A leak detection and plugging assembly and plugging method for an oil passage hole of a tractor gearbox body

A gearbox body and leakage detection technology, which is applied to engine components, engine sealing, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of non-universal, low work efficiency, high cost, etc., to improve work efficiency , Reduce the cost of plugging, and solve the effect of plugging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

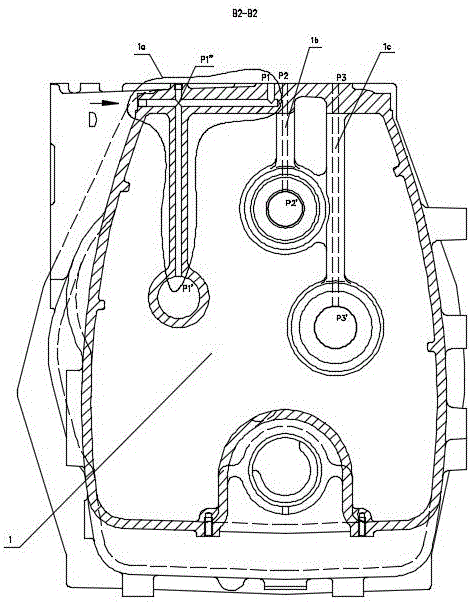

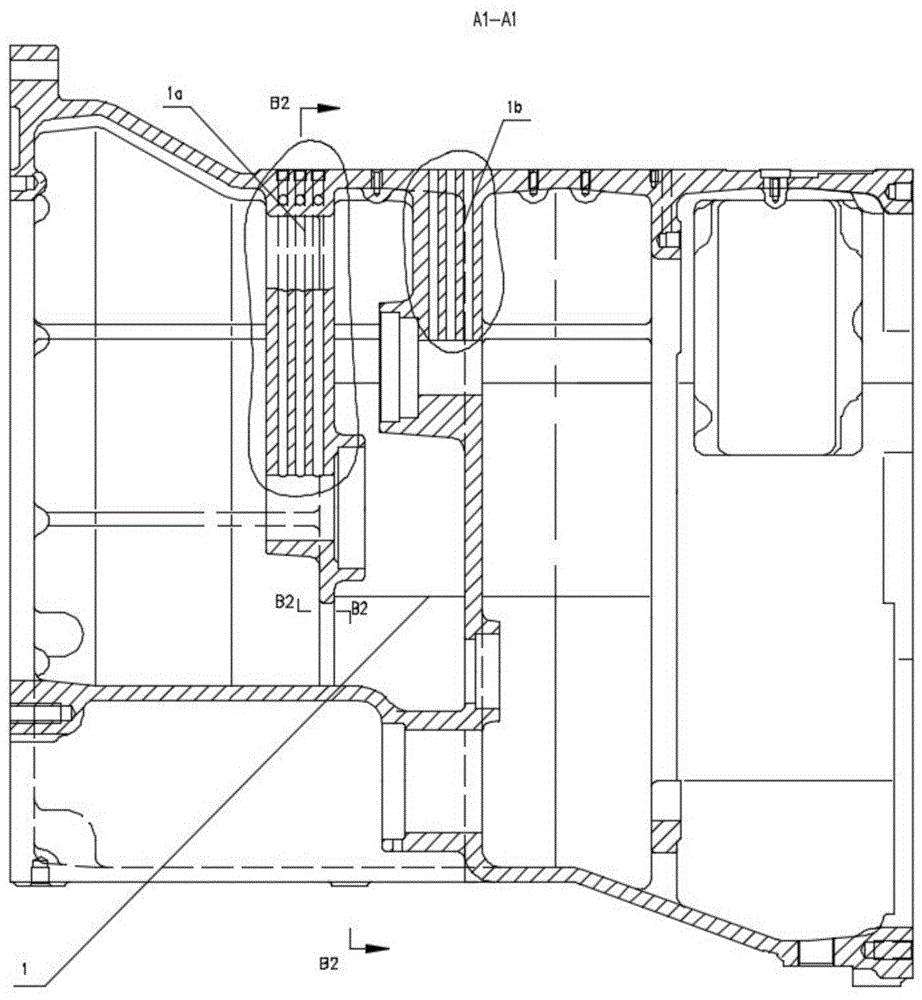

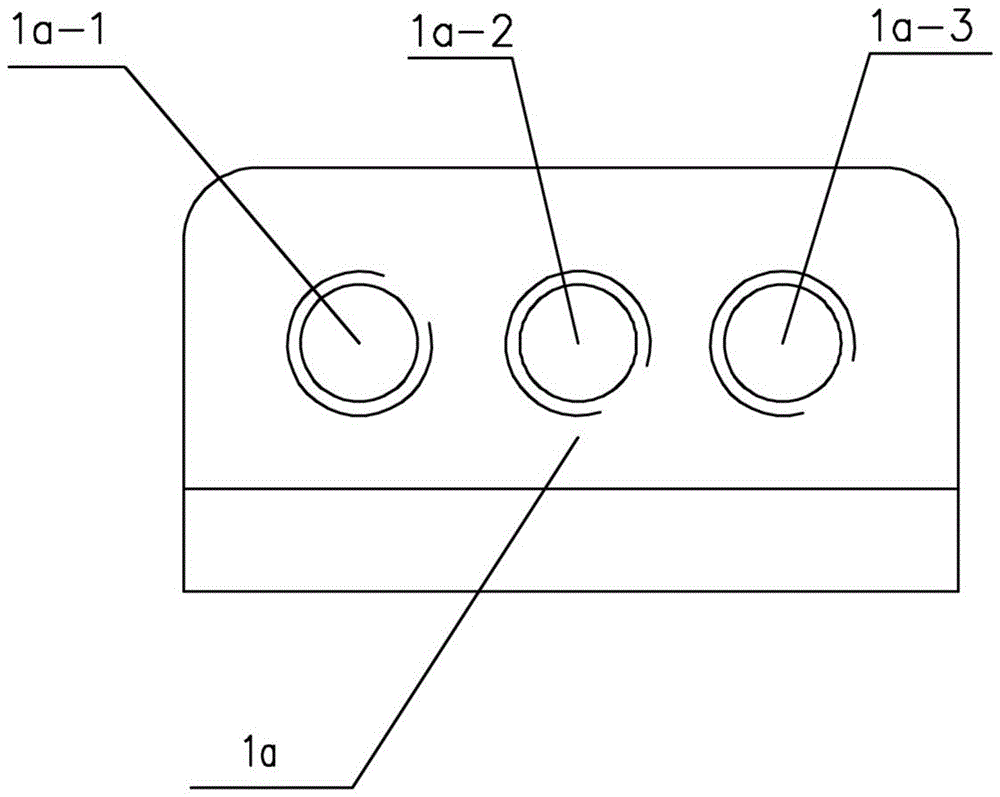

[0050] The present invention can be explained in more detail through the following examples, a tractor gearbox body oil passage hole leakage detection plugging assembly and plugging method, used for power shift tractor gearbox body leakage detection device, power shift tractor gear shift The detected holes of the box are 3 groups of 9 holes. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0051] Depend on Figure 5 Known, a kind of tractor gearbox body oil passage hole leakage detection plugging assembly, comprises plugging panel fitting 2, screw hole blocking block fitting 3 and internal expansion plugging head fitting 4, and described plugging panel fitting 2 is fixed It is arranged on the upper part of the gearbox body 1, and the upper part of the plugging panel assembly 2 is connected with the combined valve block assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com