Eyelass frame, eyeglass, and method of manufacturing eyeglass frame

A spectacle frame and spectacle frame technology, applied in the field of spectacle frames, can solve the problems of complex manufacturing and assembly, wear of hinge shafts, etc., and achieve the effect of simple manufacturing and assembly methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

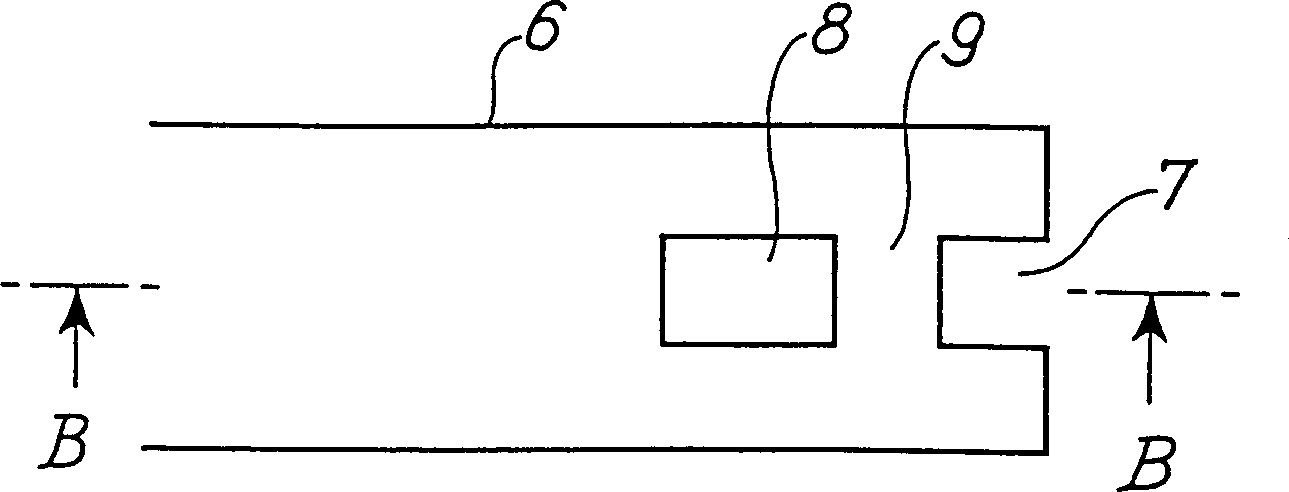

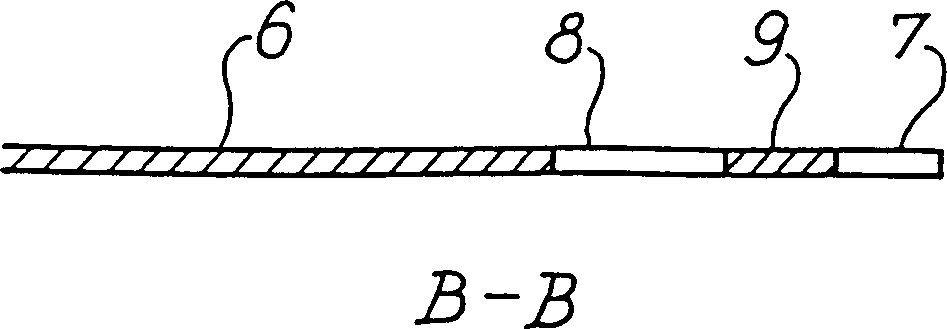

[0023] All drawings are diagrammatic and not necessarily to scale, showing only essential details for understanding the invention, while other details are omitted. Throughout the drawings, the same reference numerals designate the same or similar components.

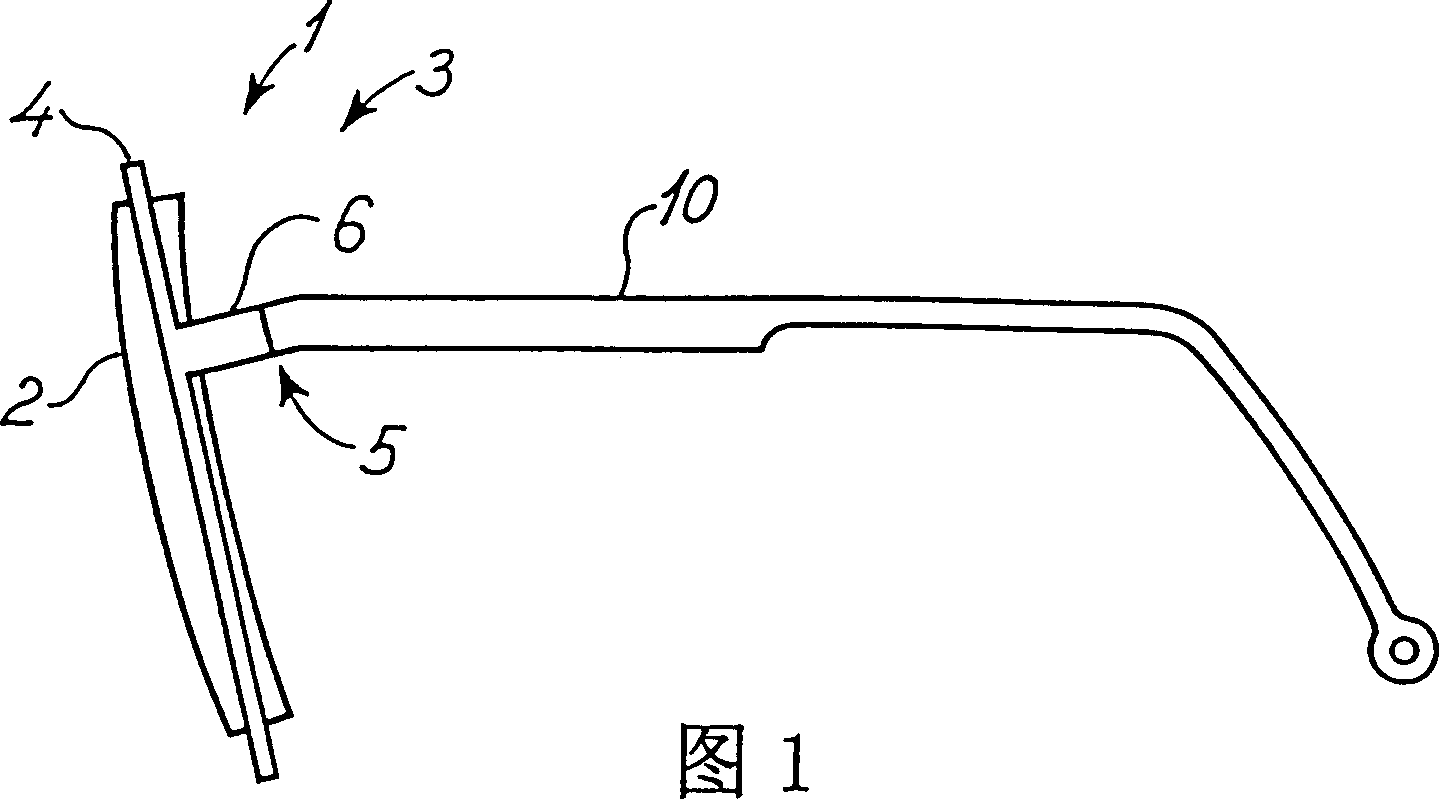

[0024] Referring now to Fig. 1, it overall shows the side view of glasses of the present invention, and this glasses 1 mainly comprises spectacle frame 3, and spectacle frame 3 comprises the front part 4 that fixes two lenses 2, and two legs 10 are connected to front by corresponding hinge. Part 4 on. The two lateral ends of the frame front 4 where the hinge 5 is fixed are referred to as front pieces 6 .

[0025] figure 2 first part of Figure 2a The middle indicates the area near the end of the front piece before the frame is assembled. exist figure 2 In the preferred embodiment, the sheet consists of a strip of metal plate with parallel sides, apexed by a transversely cut end, the end region comprising an opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com