Low-cost solar film reflector material

A technology of solar thin film and reflector, which is applied in the field of solar energy utilization, can solve the problems of large fossil energy consumption and high cost, and achieve the effect of reducing manufacturing cost and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

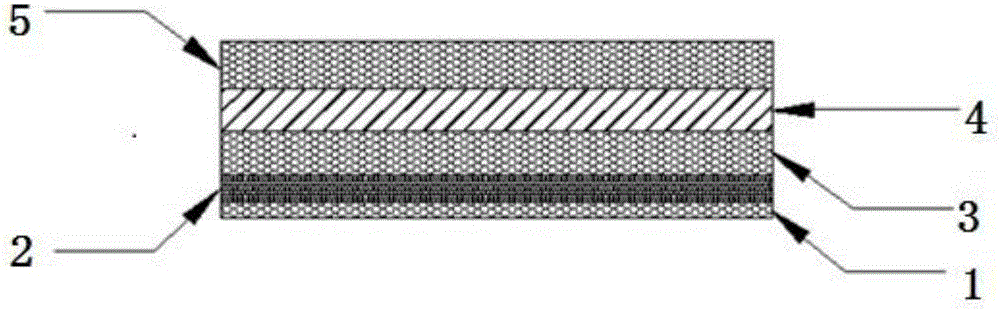

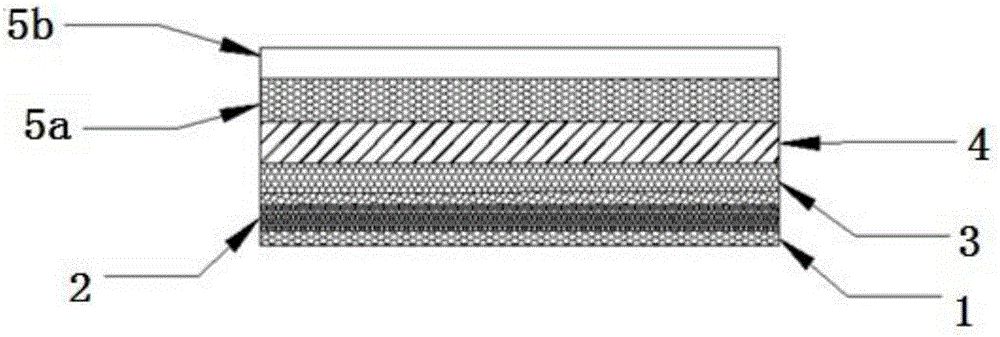

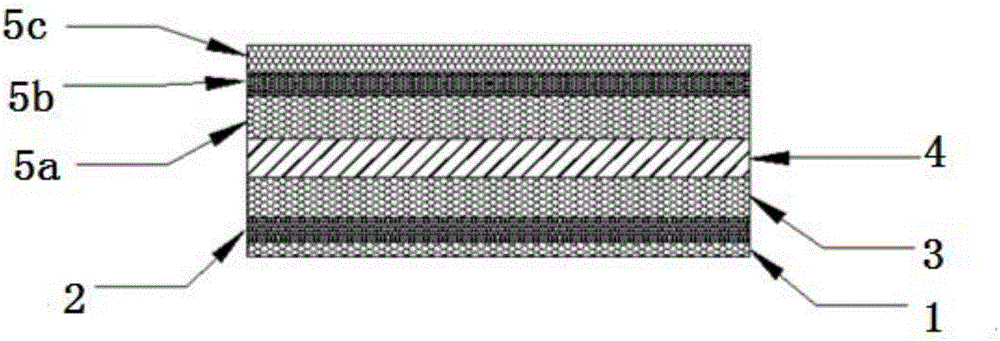

[0042] The following examples are combined with the attached Figure 4-5 way to further describe the present invention.

[0043] Such as Figure 4 to Figure 5 Shown, it has shown the specific composition of solar thin-film reflector material of the present invention, and solar thin-film reflector material comprises back glue protection film 1, back glue 2, substrate film 3, coated film reflective layer and coated film protective layer, wherein the back Adhesive protective film 1 is pasted on the lower surface of back glue 2, and substrate film 3 is formed on the upper surface of back glue 2, and coated film reflective layer is formed on the upper surface of substrate film 3, and coated film protective layer is formed on this coated film reflective layer surface. The back glue 2 is made of acrylic pressure-sensitive adhesive, the base film 3 is made of PET film, the lower surface 3a of the base film 3 is sensitized so as to be firmly combined with the back glue 2, and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com