A CDQ cycle gas explosion-proof equipment

A technology of circulating gas and explosion-proof equipment, which is applied in the field of CDQ engineering, can solve the problems of insufficient mixing of combustible component gas and air, insufficient combustion of combustible component gas, and reducing the concentration of combustible component gas, so as to avoid explosion phenomenon and structure. Reasonable, reduce the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

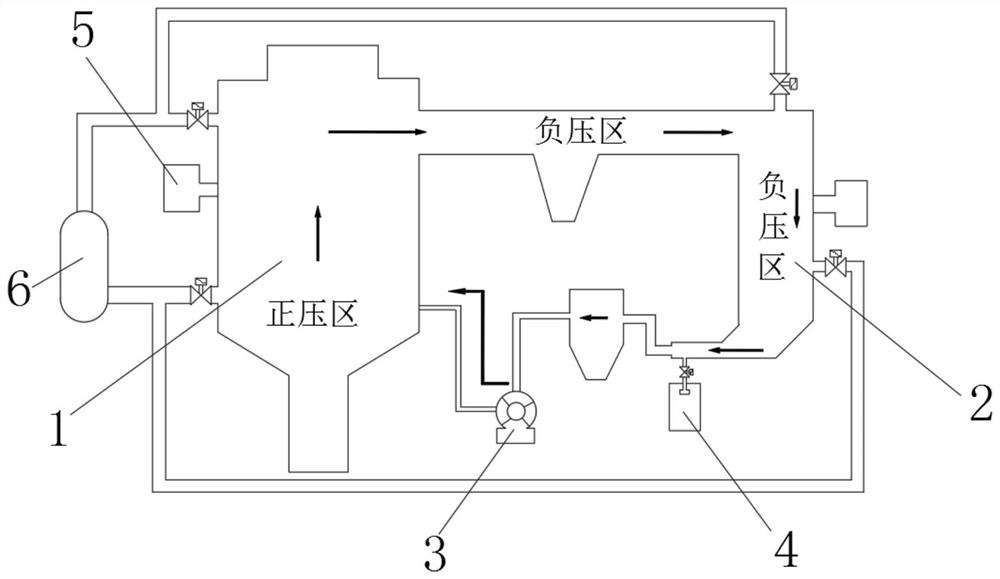

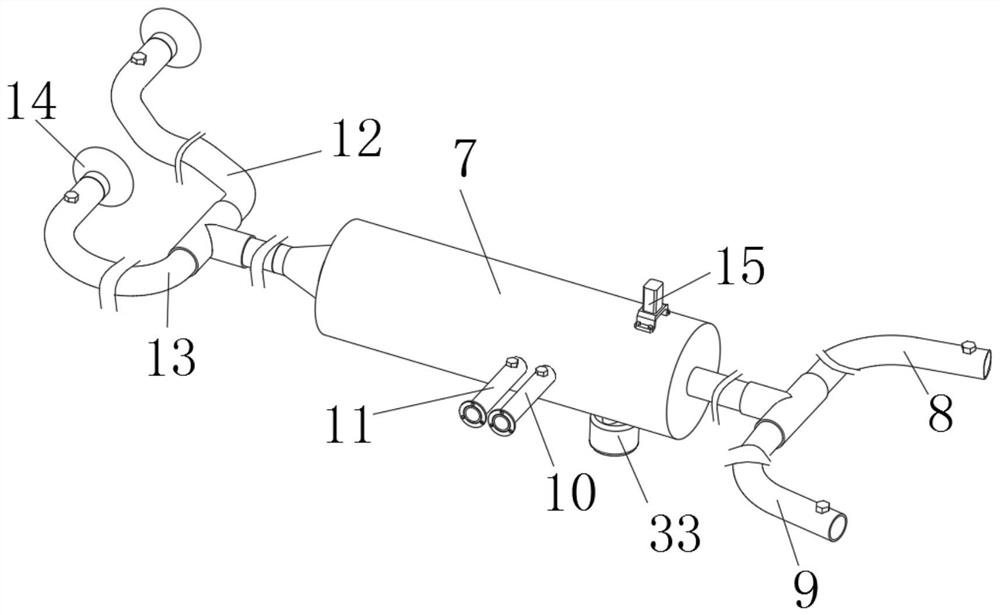

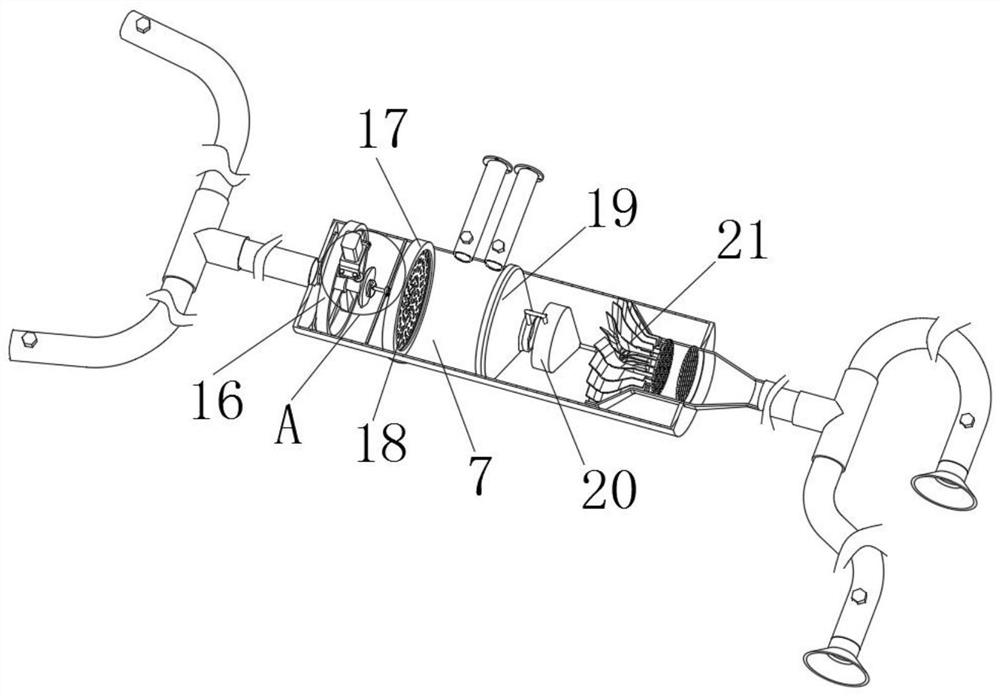

[0036] Example: Reference Figure 1-5 The shown CDQ circulating gas explosion-proof equipment includes a CDQ furnace 1, a boiler 2, a dust collector, a circulating fan 3, a circulating gas connecting pipe, and also includes a circulating gas monitoring system and a circulating gas mixing mechanism 6;

[0037] CDQ Furnace 1, Boiler 2, Dust Collector, and Circulating Fan 3 are connected through a circulating gas communication pipe, and a circulating gas dispersion pipe is installed on the side wall of the circulating gas communication pipe located in the negative pressure area on one side of the boiler 2, and the circulating gas dispersion pipe The gas outlet end is equipped with a circulating gas dispersion processing module 4, and the circulating gas dispersion processing module 4 is used to purify the dispersed circulating gas;

[0038] The circulating gas mixing mechanism 6 is used to mix the circulating gas in the positive pressure zone and the negative pressure zone with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com