Automatic crushing and grinding processing system for calcium carbonate preparation

A crushing, grinding and processing system technology, which is applied in chemical instruments and methods, solid separation, filtering and sieving, etc. It can solve the problems of unable to adjust the size of calcium carbonate, calcium carbonate stuck inside the system, reducing the flexibility of the system, etc., to achieve enhanced grinding The effect of ensuring the success rate and avoiding the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

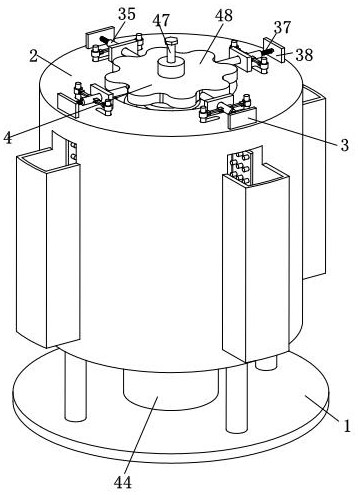

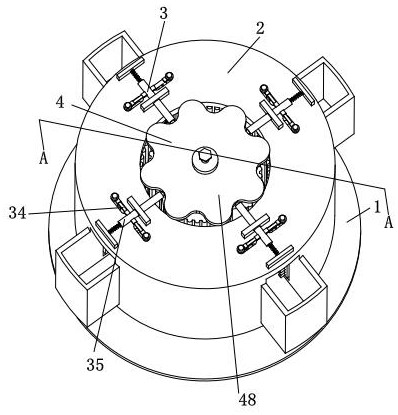

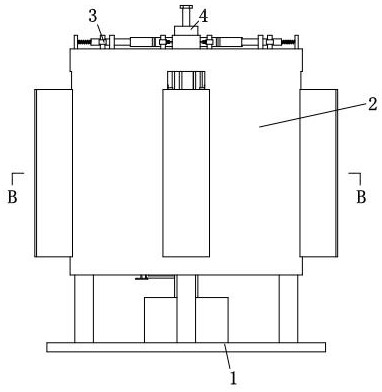

[0029] like Figure 1 to 8 As shown, a calcium carbonate prepared an automated crushing milling system, including the bottom plate 1, the abrasive tube 2, the crushing device 3, and the abrasive device 4, the upper end of the bottom plate 1, by the support column, abrasive pipe 2, abrasive tube 2 side wall The circumference is uniformly opened with a plurality of square through holes, and the inner air inner slide is slidably connected to the crushing device 3, and the abrasive device 4 is mounted in the abrasive tube 2.

[0030] The crushing device 3 includes a broken plate 31, a connection spring 32, a slider 33, a connecting rod 34, a moving rod 35, a mounting plate 36, a reset spring 37, and a strip plate 38, and a square through hole The rectangular groove is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com