Integrated jacket ball valve

A one-piece, jacketed technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of poor sealing effect of end caps and difficult assembly of end caps, and achieve easy installation and good sealing performance , processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

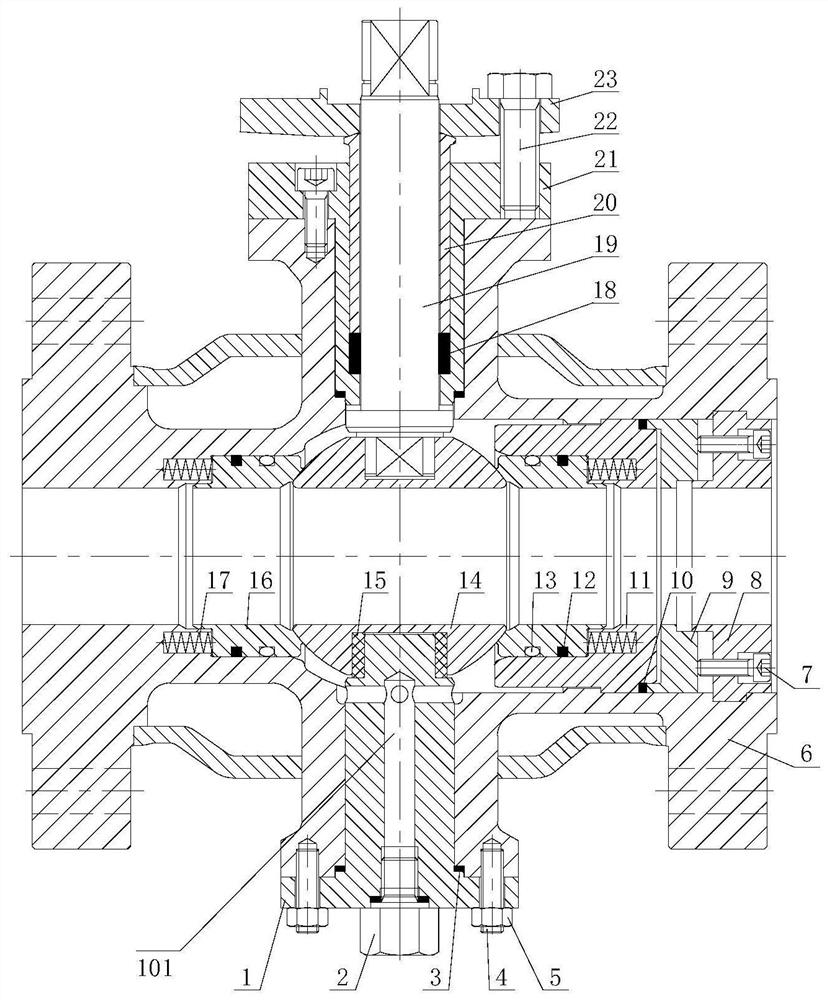

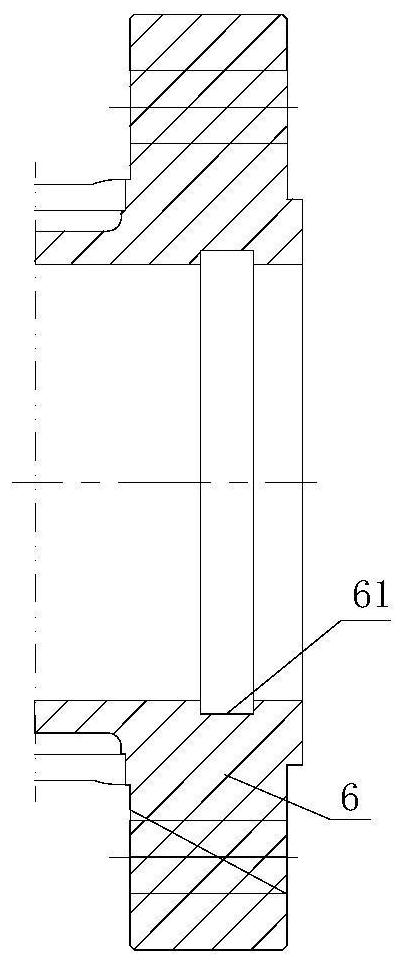

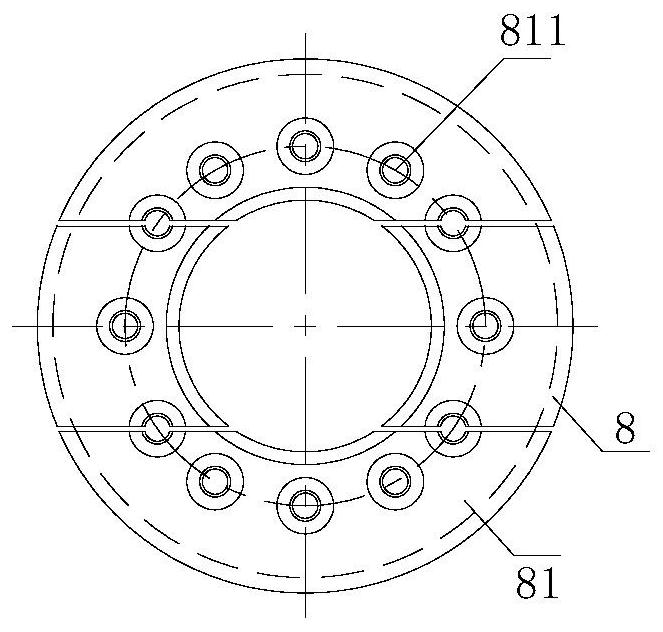

[0033] Such as Figure 1-6 As shown, an integrated jacketed ball valve includes a valve body 6, an end cover 8 and a valve ball 14 are installed in the valve body 6, a sealing pressure ring 9 and a support ring 11 are installed in the valve body 6, and the support ring 11 is The valve seat 16 is installed, the seal 10 is installed between the support ring 11 and the sealing pressure ring 9; the valve body 6 has a snap-in groove 61, and the outer surface of the end cover 8 is integrally formed with an outer ring 812, which can be snapped The end cover 8 is evenly opened with a plurality of fastening holes 811 , and fastening pieces that can be in contact with the sealing pressure ring 9 are installed in the fastening holes 811 .

[0034] Preferably, the fastener is a hexagon socket head cap screw 7, the seal 10 is a gasket, an O-ring 13 and a braided graphite 12 are installed between the valve seat 16 and the support ring 11, and a plurality of spring holes 112 are opened in th...

Embodiment 2

[0037] Such as Figure 1-5 As shown, on the basis of the above-mentioned embodiment 1, this embodiment provides a preferred structure that can make the end cover 8 easier to install: the end cover 8 includes a plurality of end face blocks 81 that are independent of each other, and each end face block 81 Both have fastening holes 811 , and an outer ring 812 is integrally formed on the outer surface of each end block 81 .

[0038]In this embodiment: the dividing line is on the fastening hole 811, which can effectively prevent the end cover 8 from sliding and falling off towards the middle cavity of the valve body 6, and can stabilize the position of the end cover 8, because the end cover 8 includes a plurality of independent end face blocks 81 , so the gap between the dividing lines of the end cover 8 can be made relatively large, and the outer rings 812 of the divided end face blocks 81 are snapped into the snap-fit grooves 61 from the inside to the outside respectively, whil...

Embodiment 3

[0041] Such as figure 1 As shown, on the basis of the above-mentioned embodiment 1, this embodiment provides a preferred structure that can further make the sealing performance of the entire ball valve better: one end of the valve ball 14 is installed with a lower end that passes through the valve body 6 Valve stem 1, there is a channel 101 communicating with the valve body 6 in the lower valve stem 1, a screw plug 2 is installed in the channel 101, the valve body 6 and the lower valve stem 1 are connected by a stud 4, and the stud 4 is installed with A winding pad 3 is installed between the nut 5, the valve body 6 and the lower valve stem 1 . By installing the winding gasket 3 between the valve body 6 and the lower valve stem 1, the sealing performance between the valve body 6 and the lower valve stem 1 can be improved.

[0042] Preferably, the other end of the valve ball 14 is equipped with an upper valve stem 19 passing through the valve body 6, and a stuffing box 21 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com