Deep imbedded underground water-permeable passage plugging method

A channel and downstream technology, which is applied in the field of underground water permeable channel plugging and treatment, can solve the problems of underground engineering or mine facilities scrapping life and property, damage and loss of engineering facilities, etc., to reduce the workload of plugging, reduce the cost of plugging, targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

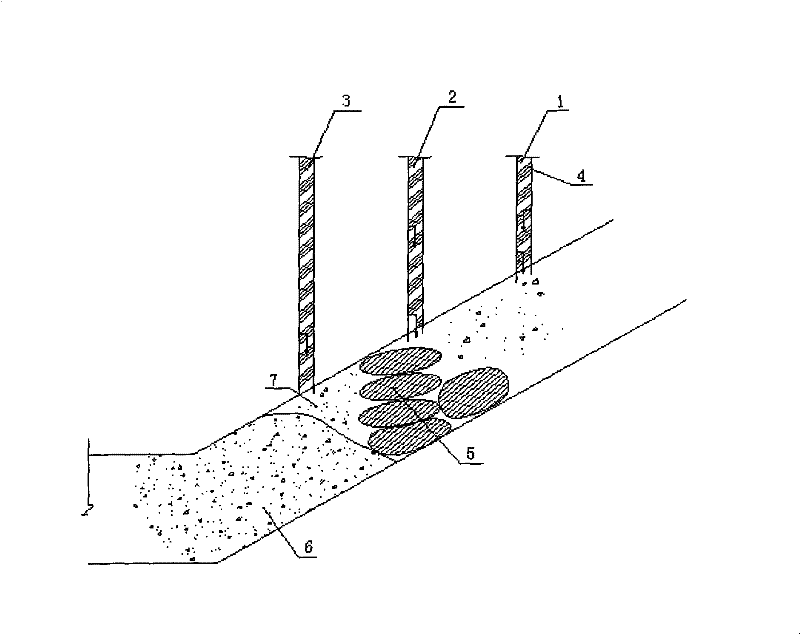

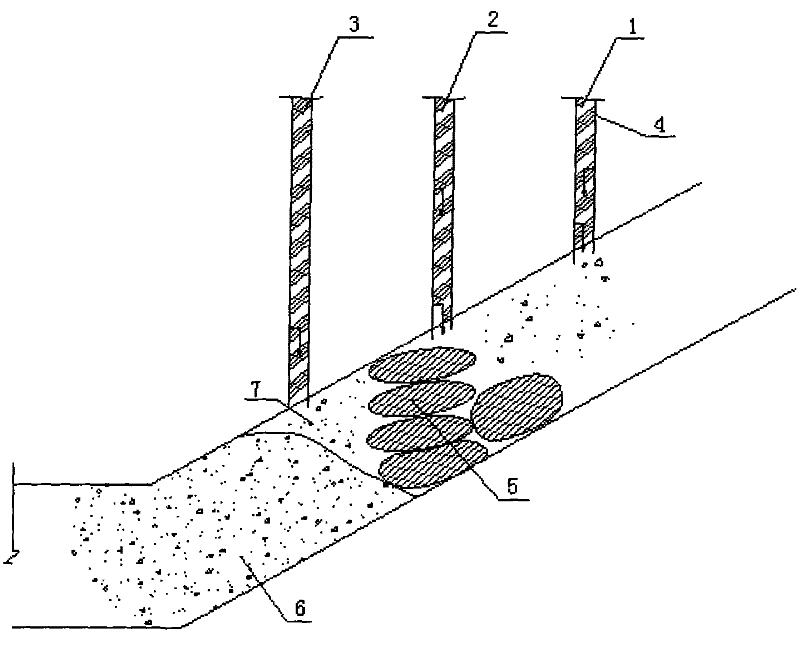

[0021] Through measurement, the flow velocity at the dew point of the main permeable channel is 0.5m / s, and the flow rate is 2.5m 3 / s;

[0022] Drill three plugging holes in the permeable channel, i.e., upstream hole 1, midstream hole 2 and downstream hole 3, with a diameter of 100 mm and a hole depth of 80 m. Add wall protection steel sleeve 4 in the interior.

[0023] Choose stones with a particle size of 15-25 mm,

[0024] In the upstream hole 1, use high-pressure wind to blow and throw the blocking stone into the hole;

[0025] In the midstream hole 2, the high-pressure wind direction is used to block the mold bag concrete, and the mold bag concrete 5 is ordinary concrete with ordinary grades packed in woven bags;

[0026] In the downstream hole 3, the betting stone is blocked with high-pressure air to form the betting stone area 6;

[0027] After the water seepage at the leakage point is significantly reduced, grout the upstream hole 1 and the middle hole 2 until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com