A sealing structure for diversion tunnel

A technology of diversion tunnels and diversion tunnels, applied in water conservancy projects, hydroelectric power stations, hydroelectric power generation, etc., can solve problems such as hidden safety hazards, large construction pressure, and large amount of blocking, so as to save blocking costs and improve sealing. The effect of blocking effect and reducing the workload of plugging construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

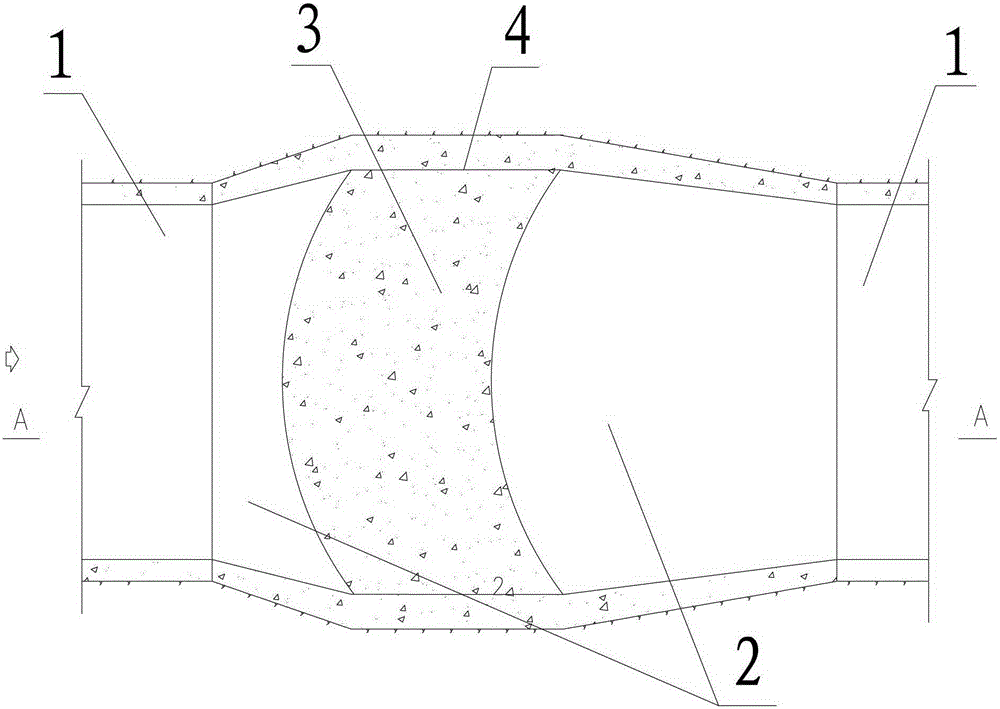

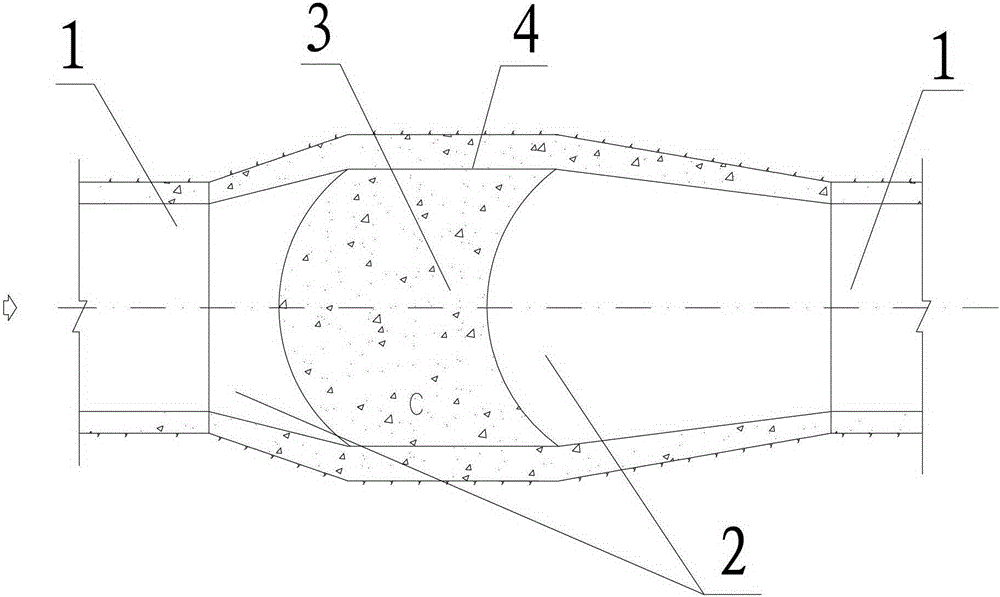

[0014] Such as figure 1 , figure 2 Shown is a plugging structure for diversion tunnels with a small amount of plugging construction work and good plugging effect provided by the present invention. The sealing structure includes a diversion tunnel 1 arranged in the concealed body and a sealing body located in the diversion tunnel 1, and a section of the diversion tunnel 1 is provided with a longitudinal section that is small at both ends and large in the middle. An olive-shaped plugging section 2, the plugging body is an olive-shaped plugging body 3 adapted to the shape of the olive-like plugging section 2, and the olive-shaped plugging body 3 is located in the olive-like plugging body The position of the largest cross-section of the type plugging section 2. In the above, a section of olive-shaped sealing section 2 with small ends and a large middle in the longitudinal section is set on the diversion tunnel 1, and the sealing body is set to be similar in shape to the olive-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com