Polymer for crude oil pour point depressing and preparation method and application thereof

A technology of crude oil point depressant and crude oil point depressant, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of single chemical bond, limited effect of point point depressant, poor effect of point point depressant, etc., and achieve simple process, It is conducive to the promotion and use of industrialization, and is convenient for mining and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of crude oil pour point depressant, specifically comprising the following steps:

[0037] (1) Preparation of polymer:

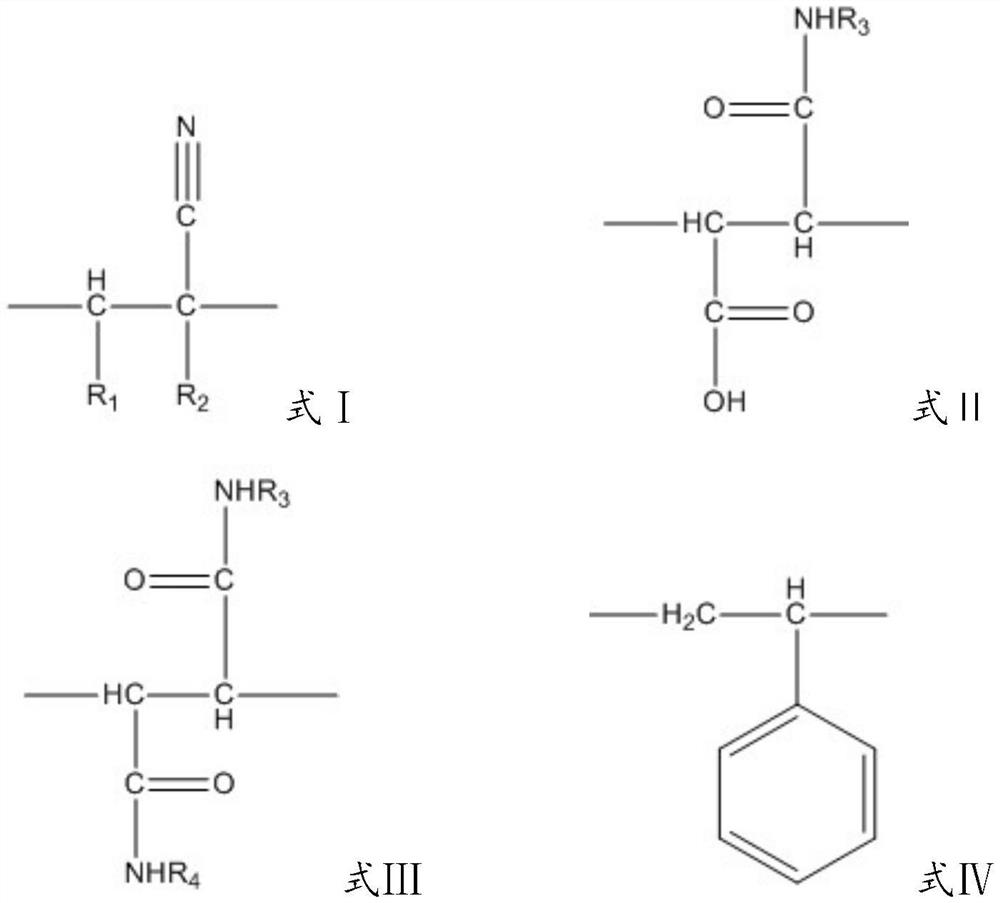

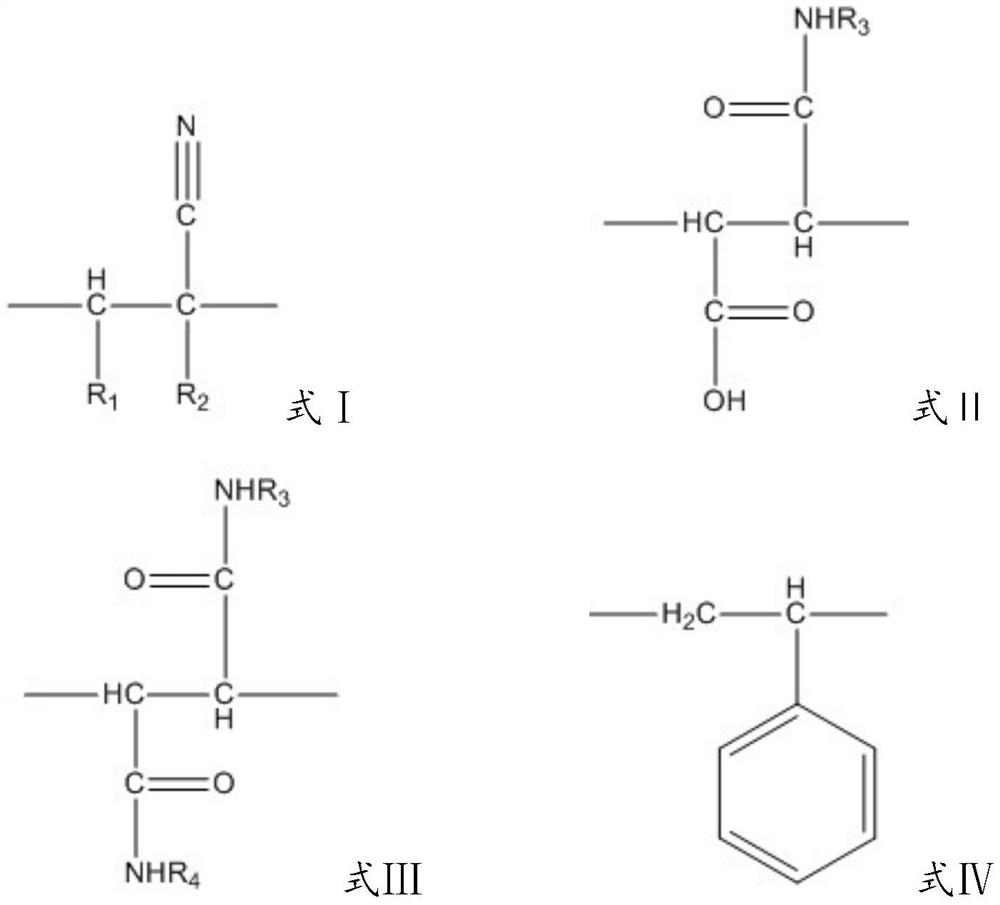

[0038] 1) Add monomers acrylonitrile, fumaric acid and styrene with a molar ratio of 2:15:3 to xylene, which is half of the total mass of the monomers, keep stirring at 80°C for 30 minutes, and add benzoyl peroxide , reacted for 6h, and the consumption of benzoyl peroxide was 1% of the total mass of the monomers to obtain a terpolymer;

[0039] 2) Mix the above-mentioned terpolymer with a molar ratio of 1:2 and C18 fatty primary amine, carry out amidation reaction at a temperature of 115°C, react for 3h, heat up to 155°C for 1h, and obtain a terpolymer ( In formula Ⅰ, R 1 for H, R 2 is H; in formula III, R 3 is C18 alkyl, R 4 C18 alkyl), the molecular weight of the polymer is 3000-5000;

[0040] (2) Preparation of synergist:

[0041]Add oleic acid glyceride dropwise to methyl-terminated allyl polyether, the mass ratio of met...

Embodiment 2

[0044] A preparation method of crude oil pour point depressant, specifically comprising the following steps:

[0045] (1) Preparation of polymer:

[0046] 1) Add the monomers acrylonitrile, fumaric acid and styrene with a molar ratio of 2:15:3 to toluene, which is half of the total mass of the monomers, keep stirring at 80°C for 30 minutes, and then add tert-butyl hydroperoxide , reacted for 6h, and the consumption of tert-butyl hydroperoxide was 0.5% of the total mass of the monomers to obtain a terpolymer;

[0047] 2) Mix the above-mentioned terpolymer with a molar ratio of 1:2 and C18 fatty primary amine, carry out amidation reaction at a temperature of 115°C, react for 3h, heat up to 155°C for 1h, and obtain a terpolymer ( In formula Ⅰ, R 1 for H, R 2 is H; in formula III, R 3 is C18 alkyl, R 4 C18 alkyl), the molecular weight of the polymer is 3000-5000;

[0048] (2) Preparation of synergist:

[0049] Add oleic acid glyceride dropwise to methyl-terminated allyl pol...

Embodiment 3

[0052] A preparation method of crude oil pour point depressant, specifically comprising the following steps:

[0053] (1) Preparation of polymer:

[0054] 1) Add monomers methacrylonitrile, fumaric acid and styrene with a molar ratio of 3:13:4 to xylene with a total monomer mass of 2 / 3, keep stirring at 75°C for 40 minutes, add iso Propylbenzene hydroperoxide, reaction 7h, the consumption of cumene hydroperoxide is 2% of monomer gross mass, makes terpolymer;

[0055] 2) Mix the above-mentioned terpolymer with a molar ratio of 1:1.2 and C20 fatty primary amine, carry out amidation reaction at a temperature of 105°C, react for 4 hours, heat up to 150°C and dehydrate for 1.5h to obtain a terpolymer (In Formula I, R 1 for H, R 2 Is C1 alkyl; in formula II or formula III, R 3 is C20 alkyl, R 4 is C20 alkyl), the molecular weight of the polymer is 3000-5000;

[0056] (2) Preparation of synergist:

[0057] Add oleic acid glyceride dropwise to butyl-terminated allyl polyether, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com