Drying method for preventing paper from wrinkling and deforming after water-based deacidification

A drying method and deacidification technology, which is applied in the post-treatment of waste paper, physical treatment of paper, and post-printing, etc., can solve the problems of paper wrinkle deformation, difficult speed control, uneven moisture distribution, etc., and restore the moisture content to normal , uniform distribution, and reduce the effect of uneven shrinkage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

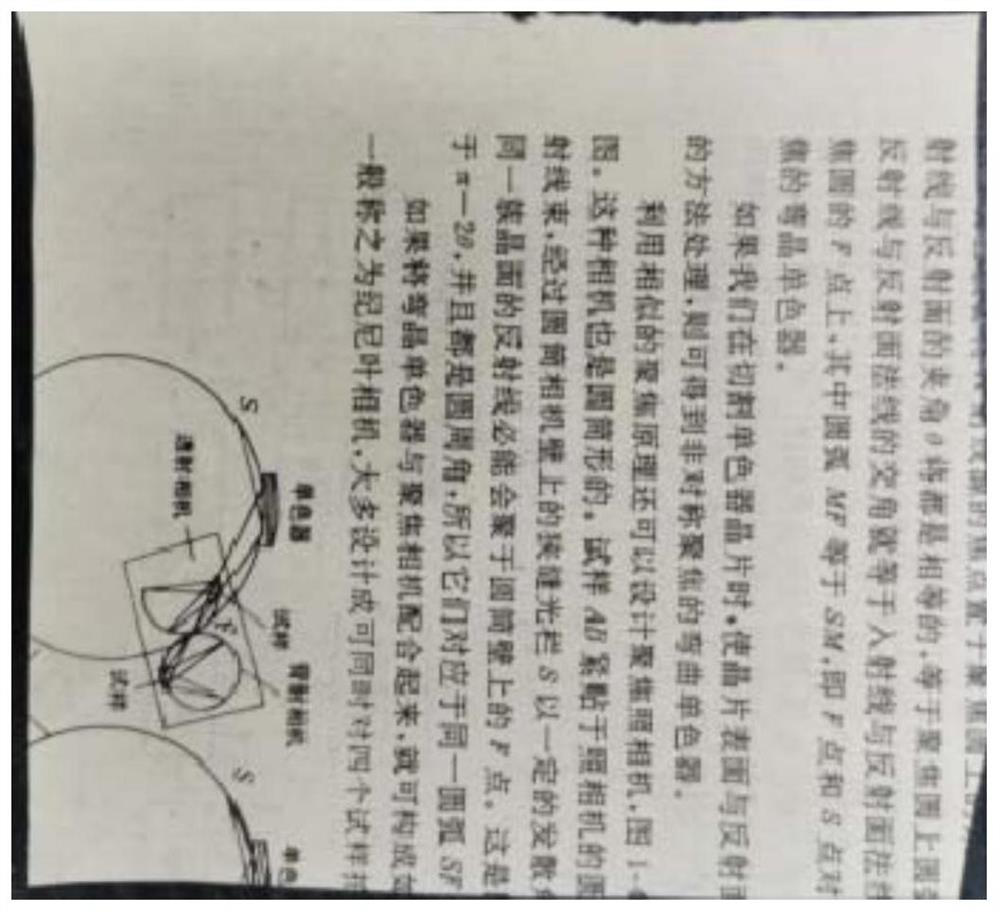

Image

Examples

Embodiment 1

[0033] Place the paper to be deacidified in a deacidified treatment box with a temperature of 50°C and a relative humidity of 90%, select 5wt% calcium hydroxide solution as the deacidified solution, and spray the deacidified solution in the deacidified treatment chamber. The paper is sprayed for 10 minutes. After the treatment is completed, the deacidified paper is placed on the cotton net 10 cm above the grounding plate, and the plate connected to the output end of the high-voltage power supply is 30 cm above the grounding plate. The paper is placed Finally, turn on the high-voltage power supply, adjust the output voltage to 8kV, and start dehydration and drying assisted by a high-voltage electric field. After 60 minutes of treatment, take out the dried paper to complete the non-destructive and uniform deacidification of the paper.

[0034] Performance Testing:

[0035] The method for detecting the deacidification effect of the paper in this embodiment is to divide the paper ...

Embodiment 2

[0054] The deacidification solution in the deacidification treatment process of Example 1 is replaced by 5wt% magnesium bicarbonate aqueous solution, and the rest are the same as the operation steps of Example 1, and the non-destructive drying after the uniform deacidification of the paper can be completed. The values are evenly distributed, the surface morphology is basically the same as that of the base paper, and there is no obvious wrinkle deformation.

Embodiment 3

[0056] The temperature of the deacidification treatment box in Example 1 is adjusted to 55° C., and the relative humidity is 95% in the deacidification treatment box. The rest are the same as the operation steps of Example 1, and the non-destructive drying after the uniform deacidification of the paper can be completed. The pH value is evenly distributed everywhere, and the surface morphology is basically the same as that of the base paper, without obvious wrinkle deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com