Mangiferin extraction and separation method

A separation method and technology of mangiferin, applied in the direction of organic chemistry, can solve the problems of denaturation and inactivation of mangiferin, instability of mangiferin, low economic benefit, etc., and achieve the effect of short processing time, low cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

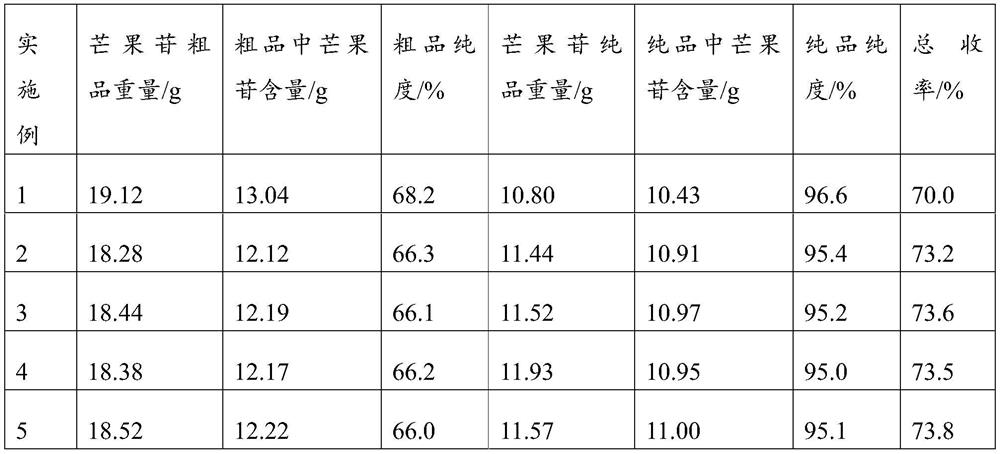

Examples

Embodiment 1

[0027] A method for extracting and separating mangiferin, comprising the steps of:

[0028] (1) Put 1 kg of mango leaves into a high-pressure tank for 2 minutes after crushing, keep the pressure in the tank at 20 MPa, and the temperature in the tank at 25 °C, and then release the pressure to normal pressure within 0.3 s.

[0029] (2) Take out the mango leaf of step (1), add 3L ethyl acetate, and pass into micro-nano bubbles with a diameter of 200nm, seal and soak for 3h, then shake for 10min, filter with a 200-mesh filter screen, and extract repeatedly 3 times, Every time the micro-nano bubbles are supplemented in the mixed material, so that the number of micro-nano bubbles contained in every liter of ethyl acetate is 10.0×10 7 until the green color of the extract basically disappears, take the mango leaf residue.

[0030] (3) Percolate the mango leaf residue in step (2) by using an aqueous acetone solution with a volume fraction of 60%, combine the percolation solution, conc...

Embodiment 2

[0034] A method for extracting and separating mangiferin, comprising the steps of:

[0035] (1) Put 1 kg of mango leaves into a high-pressure tank after being crushed for 5 minutes to keep the pressure in the tank at 19 MPa and the temperature in the tank at 23 °C, and then release the pressure to normal pressure within 0.3 s.

[0036] (2) Take out the mango leaves of step (1), add 3.1L ethyl acetate, and pass into micro-nano bubbles with a diameter of 500nm, seal and soak for 2.8h, then shake for 15min, filter with a 200-mesh filter screen, and repeatedly extract 3 Every time, the micro-nano bubbles are added to the mixed material, so that the number of micro-nano bubbles contained in each liter of ethyl acetate is 8.5 × 10 7 until the green color of the extract basically disappears, take the mango leaf residue.

[0037] (3) Percolate the mango leaf residue in step (2) by using an aqueous acetone solution with a volume fraction of 65%, combine the percolation solution, conce...

Embodiment 3

[0041] A method for extracting and separating mangiferin, comprising the steps of:

[0042] (1) Put 1kg of mango leaves into a high-pressure tank after being crushed for 8 minutes to keep the pressure in the tank at 17MPa and the temperature in the tank at 21°C, and then release the pressure to normal pressure within 0.2s.

[0043] (2) Take out the mango leaf of step (1), add 3.2L ethyl acetate, and feed into micro-nano bubbles with a diameter of 5 μm, seal and soak for 2.5 hours, then shake for 12 minutes, filter with a 200-mesh filter screen, and repeatedly extract 2 Every time, the micro-nano bubbles are added to the mixed material, so that the number of micro-nano bubbles contained in each liter of ethyl acetate is 6.0×10 7 until the green color of the extract basically disappears, take the mango leaf residue.

[0044] (3) Percolate the mango leaf residue in step (2) with a 70% ethanol aqueous solution, combine the percolation solution, concentrate at 45° C., remove ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com