Method for determining impurities in dalbavancin hydrochloride

A dalbavancin hydrochloride, quantitative dilution technology, applied in the field of pharmaceutical analysis, can solve problems such as residues, titration sensitivity and accuracy not meeting requirements, poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

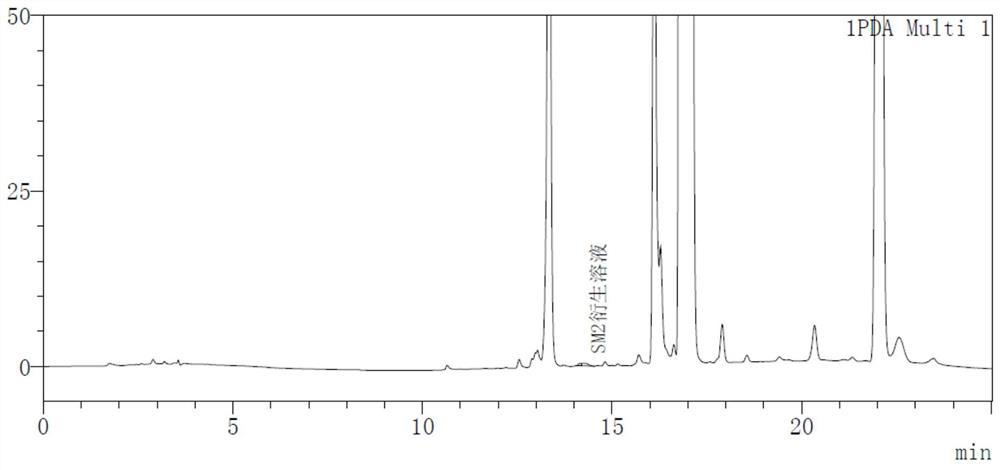

Image

Examples

Embodiment 1

[0045] High performance liquid chromatography: LC-2030C

[0046] Chromatographic column: Octadecylsilane bonded silica gel column (Ultimate ® C18, 4.6mm×250mm, 5 µm)

[0047] Mobile phase: 0.02mol / L sodium dihydrogen phosphate dihydrate aqueous solution is mobile phase A; acetonitrile is mobile phase B

[0048] The elution procedure of mobile phase A and B is:

[0049] time (min) Mobile phase A (%) Mobile phase B (%) 0 90 10 5 85 15 15 20 80 20 20 80 21 90 10 25 90 10

[0050] Flow rate: 1.0ml / min

[0051] Wavelength: 210nm

[0052] Injection volume: 50ul

[0053] Column temperature: 40°C

[0054] Implementation steps:

[0055] Boric acid-borax buffer: 0.05mol / L borax aqueous solution-0.2mol / L boric acid aqueous solution = 55:45 (v / v) Derivative reagent: 5mg / ml fluorenylmethoxycarbonyl chloride acetonitrile solution

[0056] Control solution: Accurately weigh about 50 mg of 3-dimethylaminopropylamine in a 10ml measur...

Embodiment 2

[0061] High performance liquid chromatography: Agilent1260

[0062] Derivatization reagent: 2.5mg / ml benzoyl chloride acetonitrile solution;

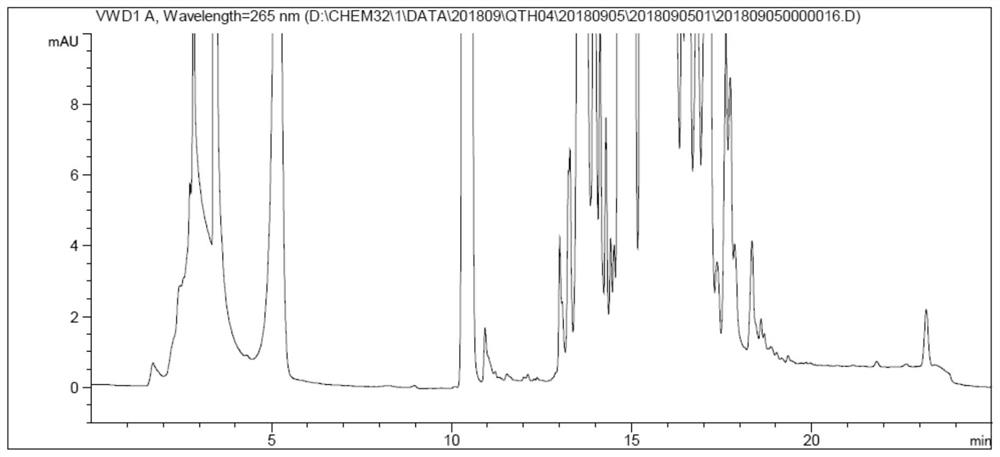

[0063] All the other conditions are with embodiment 1;

[0064] Implementation steps:

[0065] Take each 50 μl of the blank, the reference substance and the derivative solution of the test substance and inject them into the liquid chromatograph, and record the chromatograms. see attached results figure 2 .

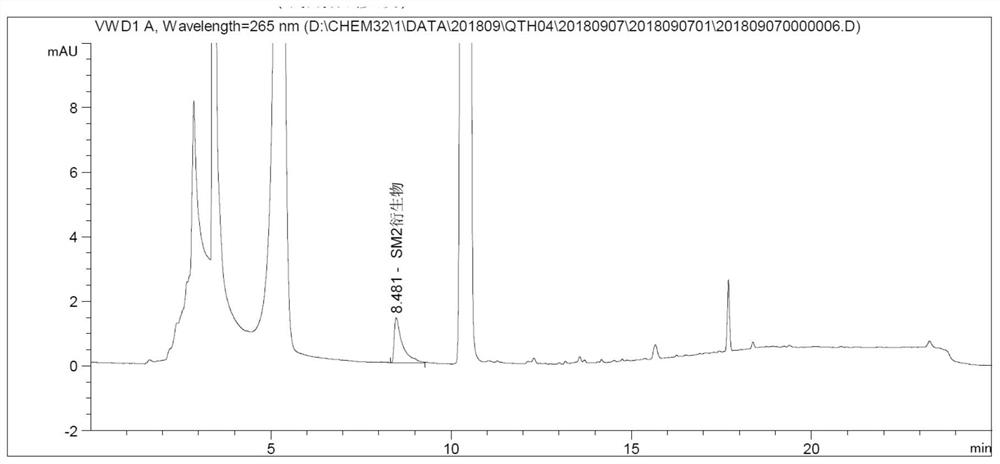

Embodiment 3

[0067] High performance liquid chromatography: Agilent 1260

[0068] Chromatographic column: Octadecylsilane bonded silica gel column (Ultimate ® C18, 4.6mm×250mm, 5 µm) Mobile phase: 0.02mol / L aqueous solution of sodium dihydrogen phosphate dihydrate as mobile phase A; acetonitrile as mobile phase B. The elution procedure of mobile phase A and B is:

[0069] time (min) Mobile phase A (%) Mobile phase B (%) 0 90 10 5 85 15 15 20 80 20 20 80 21 90 10 25 90 10

[0070] Flow rate: 1.0ml / min

[0071] Wavelength: 265nm

[0072] Injection volume: 50ul

[0073] Column temperature: 40°C

[0074] Implementation steps:

[0075] Boric acid-borax buffer solution: 0.05mol / L borax aqueous solution-0.2mol / L boric acid aqueous solution=55:45 (v / v)

[0076] Derivatization reagent: 2.5mg / ml benzoyl chloride acetonitrile solution

[0077] Control solution: Accurately weigh about 50 mg of 3-dimethylaminopropylamine in a 10ml measuring b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

| Column inner diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com