Rotary turbulent tube energy-saving water cooling device

A technology for water cooling and turbulent flow tubes, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as shortening service life, turbulent tube wear, and quality reduction, and achieves improved use efficiency, improved yield, Even cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

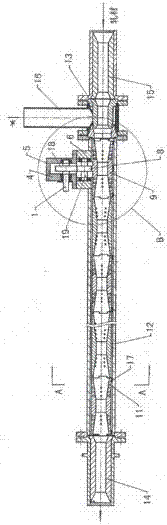

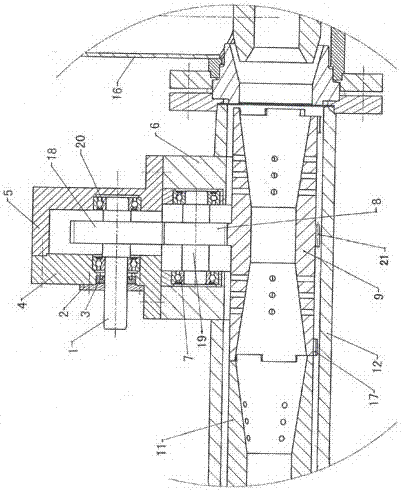

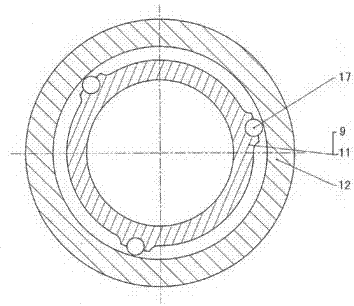

[0015] As shown in the drawings, a rotary turbulent tube energy-saving water-through cooling device according to the present invention includes a driving gear rotating shaft 1, a shaft end cover 2, a rotating shaft Y-shaped sealing ring 3, a driving gear box front cover 4, a driving Gear box 5, driven gear box 6, first bearing 7 (also called driven gear box bearing 7), driven gear 8, driving liner 9, driven liner 11, liner support tube 12, nozzle Seat 13, rolled material tail pipe 14, rolled material inlet pipe 15, water inlet pipe 16, needle roller 17, driving gear 18, driven gear rotating shaft 19, second bearing 20 (also called driving gear box bearing 20) , transmission gear 21 (also can be referred to as transmission gear ring 21), wherein the rolled material tail pipe 14, the rolled material inlet pipe 15, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com