Temperature testing device used in cooperation with temporary plugging agent

A technology of testing device and temporary plugging agent, applied in wellbore/well components, earthwork drilling, construction, etc., can solve the problems of cumbersome plugging work and increase plugging costs, etc., and achieve convenient fracturing plugging and reduce The cost of blocking, the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

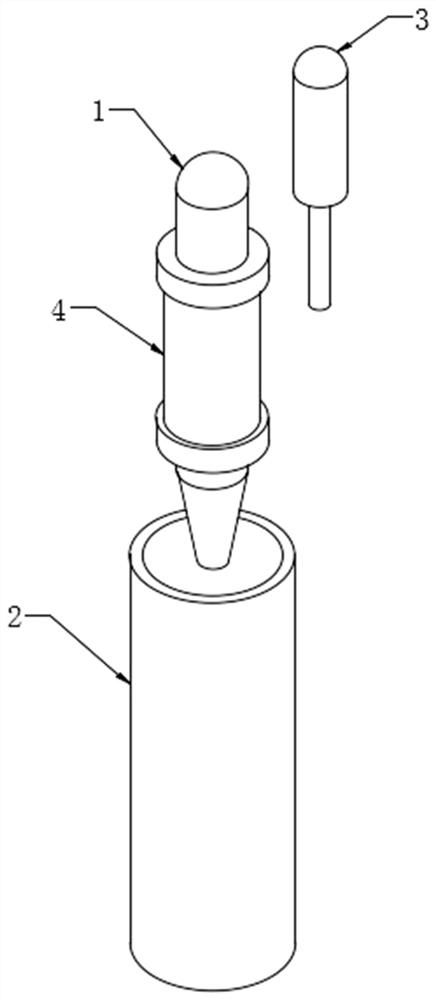

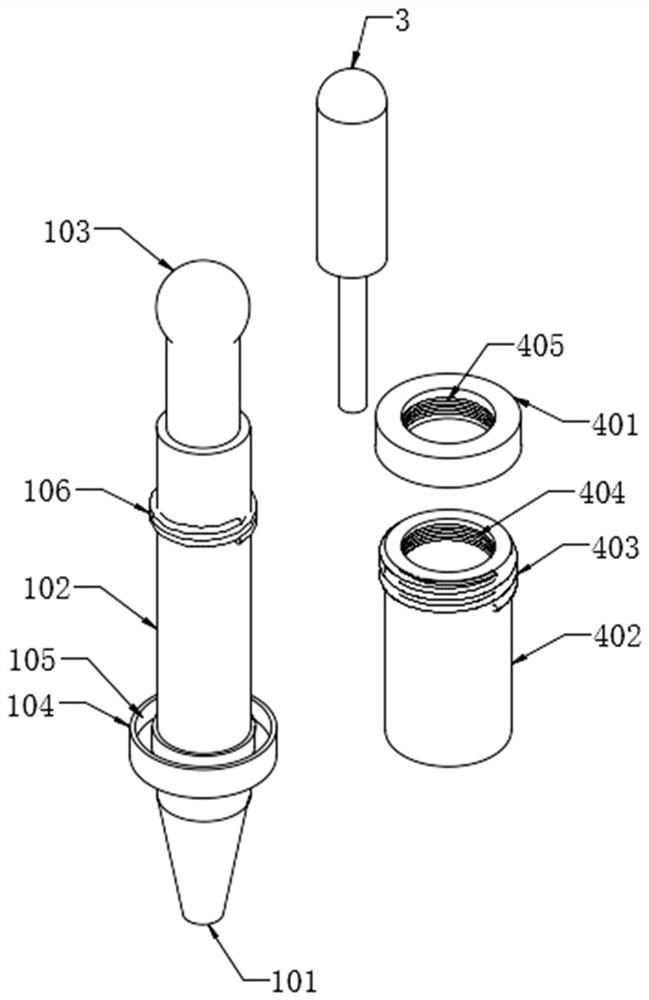

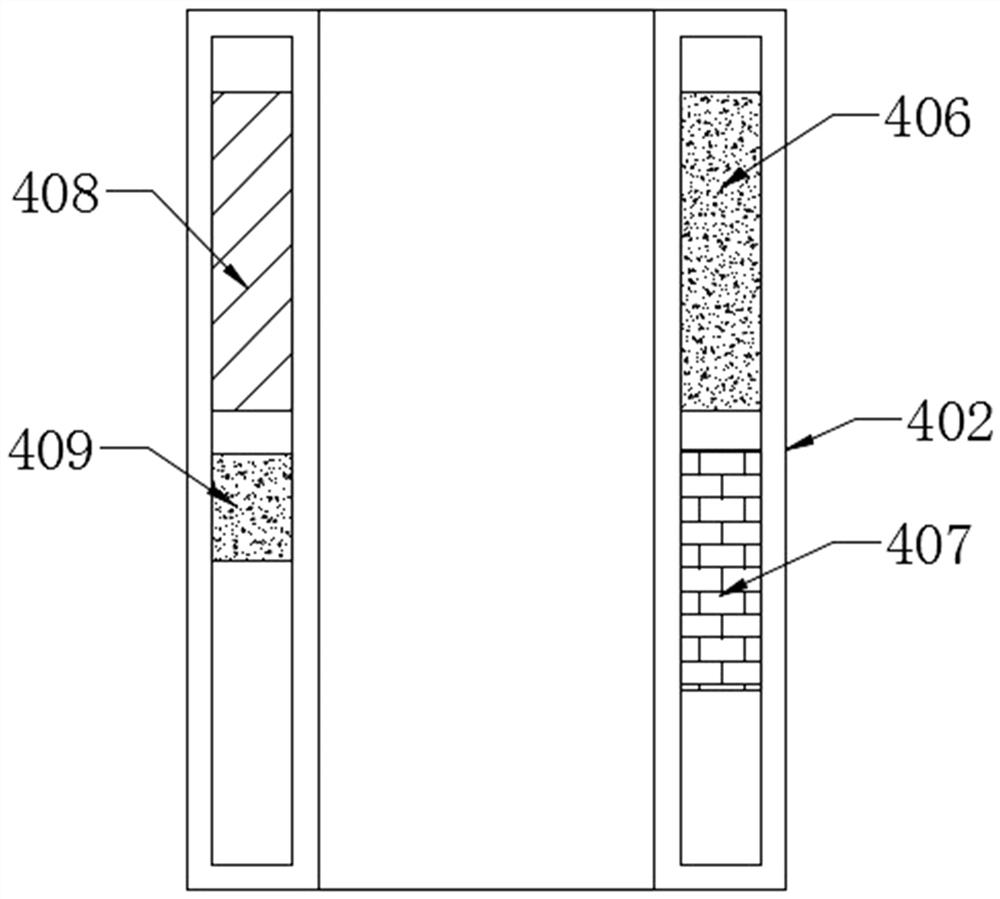

[0028] Embodiment 1: When the device is in use, the setting bridge plug mechanism 1 is first assembled, and after the assembly is completed, the protective shell 402 in the temperature measuring mechanism 4 is set on the outer casing 102 of the setting bridge plug mechanism 1 The circumferential side wall then rotates the protective shell 402, so that the first threaded groove 404 inside the protective shell 402 rotates and moves downward in the first thread 106, and then the bottom end of the protective shell 402 is clamped inside the thread limiting groove 105, And the protective shell 402 is limited by the limit block 104 to prevent the protective shell 402 from moving downward. At the same time, the threaded fixed cover 401 is connected to the protective shell 402 through the housing 102, and the threaded fixed cover 401 is rotated so that the screw thread is fixed. The cover 401 rotates on the first thread 106 on the side wall of the housing 102, so that the top of the pro...

Embodiment 2

[0030] Embodiment 2: At the same time, the top of the protective shell 402 can be installed downwards, so that the second thread 403 is threadedly connected with the thread limiting groove 105, and then the second thread 405 and the first thread 106 inside the screw fixing cover 401 are connected The threaded fixing cover 401 is installed on the side wall of the casing 102, so as to limit the bottom end of the protective casing 402, and then the measurement can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com