Method for extracting natural active ingredients from plants by through cold explosion technology

A technology of active ingredients and plants, which is applied in the field of extracting natural active ingredients of plants by using cold explosion technology, can solve the problems of unrecorded natural active ingredients of plants, difficult cleaning of high-pressure devices, low production efficiency, etc., and achieve economic benefits of production, good Social benefit and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

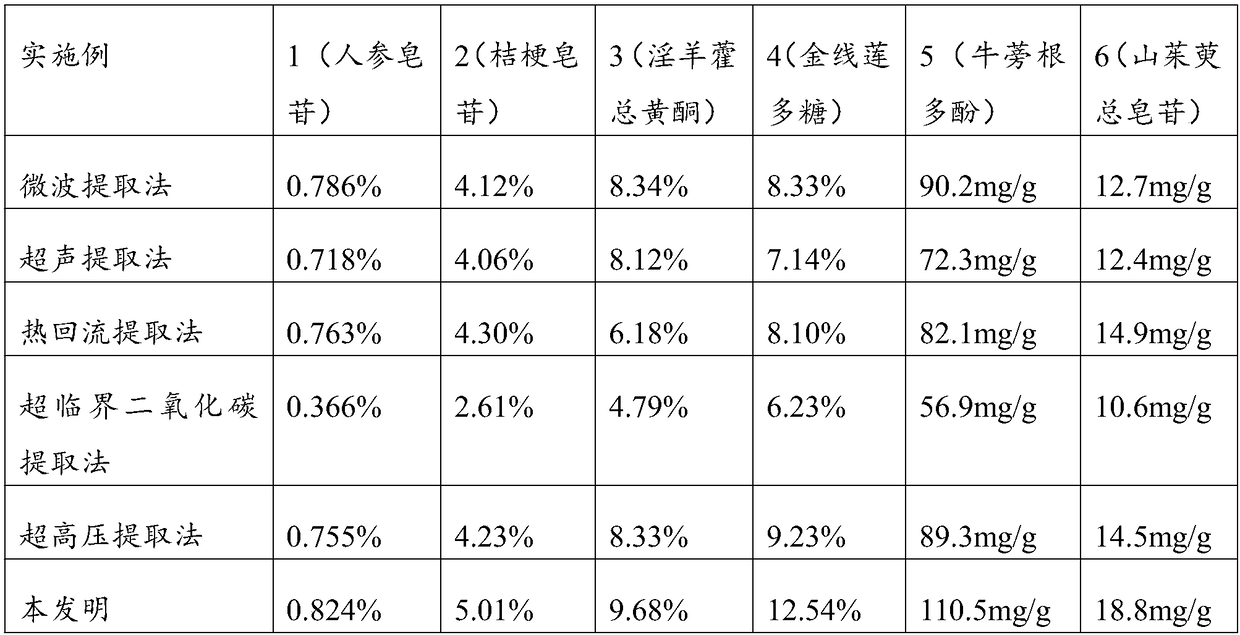

Examples

Embodiment 1

[0023] Cut ginseng into 5mm strips and put them into a high-pressure tank, fill the high-pressure tank with air at 15°C until the pressure in the high-pressure tank reaches 10 MPa and keep the pressure for 15 minutes, then release the pressure of the high-pressure tank to normal within 0.1s Press the ginseng material in the tank to cause cold explosion, collect the ginseng material after the cold explosion, add methanol with a volume fraction of 90% according to the material ratio of 1:28, soak for 10min and stir at 15°C, and control the stirring speed to 50rpm. Then filter, take the filtrate, evaporate the methanol in the filtrate at 35°C, control the evaporation time to 60min, and the remaining solid product is the natural active ingredient of ginseng; collect the evaporated methanol, and reuse it after purification.

Embodiment 2

[0025] Cut platycodon root into 12mm strips and put it into a high-pressure tank. Fill the high-pressure tank with nitrogen at 18°C until the pressure in the high-pressure tank reaches 15 MPa and keep the pressure for 12 minutes, then release the pressure of the high-pressure tank to normal within 0.3s. Press down, make the bellflower material in the tank cold burst, collect the bellflower material after the cold explosion, add volume fraction by the material ratio of 1:100 is 55% methanol, soak 9min and stir at 18 ℃, the control stirring speed is 50rpm, Then filter, take the filtrate, evaporate the methanol in the filtrate at 37°C, control the evaporation time to 140min, and the remaining solid product is the natural active ingredient of Platycodon grandiflora; collect the evaporated methanol, purify and reuse.

Embodiment 3

[0027] Cut Epimedium into 20mm strips and put them into a high-pressure tank, fill the high-pressure tank with carbon dioxide at 22°C until the pressure in the high-pressure tank reaches 20 MPa and keep the pressure for 10 minutes, then release the pressure in the high-pressure tank within 0.3s To normal pressure, the Epimedium material in the tank is cold-exploded, and the Epimedium material after the cold-explosion is collected, and the volume fraction is 95% ethanol added at a material ratio of 1:50, soaked at 20°C for 7min and stirred, Control the stirring speed to 40rpm, then filter, take the filtrate, evaporate the ethanol in the filtrate at 39°C, control the evaporation time to 200min, the remaining solid product is the natural active ingredient of Epimedium; collect the evaporated ethanol, and reuse it after purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com