Control method for protective atmosphere of bell-type annealing furnace

A bell-type annealing furnace and protective atmosphere technology, applied in the direction of bell-type annealing furnace, heat treatment process control, furnace, etc., to achieve the effect of eliminating chromatic aberration defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

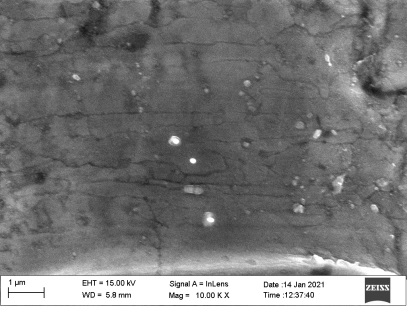

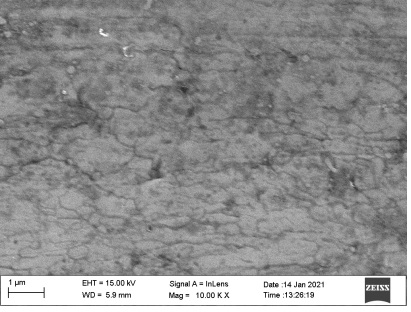

Image

Examples

Embodiment 1

[0035] The DC04 product is produced by bell furnace annealing, and the thickness of the product is 1.0mm. Among them, the oxygen content of hydrogen is 5ppm, the dew point is -50°C, and the purity is 99.999%; the oxygen content of nitrogen is 4.5ppm, the dew point is -45°C, and the purity is 99.999%.

[0036] The control method is as follows:

[0037] 1) Inner cover cold seal test inspection: the inner cover pressure is 5KPa, within 15 minutes, the pressure drops to 950Pa, then the cold seal test is qualified;

[0038] 2) Safety purge: Before the annealing heating starts, use the protective gas N 2 To purge the air in the inner cover on the furnace table, the nitrogen flow rate is 120Nm 3 / h, nitrogen purge volume 81m 3 , the purge pressure is 3bar, and the residual oxygen concentration in the furnace atmosphere is 1%;

[0039] 3) After the safety purge is completed, fasten the heating cover, start the annealing program and heat according to the established annealing proce...

Embodiment 2

[0044] The HC340LA product is produced by bell furnace annealing, and the thickness of the product is 1.2mm. Among them, hydrogen has an oxygen content of 4ppm, a dew point of -60°C, and a purity of 99.9997%; nitrogen has an oxygen content of 5ppm, a dew point of -40°C, and a purity of 99.9996%.

[0045] The control method is as follows:

[0046] 1) Inner cover cold seal test inspection: The inner cover pressure is 5KPa, within 15 minutes, the pressure drops to 800Pa, and the cold seal test is qualified;

[0047] 2) Safety purge: Before the annealing heating starts, use the protective gas N 2 To purge the air in the inner cover on the furnace table, the nitrogen flow rate is 120Nm 3 / h, nitrogen purge volume 81m 3 , the purge pressure is 7bar, and the residual oxygen concentration in the furnace atmosphere is 0.5%;

[0048] 3) After the safety purge is completed, fasten the heating cover, start the annealing program and heat according to the established annealing process. ...

Embodiment 3

[0053] The DC01 product is produced by bell furnace annealing, and the thickness of the product is 0.8mm. Among them, hydrogen has an oxygen content of 3ppm, a dew point of -55°C, and a purity of 99.999%; nitrogen has an oxygen content of 4ppm, a dew point of -48°C, and a purity of 99.9992%.

[0054] The control method is as follows:

[0055] 1) Inner cover cold seal test inspection: the inner cover pressure is 5KPa, within 15 minutes, the pressure drops to 400Pa, and the cold seal test is qualified;

[0056] 2) Safety purge: Before the annealing heating starts, use the protective gas N 2 The air in the inner cover on the stove top is purged. Nitrogen flow 120Nm 3 / h, nitrogen purge volume 81m 3 , the purge pressure is 5bar, and the residual oxygen concentration in the furnace atmosphere is 0.3%;

[0057] 3) After the safety purge is completed, fasten the heating cover, start the annealing program and heat according to the established annealing process. During the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com