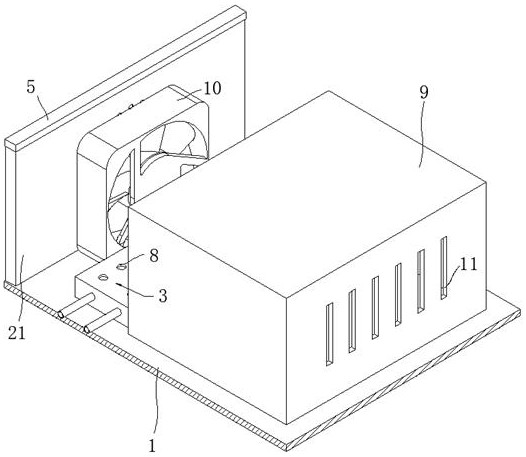

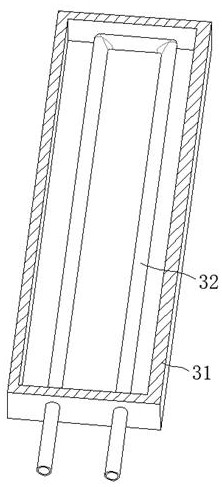

[0034] like Figure 1 to Figure 3 As shown, when the relay body 9 is working, the compressor 7 compresses the air and sends the compressed air into the U-shaped evaporating tube 32. At this time, the air temperature in the U-shaped evaporating tube 32 is relatively low, and the cooling box 31 and the protection box 1, the heat-absorbing air enters the condenser 6 from the output end of the U-shaped evaporating tube 32, and releases heat from the condenser 6, and then sends the air into the compressor 7 for compression, and repeats the process. Continuously reduce the temperature in the protection box 1, maintain the maximum average current on the relay body 9, and avoid the derating of the relay body 9 caused by the temperature of the relay body 9 being too high. melting deformation.

Embodiment 2

[0036] like figure 2As shown, a fan 10 is installed in the protection box 1, and the cold air produced by the cooling unit 3 flows into the protection box 1 from the through hole 8, and the cool air is blown to the relay body 9 by the fan 10, and at the same time, the relay body 9 phase Convection grooves 11 are provided on the side adjacent to the fan 10 and the side opposite to the fan 10 , and the air flow will send cold air into the relay body 9 to reduce the temperature in the relay body 9 .

Embodiment 3

[0038] like figure 1 and figure 2 As shown, a temperature sensor is installed in the protection box 1 to detect the temperature in the protection box 1. When the temperature is too high, the cooling unit 3 is activated to reduce the temperature of the relay body 9. When the temperature is low, the cooling unit 3 is turned off. , make the cooling unit 3 stop absorbing heat, make the temperature in the protection box 1 rise slowly, and keep the temperature in the protection box 1 within the operating temperature of the relay body 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com