Connecting piece and assembling process of cardiovascular implant and conveying equipment

A technology for conveying equipment and connectors, applied in the field of implantation of cardiovascular implants, can solve the problems of increasing the surface area of foreign body content, uneven stress of the implant, deviation and twist of the implant, etc., so as to reduce the risk of falling off, Reduced risk of microthrombi, reduced solder joint effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] see Figure 5 As shown, the embodiment of the present application provides a connector 1 for connecting a cardiovascular implant and a delivery device. The connector 1 includes a main body 11, the main body 11 is formed with a connecting hole 111 and a threaded hole 112, the connecting hole 111 is used for inserting the mounting part of the cardiovascular implant, and the threaded hole 112 is used for threaded connection with the delivery device.

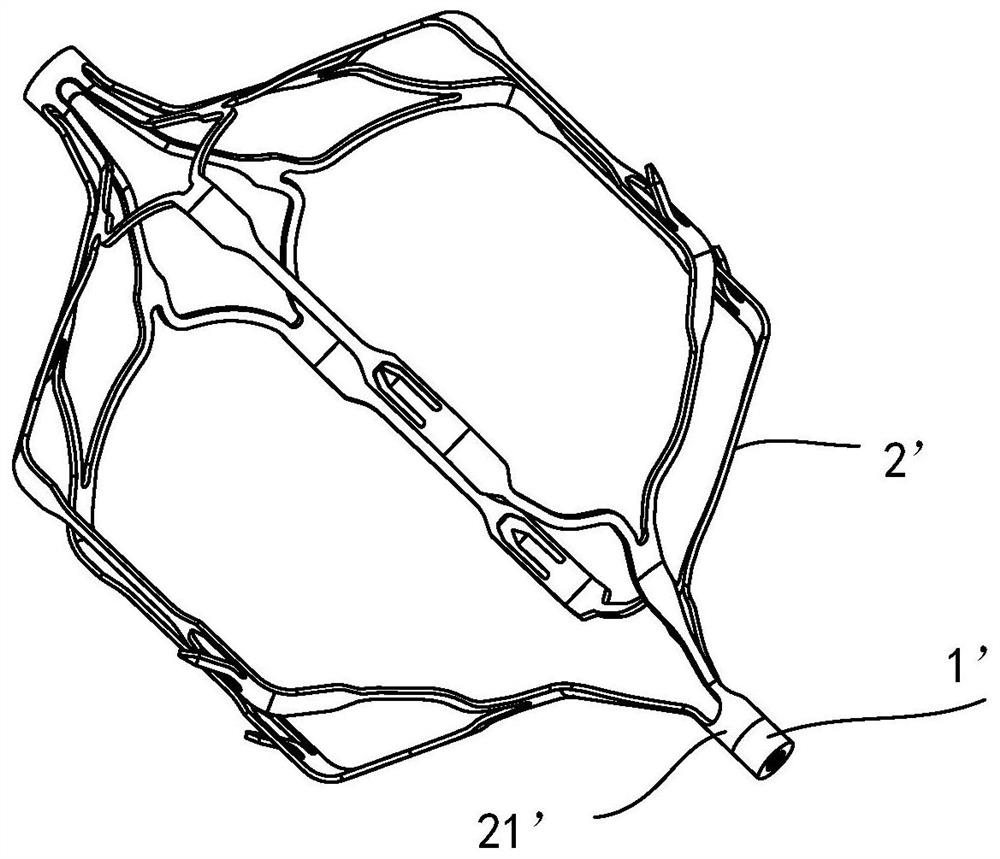

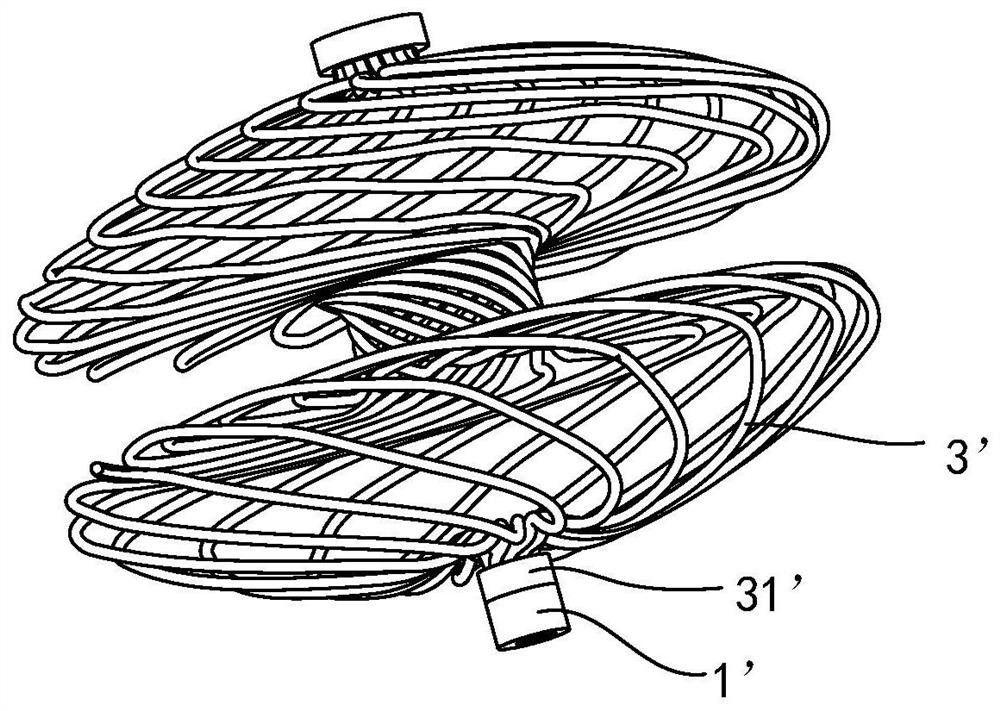

[0056] like Image 6 As shown, when using the connecting piece 1 to connect the tube-like cardiovascular implant 2 and the delivery device, one end of the tube is laser cut into several mounting feet (that is, a short columnar structure, of course, it is not limited to this, and it can also be Set according to actual needs), and then insert each mounting foot evenly into the corresponding connection hole 111 of the connector 1, and then use injection welding to connect each mounting foot to the connector 1, and then use the ...

Embodiment 2

[0067] The connector 1 in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0068] Specifically, such as Figure 10 As shown, the different structures disclosed in Embodiment 2 and Embodiment 1 are as follows:

[0069] There are multiple connecting holes 111 , and the multiple connecting holes 111 plus the threaded holes 112 are arranged in a square array with the threaded holes 112 as the center. Here, for example, there are eight connecting holes 111 , one threaded hole 112 is located in the center, and nine connecting holes 111 and threaded holes 112 are arranged in a square array.

Embodiment 3

[0071] The connector 1 in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0072] Specifically, such as Figure 11 As shown, the different structures disclosed in Embodiment 3 and Embodiment 1 are as follows:

[0073] The number of connecting holes 111 is multiple, and the multiple connecting holes 111 are arranged in a circular array around the threaded hole 112;

[0074] The number of array rings formed is multiple (that is, a plurality of ring structures centered on the threaded hole 112 and having unequal radii, and any ring structure is formed by a plurality of connecting holes 111 at intervals in sequence), and The connection holes 111 in any two adjacent array rings are arranged alternately. Here, for example, one threaded hole 112 is located at the center, the number of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com