Shock absorption and impact resistance leveling assembly for assembly type ground

An anti-shock adjustment and assembly technology, applied in the direction of floors, elastic floors, local raised floors, etc., can solve the problems of complex secondary leveling operations, small adjustable range, and low leveling accuracy, so as to reduce fluctuations and vibrations. , to ensure the effect of flatness and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

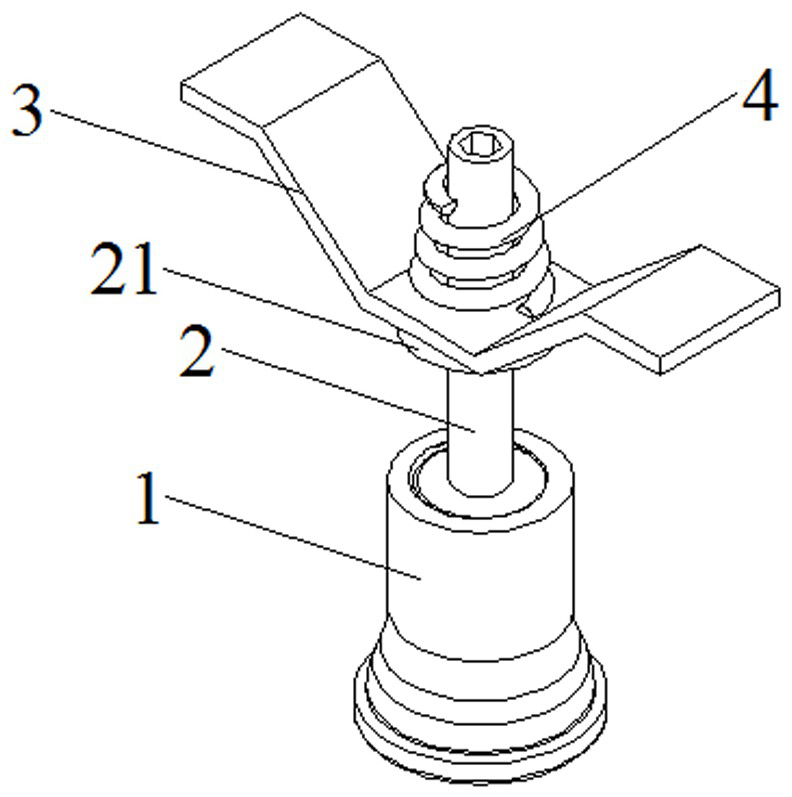

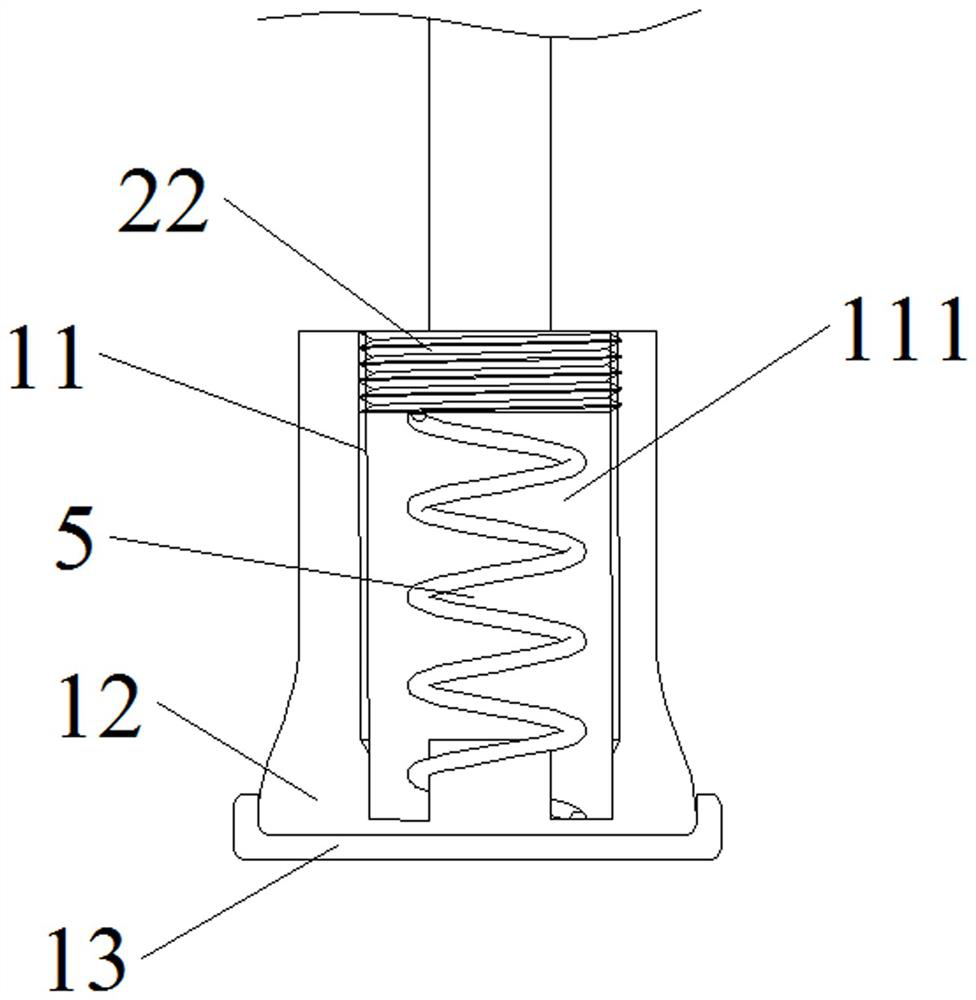

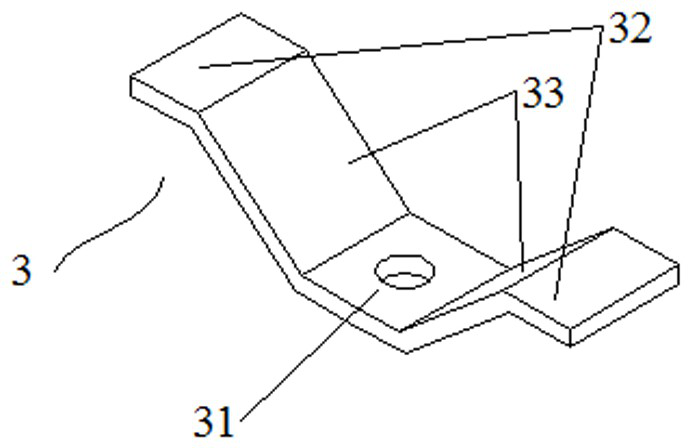

[0031] figure 1 It is a schematic diagram of a shock-absorbing and anti-impact leveling assembly for an assembled floor, Figure 5 Schematic diagram for the leveling screw, such as figure 1 and Figure 5 As shown, a shock-absorbing and shock-resistant leveling assembly for an assembled floor includes a leveling base 1, a leveling screw 2 set on the leveling base 1, and a base plate set on the leveling screw 2 The support seat 3, the support member 21 arranged under the substrate support seat 3 and used to receive the substrate support seat 3, and the support set on the leveling screw 2 above the substrate support seat 3 Spring 4, the support member 21 is screwed to the leveling screw 2; the substrate support seat 3 includes a first platform 31 arranged on the support member 21, a second platform adjacent to the substrate The platform 32 and the connecting portion 33 arranged between the first platform 31 and the second platform 32 and the upper and lower edges are respectiv...

Embodiment 2

[0039] Compared with the example 1, the shock-absorbing and shock-resistant leveling assembly for the assembled floor in the embodiment of the present invention differs in that the structure of the base plate support seat is different. Figure 4 It is a schematic diagram of the substrate support seat described in embodiment 2, as Figure 4 As shown, the first platform 31 is a circular platform, the connecting portion 33 is a hollow circular platform whose lower edge is connected with the edge of the first platform 31, and the second platform 32 is a The connecting portion 33 is connected to the annular platform on the edge. The radius of the upper edge of the connecting portion 33 is larger than the radius of the lower edge.

[0040] The method of assembling and using the shock-absorbing and anti-impact leveling component of the fabricated ground according to the present invention is as follows:

[0041] Set the leveling base 1 on the original ground, set the limit spring 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com