Preparation method of acetoxime methyl ether

A technology of acetone oxime methyl ether and acetone oxime, which is applied in the field of preparation of acetone oxime methyl ether, to achieve the effects of reducing cost and energy consumption, increasing yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

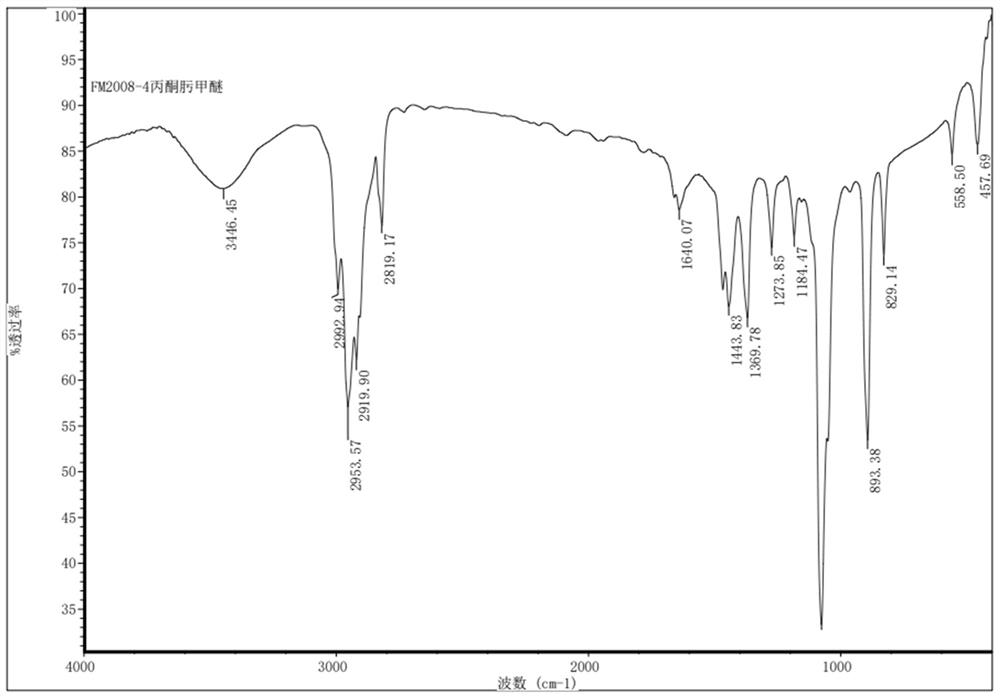

Image

Examples

Embodiment 1

[0028] A kind of preparation method of acetone oxime methyl ether, its scheme is:

[0029] Add 80kg of acetone oxime, 60kg of sodium hydroxide, 1kg of phase transfer catalyst and 600kg of toluene into the reactor, control the temperature at 40°C, mix and stir for 10min, then control the reaction temperature at 50°C, then start to feed 120kg of monochloromethane into the reactor, The control is completed within 30 minutes; then the heat preservation reaction is carried out for 10 minutes; after the reaction is completed, the crude solid sodium chloride is separated, the filtrate is pumped to the evaporator, heated to about 60°C with steam, and the acetone oxime methyl ether in the filtrate is evaporated The condenser condenses and flows into the crude product tank, and then the obtained acetone oxime methyl ether crude product is circulated and heated through the ether tower reboiler, and a small amount of water is condensed through the ether rectification tower condenser and fl...

Embodiment 2

[0037] A kind of preparation method of acetone oxime methyl ether, its scheme is:

[0038]Add 120kg of acetone oxime, 9kg of sodium hydroxide, 3kg of phase transfer catalyst and 700kg of toluene into the reactor, control the temperature at 50°C, mix and stir for 30min, then control the reaction temperature at 60°C, then start to feed 180kg of monochloromethane into the reactor, The control is completed within 40 minutes; then the heat preservation reaction is carried out for 20 minutes; after the reaction is completed, the crude solid sodium chloride is separated, the filtrate is pumped to the evaporator, heated to about 70°C with steam, and the acetone oxime methyl ether in the filtrate is evaporated The condenser condenses and flows into the crude product tank, and then the obtained acetone oxime methyl ether crude product is circulated and heated through the ether tower reboiler, and a small amount of water is condensed through the ether rectification tower condenser and flo...

Embodiment 3

[0046] A kind of preparation method of acetone oxime methyl ether, its scheme is:

[0047] Add 180kg of acetone oxime, 120kg of sodium hydroxide, 5kg of phase transfer catalyst and 800kg of toluene into the reactor, control the temperature at 60°C, mix and stir for 60min and then control the reaction temperature at 70°C, then start to feed 220kg of methylene chloride into the reactor, The control is completed within 60 minutes; then the heat preservation reaction is carried out for 30 minutes; after the reaction is completed, the crude solid sodium chloride is separated, the filtrate is pumped to the evaporator, heated to about 80°C with steam, and the acetone oxime methyl ether in the filtrate is evaporated The condenser condenses and flows into the crude product tank, and then the obtained acetone oxime methyl ether crude product is circulated and heated through the ether tower reboiler, and a small amount of water is condensed through the ether rectification tower condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com