Multi-directional leveling module of fabricated wallboard and mounting method

A prefabricated and wall panel technology, applied in covering/lining, building, building structure, etc., can solve problems such as inability to fix the angle, difficulty in leveling, time-consuming and laborious installation, etc., achieve safe and convenient installation process, and reduce installation process , the effect of expanding the leveling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

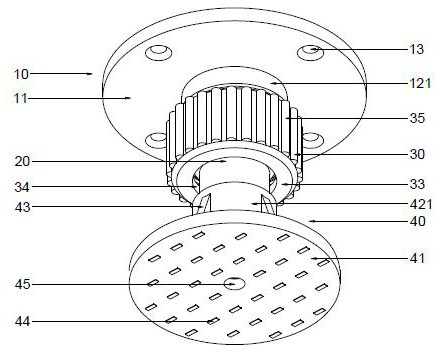

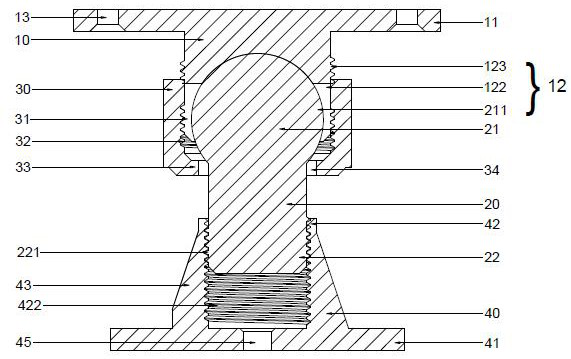

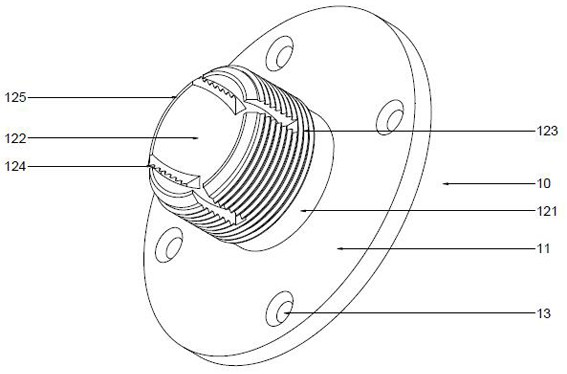

[0047] Such as Figure 1~8 As shown, a multi-directional leveling module of a prefabricated wall panel includes a wall fixing seat 10, which includes a connecting plate 11 for connecting with the base wall 50, and the surface of the connecting plate 11 is located at its corner Two pairs of screw holes 13 are provided, so the connecting plate 11 can be fixedly installed on the surface of the base wall 50 by screws. At the same time, in order to improve the shock absorption effect of the whole leveling module, a shock absorption layer 14 is provided between the connecting plate 11 and the base wall 50 in the present invention.

[0048] One end surface of the connecting plate 11 is provided with a first angle adjustment mechanism 12, and its specific structure is as follows: the first angle adjustment mechanism 12 includes a threaded column 121 made of hard plastic, and a spherical accommodation cavity is arranged at the center of its top 122 , a first fixing thread 123 is provi...

Embodiment 2

[0062] see Figure 1~8 As shown, a method for using a multi-directional leveling module of a prefabricated wall panel includes the following steps:

[0063] (S.1) Pass the screw through the screw hole 13, and fix the connecting plate 11 of the wall fixing seat 10 on the base wall 50.

[0064] (S.2) Through the cooperation of the first angle adjustment mechanism 12 and the second angle adjustment mechanism 21, specifically, the universal adjustment rod 20 is rotated, so that the ball head 211 rotates inside the accommodation cavity 122, when the universal adjustment rod 20 is adjusted to the plate base 40 in a horizontal state, which is the most suitable angle at this moment. Then tighten the connecting fastener 30, when the second fixing thread 32 is mated with the first fixing thread 123, the ball head 211 is pressed tightly by the connecting fastener 30, so that the rotation of the ball head 211 can be limited, so that the fixed universal adjustment Angle of rod 20.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com