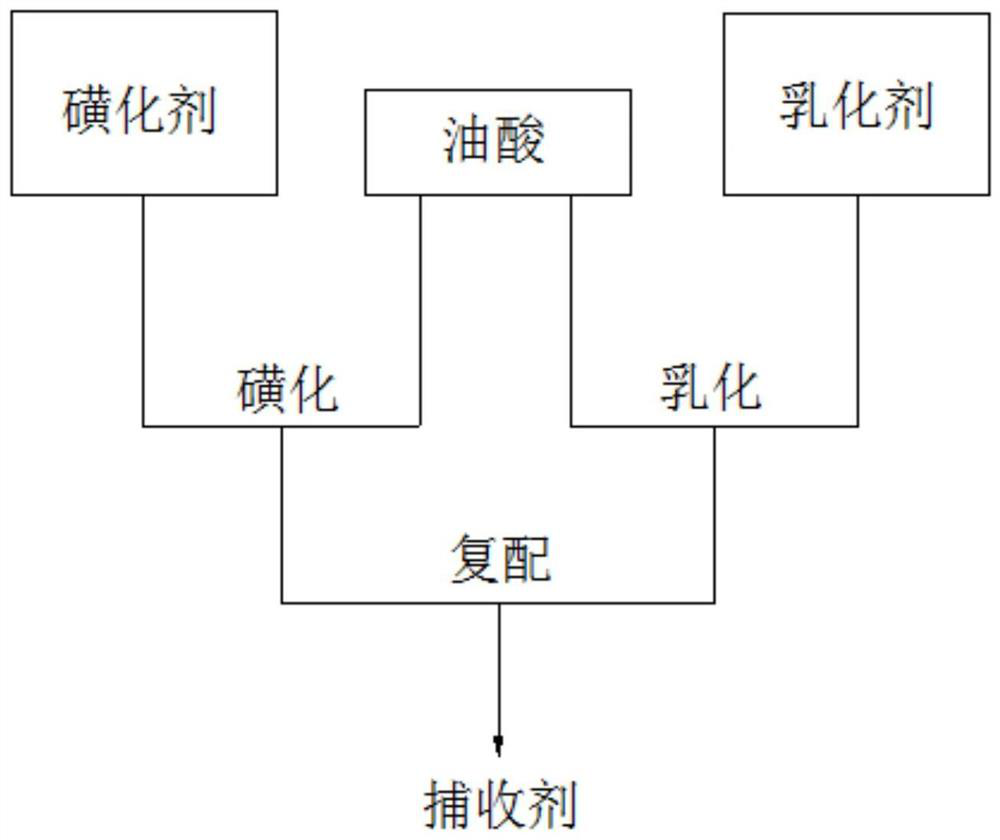

Fluorite flotation collecting agent as well as preparation method and application thereof

A collector, fluorite technology, applied in the field of fluorite beneficiation, can solve the problems of insufficient collection capacity, poor flotation effect, weak foaming ability, etc., and achieve smooth process flow, improved dispersibility, and increased solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a fluorite flotor feeding agent including 10 kg of sulfonated oolic acid and 90 kg of emulsified oil.

[0051] The method of preparing the sulfonated oolic acid comprises the step of adding concentrated sulfuric acid (80% of concentrated sulfuric acid) to the reactor, and then add oleic acid to the reactor (concentrated sulfuric acid and oleic acid. : 50), then warmed to 100 ° C, continuously stirring during the temperature rise, and stirring was continued for 2 hours after the temperature was completed, so that oleic acid and concentrated sulfuric acid had a sulfonation reaction to prepare a sulfonated oil.

[0052] The preparation method of the emulsified oiric acid includes mixing as follows: mixing oleic acid, ethanol, butyl ether (oleic acid, ethanol, and butyl ether is 85: 10: 10: 85: 10: 5), respectively. It was stirred for 0.8 hours to make all raw materials liquid mix evenly emulsified, prepared to obtain emulsified oil.

[0053] The prepar...

Embodiment 2

[0055] This embodiment provides a fluorite flotation induction agent including 18 kg of sulfonated oolic acid and 82 kg of emulsified oil.

[0056] The method of preparation of the sulfonated oil includes the step of adding concentrated sulfuric acid (80% of concentrated sulfuric acid) to the reactor, and then adding oleic acid to the reactor (concentrated sulfuric acid and oleic acid. : 60), then warmed to 120 ° C, continuously stirring during the temperature rise, and stirring was continued for 1 hour after the temperature was completed, so that oleic acid and concentrated sulfuric acid had a sulfonation reaction to prepare a sulfonated oil.

[0057] The preparation method of the emulsified oiric acid includes mixing an oleic acid, ethanol, butyl ether (the mass ratio of oleic acid, ethanol, and butyl ether is 84: 10: 6) in the reactor, at 20 ° C. It was stirred for 1 hour to allow all raw material liquid mixed uniform emulsion to prepare an emulsified oil.

[0058] The preparat...

Embodiment 3

[0060] This embodiment provides a fluorite flotation catching agent, the trapping of the feedstock comprising 20 kg of sulfonated oolic acid and 80 kg of emulsified oil acid,

[0061] The method of preparation of the sulfonated oil includes the step of adding concentrated sulfuric acid (80% of concentrated sulfuric acid) to the reactor, and then adding oleic acid (concentrated sulfuric acid and oleic acid) to the reactor. : 40), then warmed to 100 ° C, continuously stirring during the temperature rise, and stirring was continued for 2 hours after the temperature was completed, so that oleic acid and concentrated sulfuric acid were mixed, and the sulfonated oil is prepared.

[0062] The preparation method of the emulsified oiric acid comprises the step of mixing oleic acid, ethanol, butyl ether (90: 5: 5: 90: 5: 5: 90: 5: 5), at 30 ° C, respectively. It was stirred for 0.5 hours to allow all raw material liquid mixing uniform emulsion to prepare an emulsified oleic acid.

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com