Focused ion beam processing apparatus

A processing device and ion beam technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as reduced operating efficiency, residual processing stripes, and increased beam diameter, and achieve the effect of improving operating efficiency and improving cross-sectional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

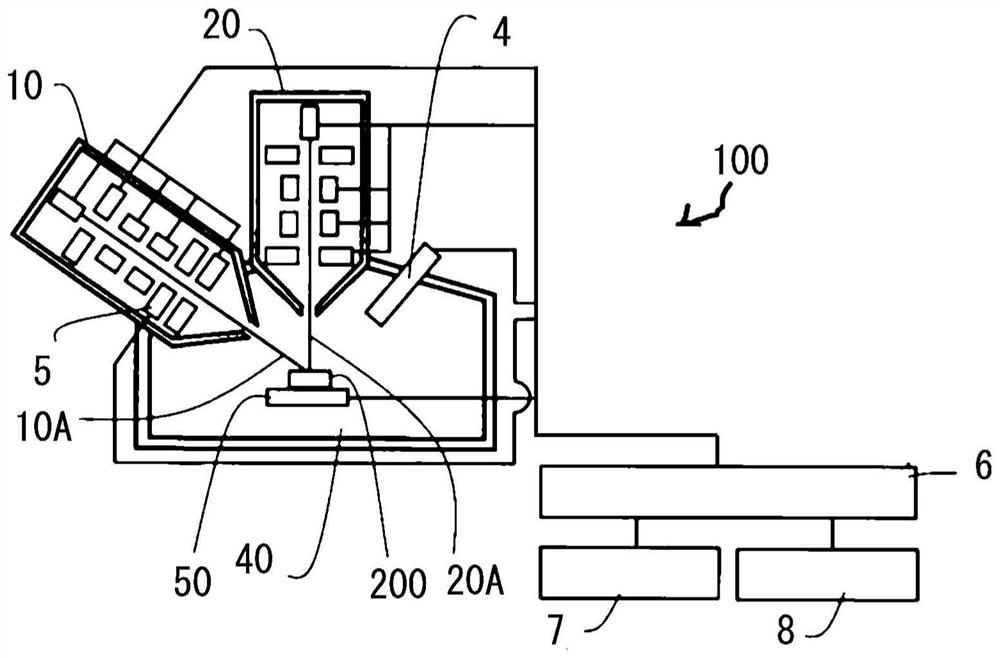

[0074] figure 1 It is a block diagram showing the overall configuration of the convergent ion beam processing apparatus 100 according to the embodiment of the present invention. exist figure 1 Among them, the convergent ion beam processing apparatus 100 has an electron beam column (SEM column) 10, a convergent ion beam column (FIB column) 20, secondary electron detectors 4, 5, a control unit 6, a display unit 7, an input The unit 8 and the sample stage 50 can process the sample 200 arranged on the sample stage 50 with a converged ion beam, and observe it with a SEM.

[0075] Also, while in figure 1 In the embodiment, the FIB column 20 is arranged vertically, and the SEM column 10 is arranged inclined at a predetermined angle with respect to the vertical, but the present invention is not limited thereto.

[0076] Some or all of the components of the converged ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com