Device and electrolysis method for preparing potassium formate by electrolyzing carbon dioxide

A technology of carbon dioxide and electrolysis method, which is applied in the direction of electrolysis components, electrolysis process, electrolysis organic production, etc., can solve the problems that the product is difficult to separate, and there is no report on the operation method of potassium formate, so as to reduce production costs, facilitate product separation, and improve the production process. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

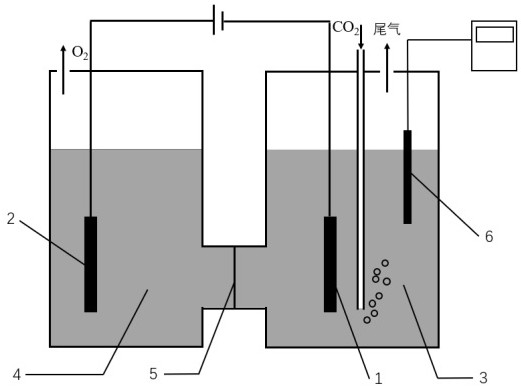

[0031] This embodiment provides a device for electrolyzing carbon dioxide to produce potassium formate, such as figure 1 Shown: the device includes an anode chamber and a cathode chamber, the anode chamber and the cathode chamber are connected by a cation exchange membrane 5, the cation exchange membrane 5 is a Nafion membrane, and an oxygen discharge port is arranged on the top of the anode chamber, The anode chamber is equipped with an anolyte 4, and the anolyte 4 is an acidic or neutral electrolyte; the top of the cathode chamber is provided with an exhaust outlet and a carbon dioxide inlet, and the cathode chamber is equipped with a catholyte 3, and the catholyte 3 is an alkaline electrolyte, the anode chamber is provided with an anode electrode 2, and the cathode chamber is provided with a carbon dioxide access pipe, a pH meter 6 and a cathode electrode 1, and the anode electrode 2 is electrically connected to the cathode electrode 1; One end of the carbon dioxide inlet p...

Embodiment 2

[0038] The present embodiment provides a kind of electrolytic cell device of electrolyzing carbon dioxide to produce potassium formate, such as figure 1 Shown: the device includes an anode chamber and a cathode chamber, the anode chamber and the cathode chamber are connected by a cation exchange membrane 5, the cation exchange membrane 5 is a Nafion membrane, and an oxygen discharge port is arranged on the top of the anode chamber, The anode chamber is equipped with an anolyte 4, and the anolyte 4 is an acidic or neutral electrolyte; the top of the cathode chamber is provided with an exhaust outlet and a carbon dioxide inlet, and the cathode chamber is equipped with a catholyte 3, and the catholyte 3 is an alkaline electrolyte, the anode chamber is provided with an anode electrode 2, and the cathode chamber is provided with a carbon dioxide access pipe, a pH meter 6 and a cathode electrode 1, and the anode electrode 2 is electrically connected to the cathode electrode 1; One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com