Brake pad support following anti-eccentric-wear mechanism and brake device with same

A technology of brake device and brake pad holder, applied in brake wear compensation mechanism, railway braking system, transportation and packaging, etc., can solve the problem of eccentric wear of brake pads and brake discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

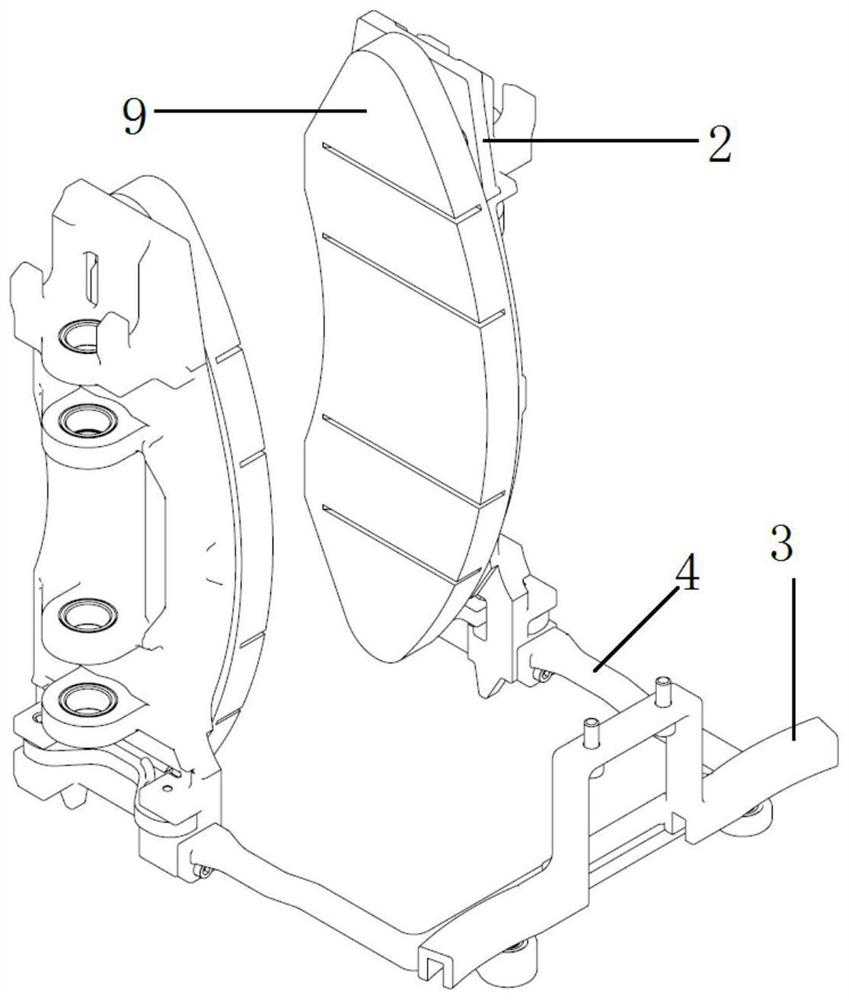

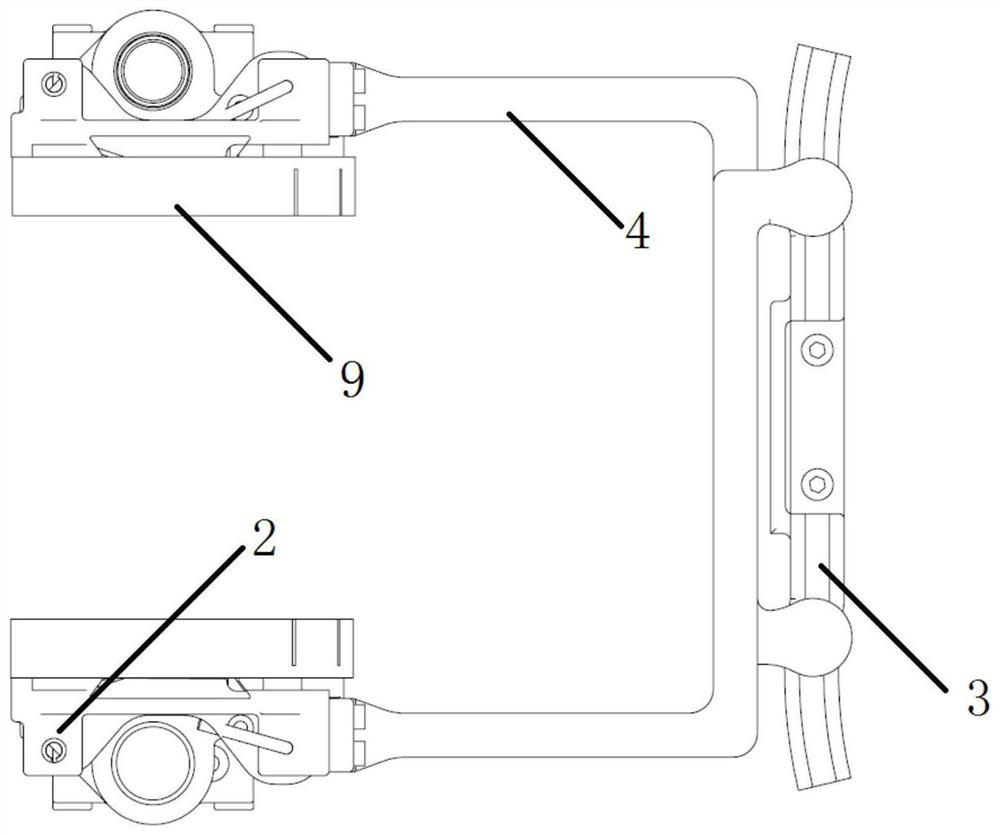

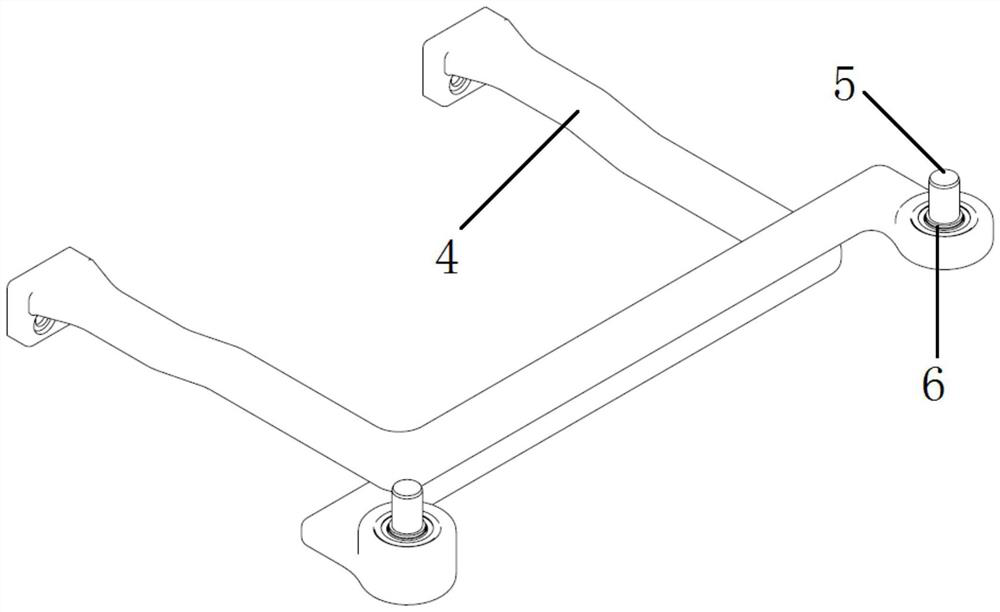

[0036] Such as Figure 1 to Figure 6 As mentioned above, a brake pad holder provided in this embodiment follows the anti-eccentric wear mechanism and is installed between the hanger 1 and a pair of brake pad holders 2, and the pair of brake pad holders 2 are symmetrically installed on both sides of the hanger 1. It includes: a slide rail 3 installed on a hanger 1 and a pair of pull rod bodies 4 .

[0037] A pair of tie rod bodies 4 are arranged crosswise, and the tie rod bodies 4 are installed in one-to-one correspondence with the brake pad holder 2. One end of the tie rod body 4 is fixedly installed on the brake pad holder 2, and the other end is vertically installed with a rotating shaft 5, and the rotating shaft 5 is slidably installed on the slide rail 3 Inside and rotatably matched with the slide rail 3, a pair of tie rod bodies 4 are Z-shaped three-section rods, and the middle sections of a pair of tie rod bodies 4 are arranged parallel to each other and abutted against ...

Embodiment 2

[0042] This embodiment provides a braking device, the braking device provided in this embodiment is a brake caliper, which has the anti-eccentric wear mechanism described in Embodiment 1 for the brake pad support. Also includes: a hanger 1, a brake cylinder and a pair of brake pad holders 2.

[0043] The lower side of the hanger 1 is equipped with an intermediate support frame 7, and a pair of brake levers 8 are symmetrically installed on the left and right sides of the intermediate support frame 7, and the brake lever 8 and the intermediate support frame 7 are rotated and matched; At the end of each brake lever 8, a pair of brake pad holders 2 are equipped with a brake pad body 9 on the opposite side. Both ends of the brake cylinder are respectively fixedly connected to one side of a pair of brake levers 8 and one side of the brake pad holder 2 . The brake pad holder follows the guide rail of the anti-eccentric wear mechanism and is installed on the lower side of the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com