Dry type transformer aluminum alloy clamp

A technology of dry-type transformers and aluminum alloys, which is applied in the directions of transformer/inductor cores, transformer/inductor coils/windings/connections, etc., which can solve the problem of high temperature of aluminum alloy clamps, reduced clamping force of transformers, and welding problems. Reduce the strength of parts and other problems, and achieve the effect of reducing the degree of bimetallic contact corrosion, increasing strength and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

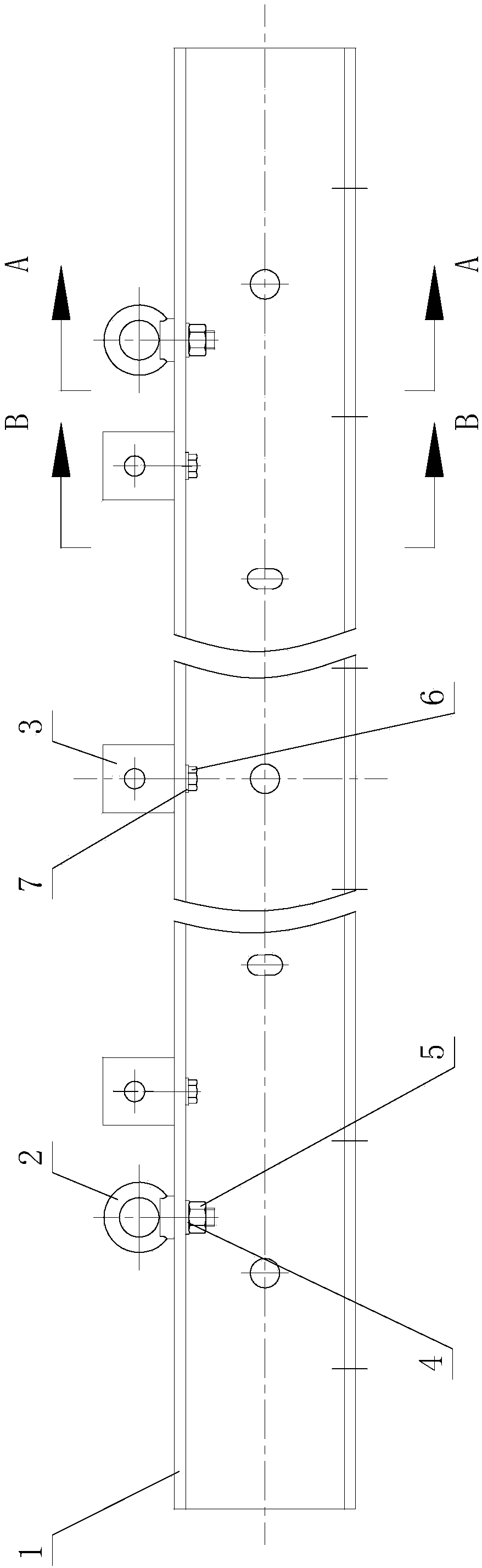

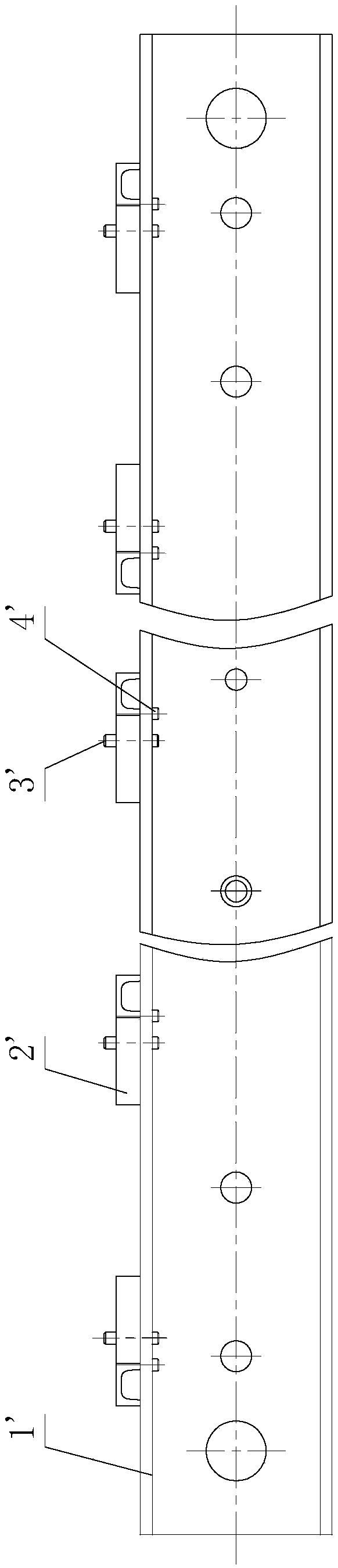

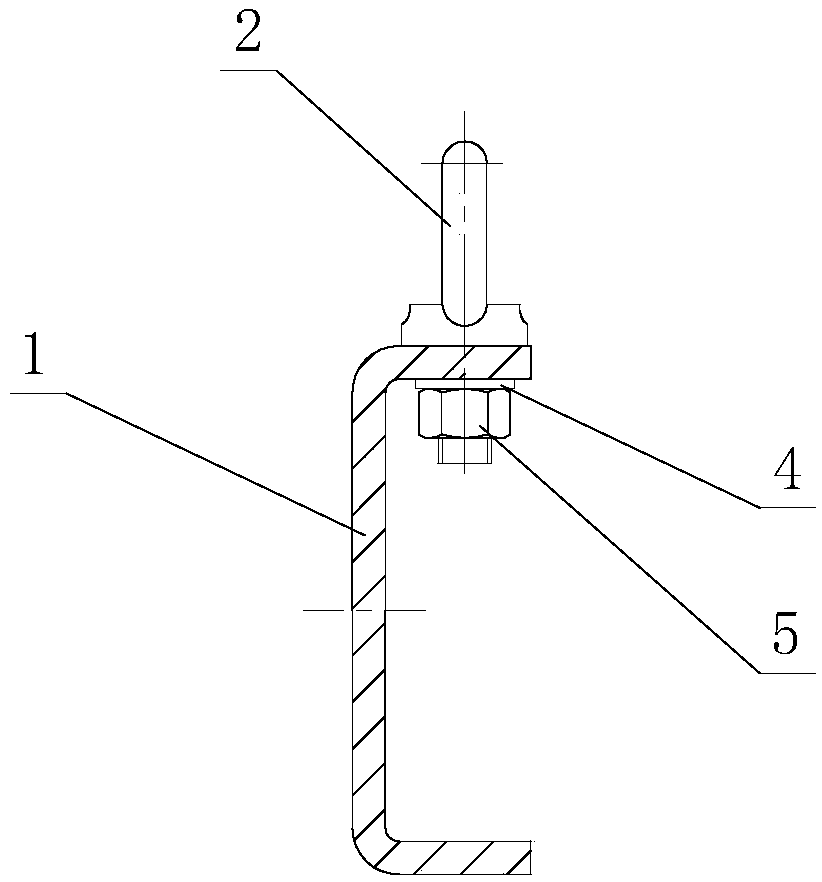

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] see Figure 1-Figure 5 , the dry-type transformer aluminum alloy clamp, including the upper clamp 1 and the lower clamp 1', the upper clamp 1 and the lower clamp 1' are made of 6061-T6 aluminum alloy material, and the total weight of the transformer is not more than 3 The maximum temperature during use does not exceed 155°C. The surface of the upper clamp 1 and the lower clamp 1' is anodized, and the thickness of the anodized film is 8-10 μm. The anodized film is used as a protective layer, which can greatly improve the The corrosion resistance of the clamp surface prolongs the service life.

[0033] The 6061-T6 aluminum alloy is composed of the following chemical components in parts by mass: 0.4-0.8 Si, 0.7 Fe, 0.15-0.4 Cu, 0.15 Mu, 0.8-1.2 Mg, 0.04-0.35 Cr, 0.25 0.15% of Zn, 0.15% of Ti, and the rest of Al.

[0034] The mechanical properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com